Glass cleaning device

A glass cleaning and glass technology, which is applied in the direction of cleaning flexible objects, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problem of lack of uniform control standards for the amount of cleaning agents, restrictions on process control capabilities of process technology, and wet cleaning environments, etc. problems, achieve the effect of realizing standardized operations, improving the clean working environment, and improving the cleaning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

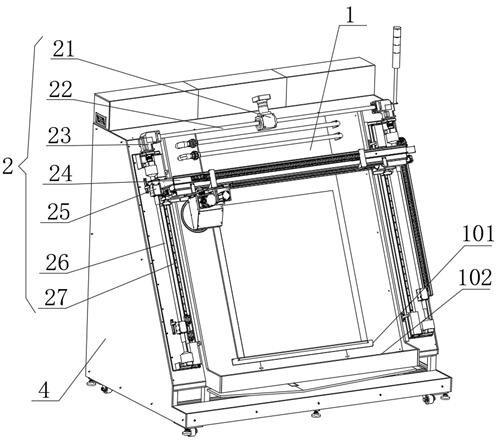

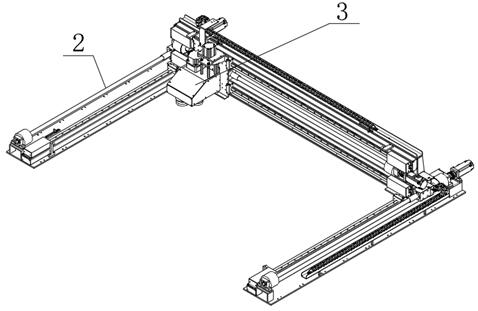

[0031] Such as figure 1 with figure 2 As shown, the glass cleaning device of this embodiment includes an adsorption panel 1, a longitudinal linear movement mechanism 2 installed above the surface of the adsorption panel 1, and a lateral movement module installed on the longitudinal linear movement mechanism 2, on which a brush head is installed. component 3;

[0032] The adsorption panel 1 is used to support and absorb the glass to be cleaned under negative pressure;

[0033] The vertical linear movement mechanism 2 includes a lateral movement module located above the adsorption panel 1 and moves longitudinally, and the brush head assembly 3 is installed on the lateral movement module and moves laterally;

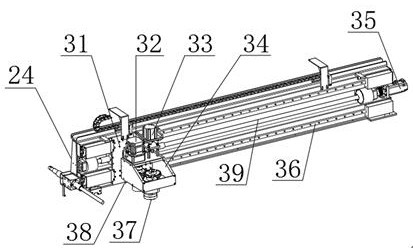

[0034] Such as image 3 As shown, the structure of the brush head assembly 3 includes a laterally moving plate 31, which is slidably mounte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com