5G signal transmitter capacitor formed foil multistage oxidation treatment process and production line thereof

A signal transmitter and oxidation treatment technology, which is applied in the direction of capacitors, capacitor manufacturing, electrolytic capacitors, etc., to achieve the effects of shortening the working hours of converting product specifications, saving electric energy, and reducing current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

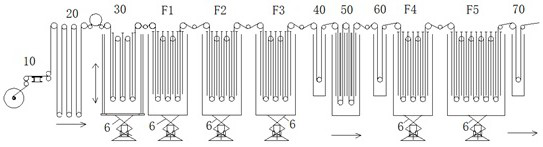

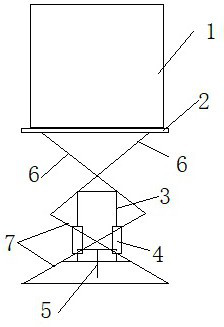

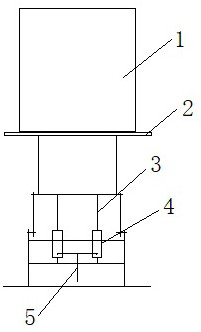

Image

Examples

Embodiment 1

[0035] An embodiment of the capacitor forming foil multi-stage oxidation treatment process, the specific implementation steps are as follows:

[0036] (1) Pretreatment: Put the corroded aluminum foil with a purity of 99.99wt% in pure water at a temperature of 97°C for 12 minutes;

[0037] (2) Primary formation: immerse the pretreated aluminum foil in an aqueous solution containing 1wt% phosphoric acid, 5wt% oxalic acid, and 4wt% ammonium dihydrogen phosphate, and form it under the conditions of 85°C, 10mA / cm2, and 120V for 6 minutes;

[0038] (3) Secondary formation: immerse the aluminum foil after primary formation in an aqueous solution containing 0.5wt% phosphoric acid, 2wt% oxalic acid, and 2wt% ammonium dihydrogen phosphate, and form under the conditions of 85°C, 10mA / cm2, and 250V for 6 minutes ;

[0039] (4) Tertiary formation: immerse the aluminum foil after the secondary formation in an aqueous solution containing 3wt% boric acid, 0.5wt% ammonium dihydrogen phosphate...

Embodiment 2

[0044] Different from Embodiment 1, another embodiment of the capacitor formation foil multi-stage oxidation treatment process, the specific implementation steps are as follows:

[0045] (1) Pretreatment: Put corroded aluminum foil with a purity of 99.99wt% in pure water at a temperature of 98°C for 9 minutes;

[0046] (2) Primary formation: immerse the pretreated aluminum foil in an aqueous solution containing 2.5wt% phosphoric acid, 3wt% oxalic acid, and 3wt% ammonium dihydrogen phosphate, and form it under the conditions of 86°C, 8mA / cm2, and 123V for 6.5min ;

[0047] (3) Secondary formation: immerse the aluminum foil after primary formation in an aqueous solution containing 1wt% phosphoric acid, 3wt% oxalic acid, and 3wt% ammonium dihydrogen phosphate, and form under the conditions of 86°C, 8mA / cm2, and 245V for 6.5min ;

[0048] (4) Tertiary formation: immerse the aluminum foil after the secondary formation in an aqueous solution containing 5wt% boric acid, 1wt% ammoni...

Embodiment 3

[0053] Different from Embodiment 1, another embodiment of the capacitor formation foil multi-stage oxidation treatment process, the specific implementation steps are as follows:

[0054] (1) Pretreatment: Put corroded aluminum foil with a purity of 99.99wt% in pure water at a temperature of 96.5°C for 10 minutes;

[0055] (2) Primary formation: immerse the pretreated aluminum foil in an aqueous solution containing 2wt% phosphoric acid, 4wt% oxalic acid, and 5wt% ammonium dihydrogen phosphate, and form it at 87°C, 9mA / cm2, and 126V for 7 minutes;

[0056] (3) Secondary formation: immerse the aluminum foil after primary formation in an aqueous solution containing 0.6wt% phosphoric acid, 2wt% oxalic acid, and 2.5wt% ammonium dihydrogen phosphate, and form under the conditions of 87°C, 9mA / cm2, and 255V 7min;

[0057] (4) Tertiary formation: immerse the aluminum foil after secondary formation in an aqueous solution containing 3wt% boric acid, 0.5wt% ammonium dihydrogen phosphate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com