A high pressure blower

A fan and high-pressure technology, applied in the field of fan applications, can solve the problems of reducing the rigidity of the moving blade, increasing the deformation of the moving blade, unfavorable blade tip clearance control, etc., to achieve reduced manufacturing costs, corrosion-resistant manufacturing costs, and low secondary flow loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

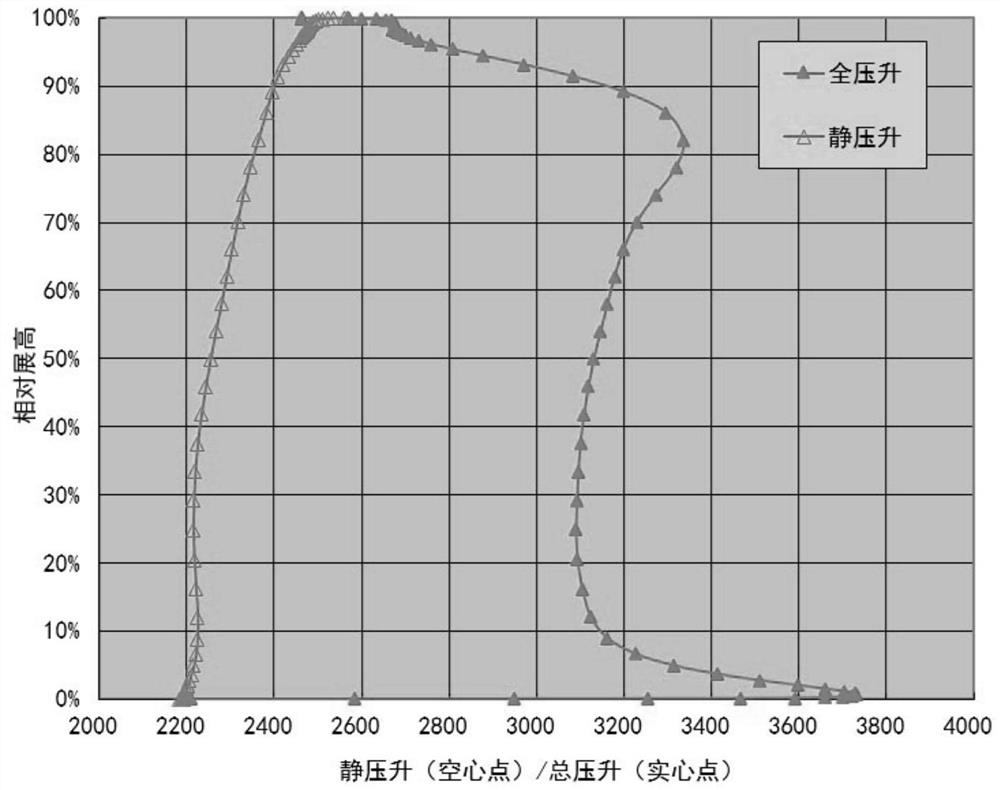

Image

Examples

Embodiment 1

[0031] see Figure 1-3 , the present invention provides a high-voltage booster, including an intermediate frequency motor 1, a moving impeller 2, a rectifier 3, an intake cone 4 and an air duct assembly 5, and the rectifier 3 is fixed on the end face of one side of the intermediate frequency motor 1 by screws, so The moving impeller 2 is installed on the motor shaft of the intermediate frequency motor 1, and is limited by the cap, the intake cone 4 is fixedly connected to the moving impeller 2 by screws, and the air duct assembly 5 includes an intake air duct 5- 1 and an exhaust air duct 5-2, the intake air duct 5-1 is correspondingly sleeved with the intake cone 4 and the moving impeller 2, and the exhaust air duct 5-2 is sleeved correspondingly with the intermediate frequency motor 1, and The intake air duct 5-1 and the exhaust air duct 5-2 are fixedly connected by screws, and the moving impeller 2 is integrally formed by a first hub 2-1, a wheel disc 2-2 and a moving blade ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com