Automobile part paint spraying device

A technology for auto parts and painting equipment, which is applied in the direction of spraying devices, chemical instruments and methods, cleaning methods and appliances, etc. It can solve the problems of affecting the quality of painting, poor linkage effect, scattered equipment, etc., to speed up painting efficiency and enhance practicality Quality, guaranteed cleanliness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]The technical solutions of the present invention will be better understood by those skilled in the art, and the invention will be further described in conjunction with the accompanying drawings.

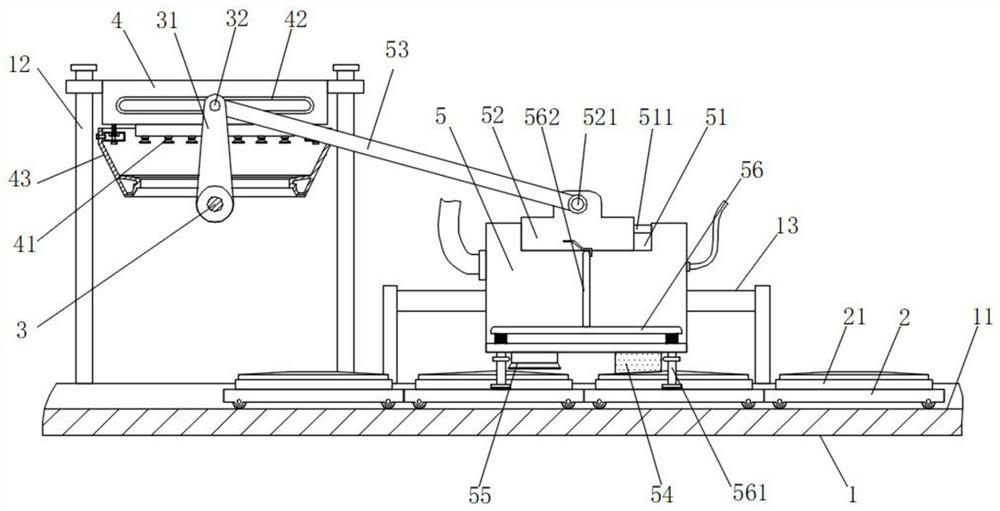

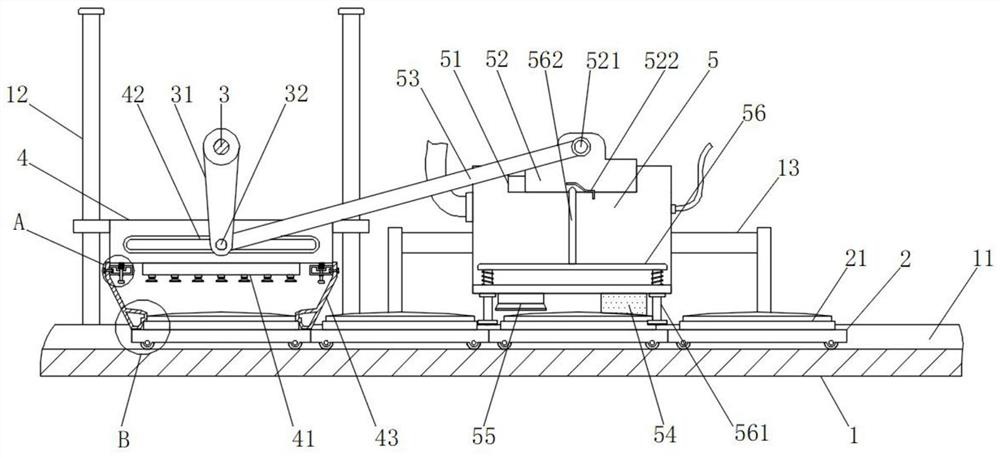

[0027]The present invention providesFigure 1-4 An auto parts, including a conveying base 1, and a conveying groove 11 is provided with a conveying groove 11 having a plurality of parts conveying plates 2, and the part conveying The top portion of the plate 2 is provided with a part casing 21, and the top portion of the conveying base 1 is provided with a drive shaft 3, the conveying base 1 fixed to a side of the drive shaft 3 fixedly connected to the motor holder 14, the drive shaft 3 rotates. Connected to the top of the motor rack 14, the driving motor 33 is attached to the outside of the motor holder 14, the drive motor 33 is driven by the output shaft and the drive shaft 3, and the inner end of the drive shaft 3 is fixedly installed with a rocker. 31. The rocker 31 is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com