Sugar granule mold cleaning device for throat lozenge production

A technology for cleaning devices and throat lozenges, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems affecting mold surface quality and service life, insufficient mold cleaning, etc., to achieve cleaning Sufficient and thorough, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

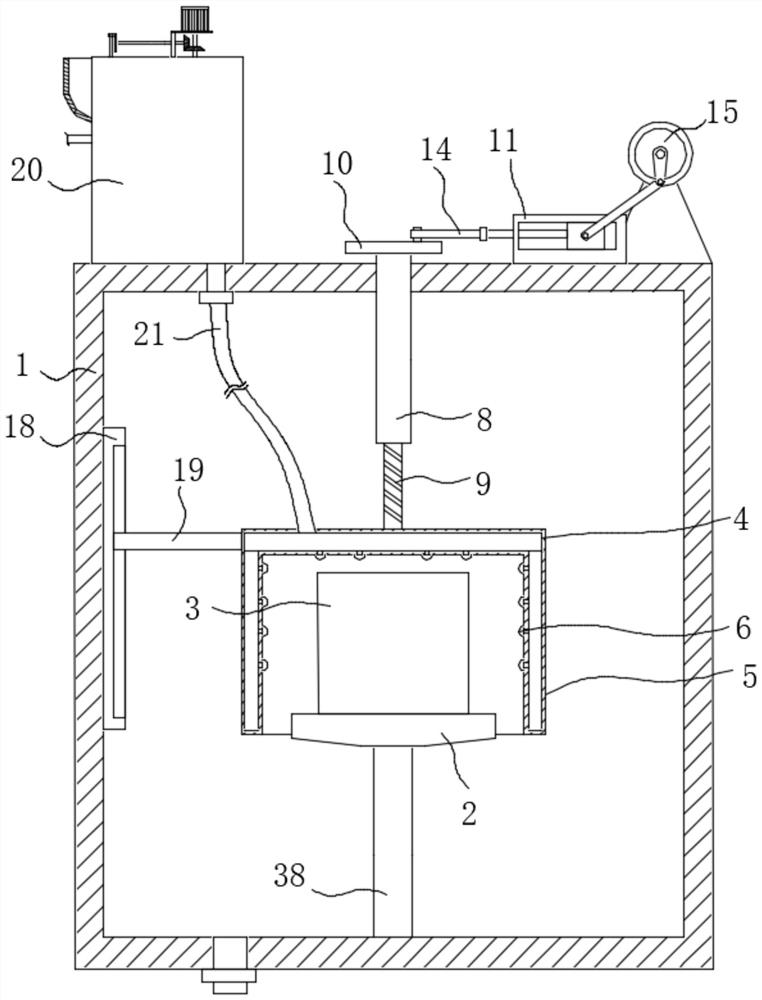

Embodiment 1

[0036] please combine Figure 1 to Figure 6 , a sugar granule mold cleaning device for throat lozenges production, comprising a box body 1, a carrier platform 2 for carrying the mold 3 is arranged in the box body 1, and a spray assembly for covering the mold 3 is arranged above the carrier platform 2 , the box body 1 is provided with a drive mechanism 1 for guiding the spray assembly to reciprocate in the vertical direction. The spray assembly can surround the carrier 2 and the periphery of the carrier mold 3 on the carrier 2 to realize multi-directional cleaning of the mold surface. In this embodiment, a box door 7 is installed on the front of the box body 1 to facilitate the insertion or removal of the mold 3 in the box body 1 .

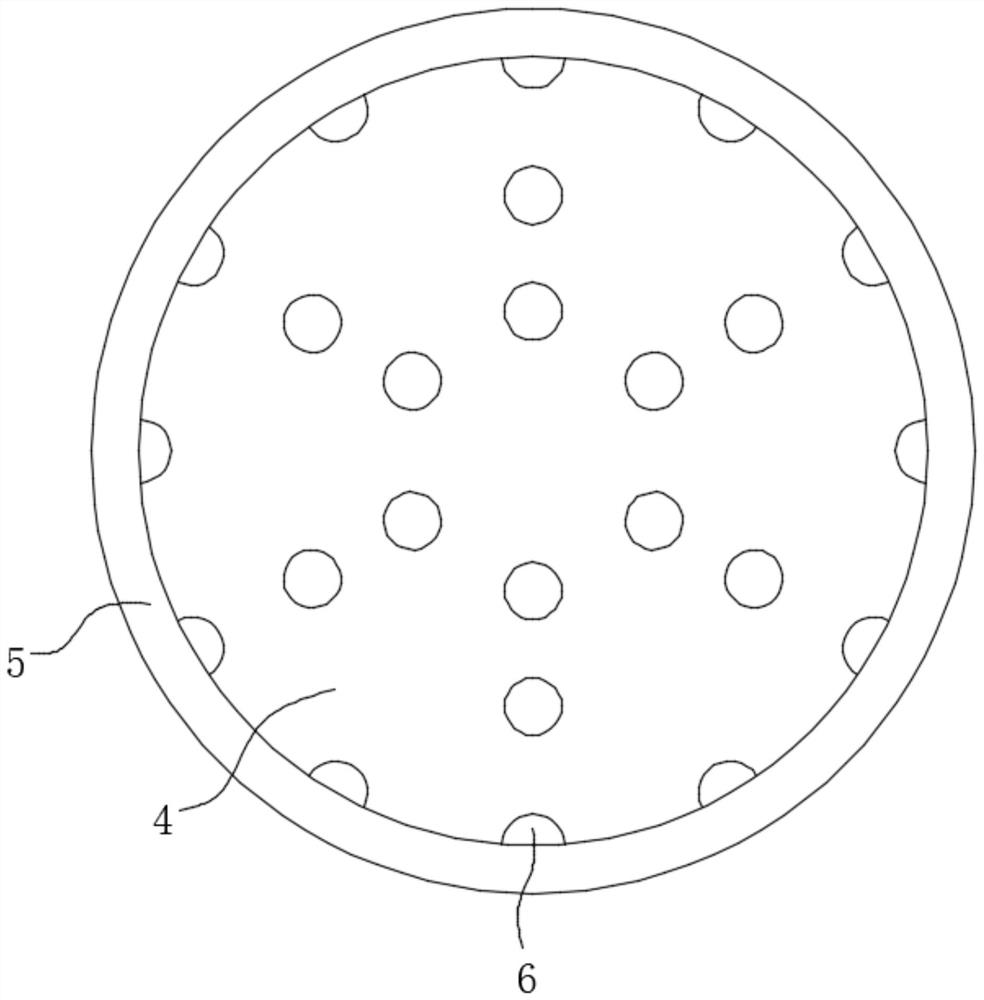

[0037] The spray assembly includes a top cover 4 with a circular cross section, a fixed cylinder 5 surrounding the mold 3 is arranged at the edge of the bottom of the top cover 4, and the side of the fixed cylinder 5 facing the carrier 2 has a hol...

Embodiment 2

[0049] please combine Figure 7 and Figure 8 The second embodiment is an improvement of the first embodiment. Specifically, a vertical shaft 37 is rotatably arranged in the box body 1 , and the bottom of the carrier 2 is rotatably supported in the box body 1 1 through the support column 38 . In this embodiment, the vertical shaft 37 , the support column 38 and the bottom of the box body 1 are rotatably connected by bearings, so the vertical shaft 37 and the support column 38 can rotate relatively in the box body 1 1 . The sleeve 8 and the vertical shaft 37 and the vertical shaft 37 and the support column 38 are connected by the pulley 36 and the belt drive.

[0050] In this embodiment, two pulleys 36 are sleeved on the shaft body of the vertical shaft 37 , and one pulley 36 is sleeved on each of the support column 38 and the sleeve 8 . The pulley 36 located at a higher position on the vertical shaft 37 and the pulley 36 of the sleeve 8 are connected by a belt drive, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com