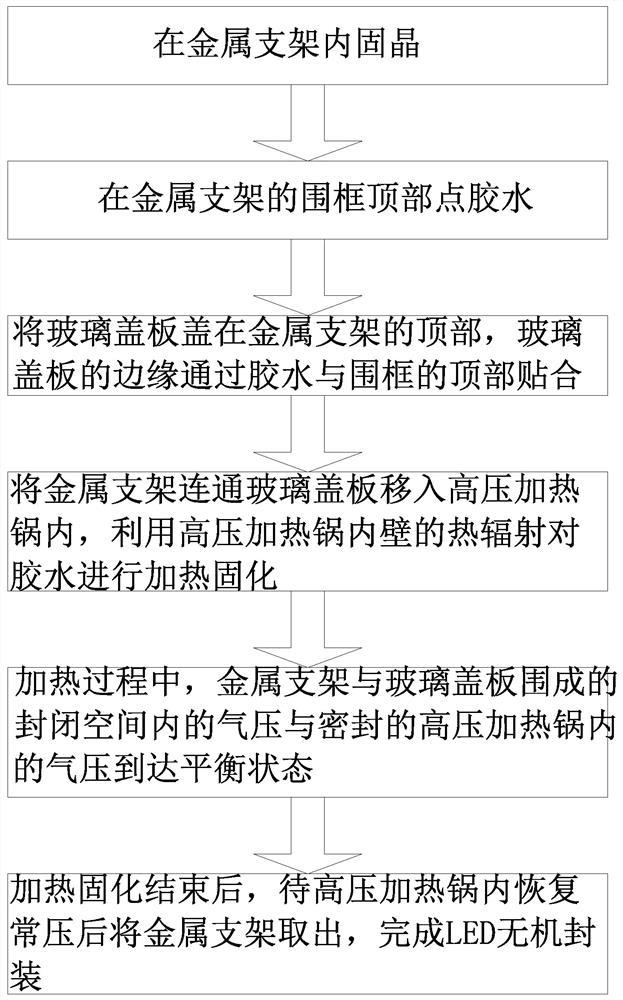

LED inorganic packaging method

A packaging method and inorganic technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problem of airway left in sealant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings of the description.

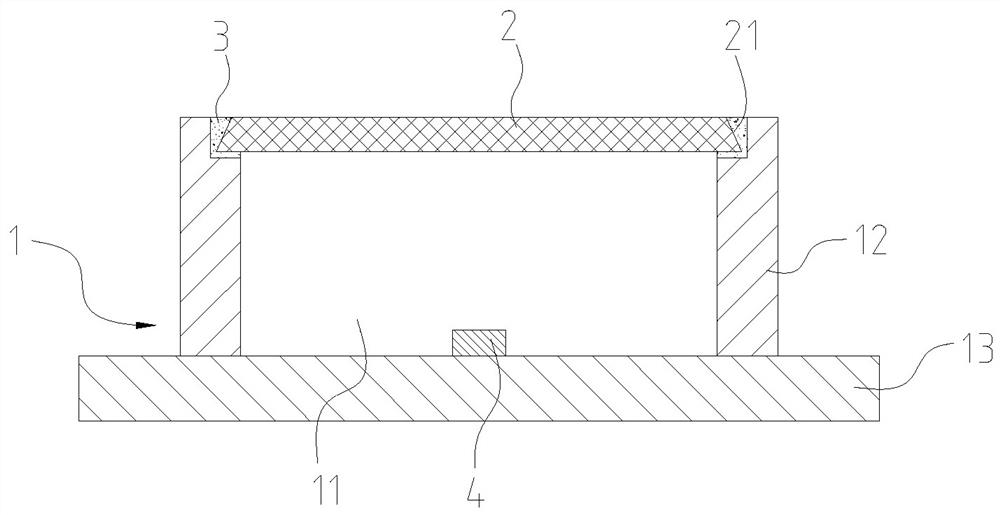

[0022] Such as figure 1 As shown, an LED inorganic packaging structure includes a metal support 1 and a glass cover 2 covering the metal support 1 . The metal support 1 includes a ceramic substrate 13 and a surrounding frame 12 arranged on the ceramic substrate 13; a groove is arranged on the inner side of the top of the surrounding frame 12, and the edge of the glass cover plate 2 is arranged in the groove, and the glass cover 2 The top of the plate 2 is flush with the top of the surrounding frame 12; the groove is provided with glue 3, and the glass cover 2 cooperates with the metal bracket 1 to form a closed space 11; the edge of the glass cover 2 is a bevel 21, The glue 3 covers the edge of the glass cover 2, and the bevel 21 on the edge of the glass cover 2 makes the contact area with the glue larger. Meanwhile, the glue 3 is pressed on the bev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com