Air source heat pump curing barn energy-saving control method, storage medium and energy-saving curing barn

An air source heat pump, energy-saving control technology, applied in the direction of drying gas arrangement, lighting and heating equipment, local stirring and drying machine, etc., can solve the problems of room temperature and humidity index of single material, poor energy-saving effect, and lack of establishment of operation mechanism, etc. Achieve the effect of highlighting the effect of energy saving and emission reduction, good energy saving effect, and improvement of the quality of material preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: (applied to the environment with daily average temperature ≥ 25°C)

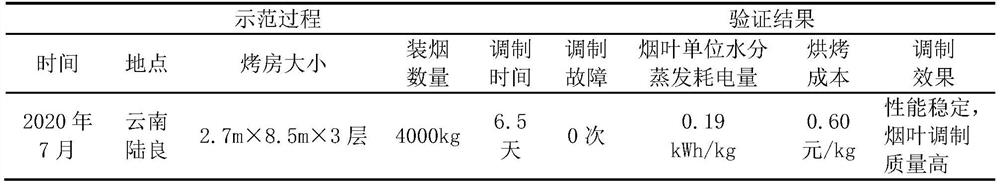

[0032] The verification process and results are shown in Table 1.

[0033] Table 1 The air source heat pump barn energy-saving control method, storage medium and energy-saving barn of the present invention are applied to the raw tobacco leaf modulation process and results in an environment with a daily average temperature ≥ 25°C

[0034]

[0035] An air-source heat pump barn energy-saving control method, storage medium and energy-saving barn invented by this technology are applied to prepare tobacco leaves in an environment with an average daily temperature ≥ 25°C. The power consumption is 632 degrees, and the power consumption per unit moisture evaporation of tobacco leaves: 0.19kWh / kg; baking cost: 0.60 yuan / kg of first-cured tobacco leaves.

[0036] Modulation cost accounting: Compared with the cost of flue-cured tobacco modulation in large-area air source heat pump barns, it saves...

Embodiment 2

[0039] Embodiment 2: (applied to the environment with daily average temperature<25°C)

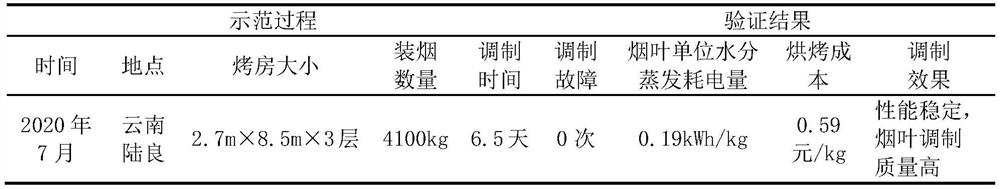

[0040] The verification process and results are shown in Table 2.

[0041] Table 2 The air source heat pump barn energy-saving control method, storage medium and energy-saving barn of the present invention are applied to the tobacco leaf modulation process and results in an environment with an average daily temperature of <25°C

[0042]

[0043] An air source heat pump barn energy-saving control method, storage medium and energy-saving barn invented by this technology are applied to prepare tobacco leaves in an environment where the daily average temperature is less than 25°C. The power consumption is 641 degrees, and the power consumption per unit moisture evaporation of tobacco leaves: 0.19kWh / kg; baking cost: 0.59 yuan / kg of first-cured tobacco leaves.

[0044] Modulation cost accounting: Compared with the cost of flue-cured tobacco modulation in large-area air source heat pump barns...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com