5g signal transmitter capacitor forming foil multi-stage oxidation treatment process and its production line

A signal transmitter, oxidation treatment technology, used in capacitors, capacitor manufacturing, electrolytic capacitors, etc., to achieve the effects of large ripple current resistance, low leakage, and low leakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

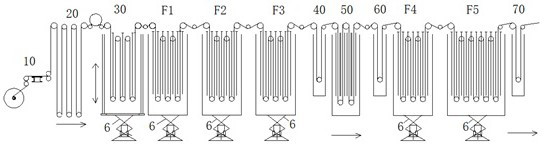

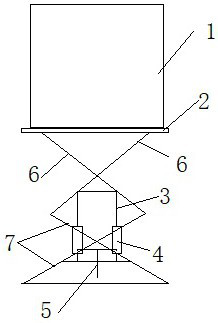

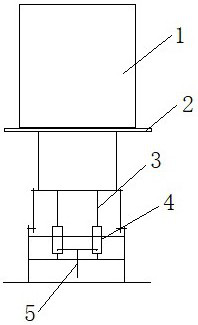

Image

Examples

Embodiment 1

[0035] An embodiment of the capacitor forming foil multi-stage oxidation treatment process, the specific implementation steps are as follows:

[0036] (1) Pretreatment: Put the corroded aluminum foil with a purity of 99.99wt% in pure water at a temperature of 97°C for 12 minutes;

[0037] (2) Primary formation: immerse the pretreated aluminum foil in an aqueous solution containing 1wt% phosphoric acid, 5wt% oxalic acid, and 4wt% ammonium dihydrogen phosphate, and form it under the conditions of 85°C, 10mA / cm2, and 120V for 6 minutes;

[0038] (3) Secondary formation: immerse the aluminum foil after primary formation in an aqueous solution containing 0.5wt% phosphoric acid, 2wt% oxalic acid, and 2wt% ammonium dihydrogen phosphate, and form under the conditions of 85°C, 10mA / cm2, and 250V for 6 minutes ;

[0039] (4) Tertiary formation: immerse the aluminum foil after the secondary formation in an aqueous solution containing 3wt% boric acid, 0.5wt% ammonium dihydrogen phosphate...

Embodiment 2

[0044] Different from Embodiment 1, another embodiment of the capacitor formation foil multi-stage oxidation treatment process, the specific implementation steps are as follows:

[0045] (1) Pretreatment: Put corroded aluminum foil with a purity of 99.99wt% in pure water at a temperature of 98°C for 9 minutes;

[0046] (2) Primary formation: immerse the pretreated aluminum foil in an aqueous solution containing 2.5wt% phosphoric acid, 3wt% oxalic acid, and 3wt% ammonium dihydrogen phosphate, and form it under the conditions of 86°C, 8mA / cm2, and 123V for 6.5min ;

[0047] (3) Secondary formation: immerse the aluminum foil after primary formation in an aqueous solution containing 1wt% phosphoric acid, 3wt% oxalic acid, and 3wt% ammonium dihydrogen phosphate, and form under the conditions of 86°C, 8mA / cm2, and 245V for 6.5min ;

[0048] (4) Tertiary formation: immerse the aluminum foil after the secondary formation in an aqueous solution containing 5wt% boric acid, 1wt% ammoni...

Embodiment 3

[0053] Different from Embodiment 1, another embodiment of the capacitor formation foil multi-stage oxidation treatment process, the specific implementation steps are as follows:

[0054] (1) Pretreatment: Put corroded aluminum foil with a purity of 99.99wt% in pure water at a temperature of 96.5°C for 10 minutes;

[0055] (2) Primary formation: immerse the pretreated aluminum foil in an aqueous solution containing 2wt% phosphoric acid, 4wt% oxalic acid, and 5wt% ammonium dihydrogen phosphate, and form it at 87°C, 9mA / cm2, and 126V for 7 minutes;

[0056] (3) Secondary formation: immerse the aluminum foil after primary formation in an aqueous solution containing 0.6wt% phosphoric acid, 2wt% oxalic acid, and 2.5wt% ammonium dihydrogen phosphate, and form under the conditions of 87°C, 9mA / cm2, and 255V 7min;

[0057] (4) Tertiary formation: immerse the aluminum foil after secondary formation in an aqueous solution containing 3wt% boric acid, 0.5wt% ammonium dihydrogen phosphate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com