Energy-saving tobacco baking device and using method thereof

A baking device, energy-saving technology, applied in tobacco, tobacco preparation, application, etc., can solve the problems of heavy pollution, increased labor intensity of workers, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

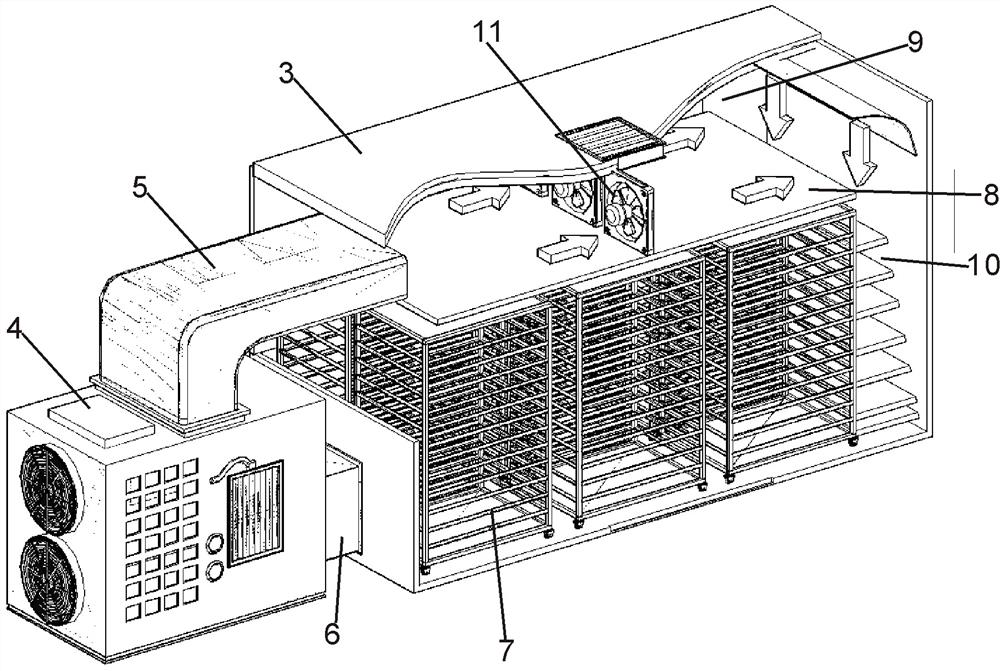

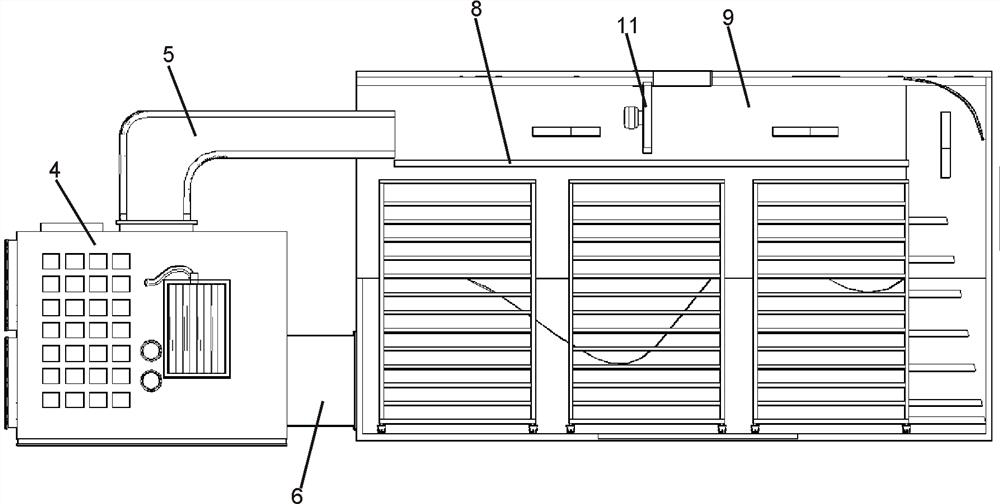

[0045] By the following Figure 1 - Figure 8 The present invention will be described in detail, and the technical solutions in the embodiments of the present invention will be described, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

[0046] The present invention provides an energy-saving tobacco baking apparatus by improving it. Figure 1 - Figure 8 As shown, it can be implemented as follows; the tobacco baking apparatus includes a tobacco baking body 1, and the front surface of the tobacco baking body 1 forms an ingoing air region, and the back surface is provided on the door 2;

[0047] The tobacco baking apparatus also includes an insulation housing 3, which is integrally mounted to the tobacco baking body 1;

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com