Ore dressing process for sorting zirconite by classification jigger

A technology of zircon and jig, which is applied in the field of mineral processing, can solve the problems of low grade, poor mineral processing effect, and difficulty in comprehensive recovery, etc., and achieve the effect of increasing hydrophobicity and improving adhesion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

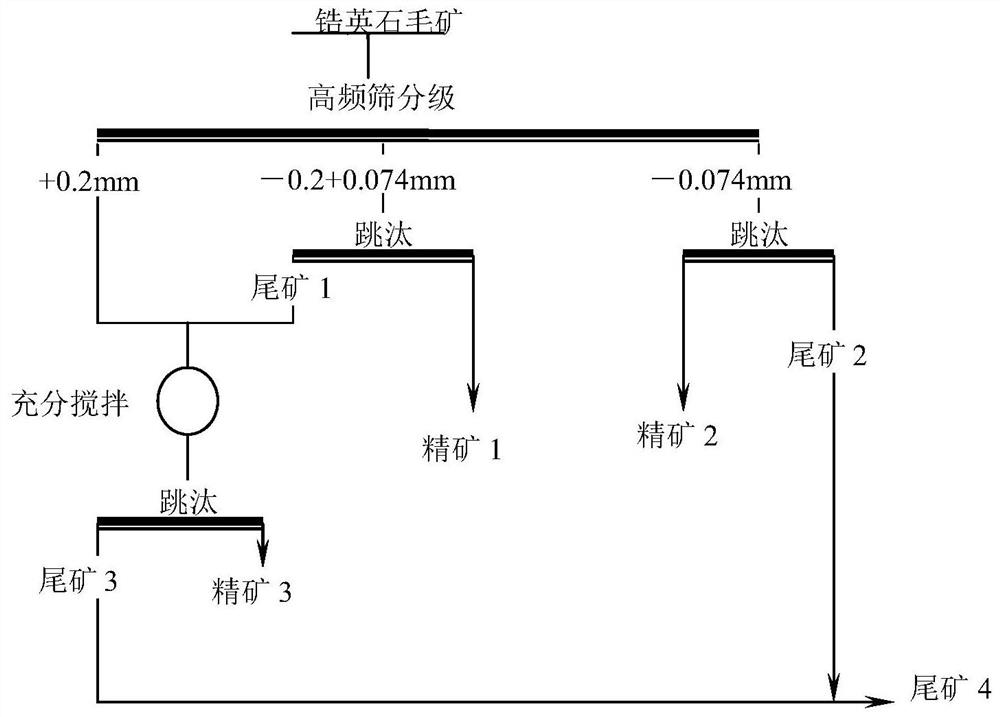

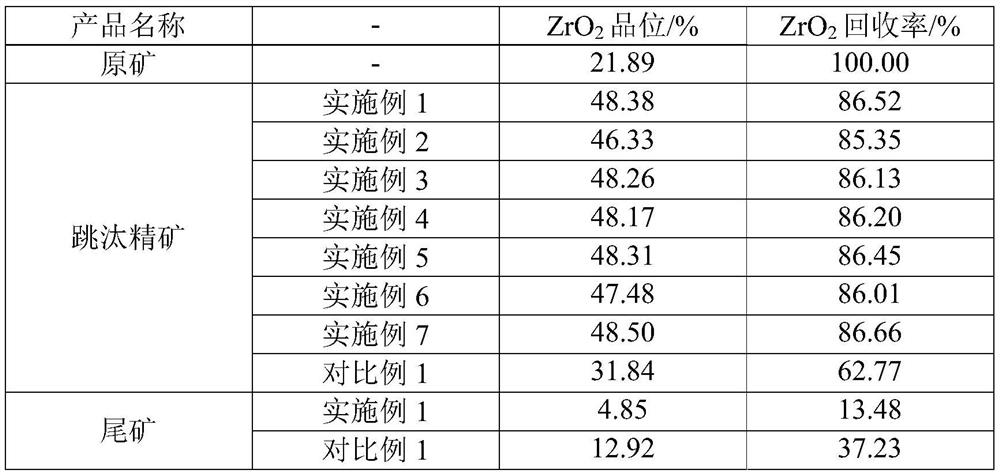

[0028] A grading jig sorting zircon beneficiation process, comprising the following steps:

[0029] (1) Use a high-frequency vibrating sieve to classify the raw materials into minerals of three particle sizes of +0.2mm, -0.2+0.074mm and -0.074mm;

[0030] (2) Minerals with grain size of -0.2+0.074mm are subjected to jigging treatment (stroke is 90mm, punching frequency is 150 times / min) to obtain concentrate 1 and tailings 1, and minerals with grain size of -0.074mm are obtained through jigging treatment concentrate 2 and tailings 2;

[0031] (3) Tailings 1 is combined with minerals of +0.2mm size, and processed by jigging (120mm stroke, 200 strokes / minute) to obtain concentrate 3 and tailings 3;

[0032] (4) Concentrate 1, concentrate 2 and concentrate 3 are combined into zircon jigging concentrate, and tailings 2 and tailings 3 are combined into tailings 4 .

Embodiment 2

[0034] A grading jig sorting zircon beneficiation process, comprising the following steps:

[0035] (1) Use a high-frequency vibrating sieve to classify the raw materials into minerals of three particle sizes of +0.2mm, -0.2+0.074mm and -0.074mm;

[0036] (2) Minerals with grain size of -0.2+0.074mm are subjected to jigging treatment (60 strokes, 130 strokes / min) to obtain concentrate 1 and tailings 1, and minerals with grain size of -0.074mm are obtained through jigging treatment concentrate 2 and tailings 2;

[0037] (3) The tailings 1 is combined with the minerals of +0.2mm size, and after jigging (90mm stroke, 150 strokes / min), concentrate 3 and tailings 3 are obtained;

[0038] (4) Concentrate 1, concentrate 2 and concentrate 3 are combined into zircon jigging concentrate, and tailings 2 and tailings 3 are combined into tailings 4 .

Embodiment 3

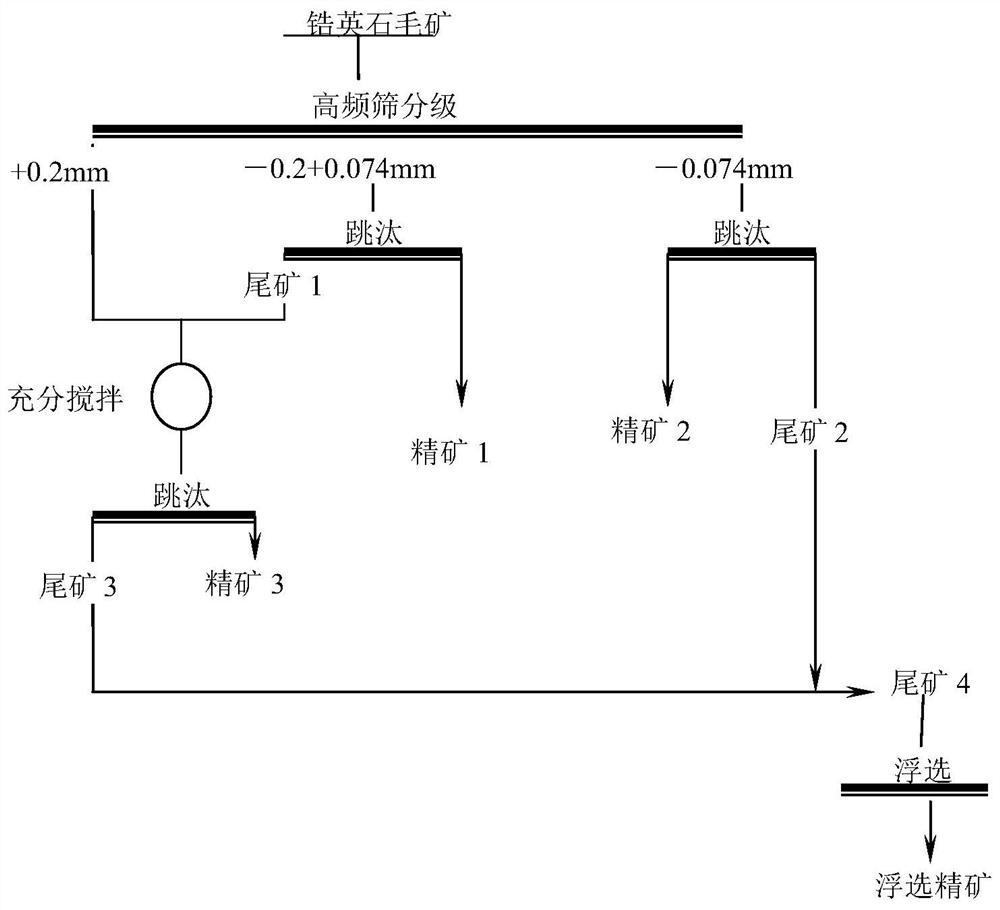

[0040] The difference between this example and embodiment 1 is:

[0041] The tailings 4 of Example 1 were made into slurry with a mass concentration of 50%, and flotation reagents were added to perform flotation for at least 20 minutes to obtain a flotation concentrate, and all the concentrates were combined. The dosage of flotation reagents is: dextrin 100g / t pulp, sodium humate 200g / t pulp, caustic soda 50g / t pulp, sodium oleate 60g / t pulp, nitrilotriacetic acid sodium 100g / t pulp, copper chloride 50g / t pulp, rhamnolipid 12g / t pulp, carboxymethyl cellulose sodium 4g / t pulp.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com