Mining system and mining method of pseudo-dipping layout in steeply inclined coal seam mining area

A pseudo-incline and steep inclination technology, applied in ground mining, mining equipment, underground mining, etc., can solve problems such as high degree of equipment dependence, limited working face length, flying gangue on the working face, etc., to achieve long-term operation, The effect of improving ventilation conditions and coal mining safety, and reducing the time for transportation and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

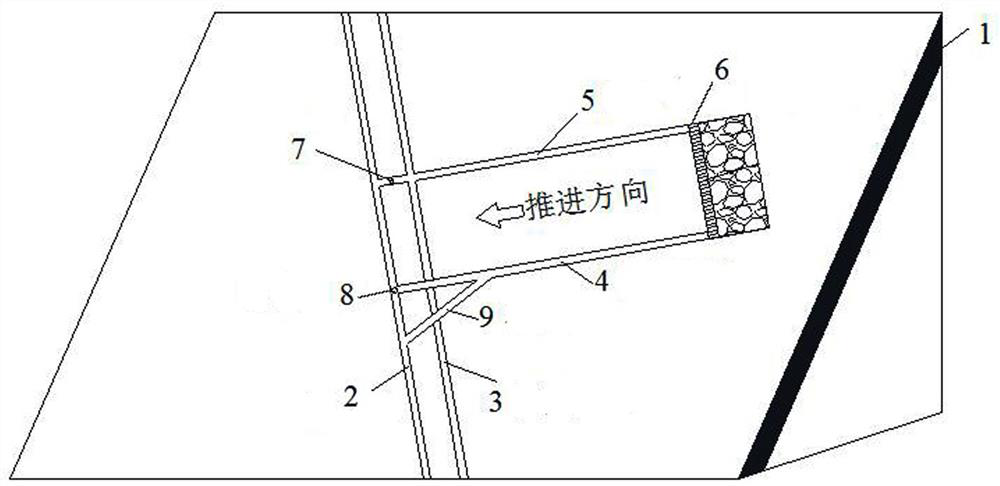

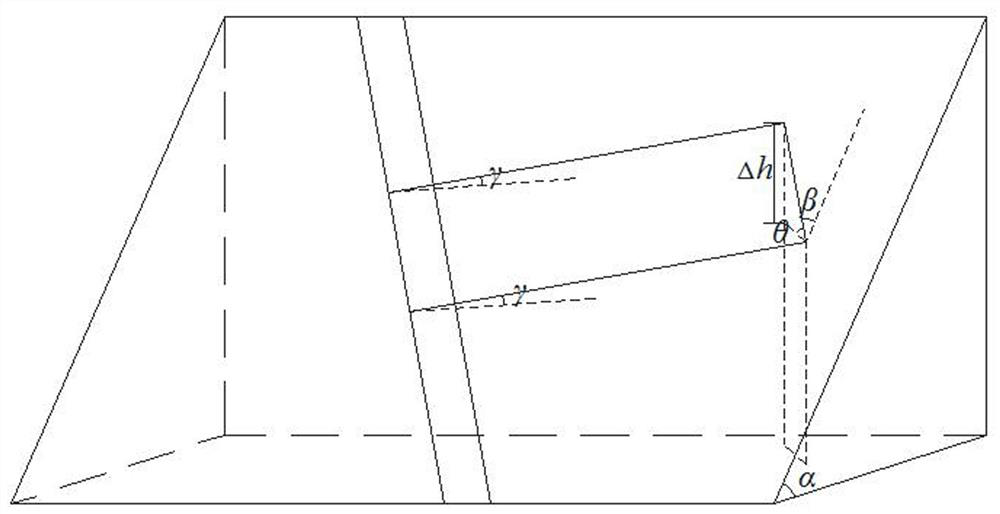

[0034] Example 1 A mining system with pseudo-inclined layout in a steeply inclined coal seam mining area

[0035] Such as figure 1 As shown, this embodiment includes a working face 6, a transport lane 4, a return air lane 5, a return wind uphill 3 and a transport uphill 2, wherein the working face 6 is arranged in a pseudo-sloping manner with the upper end ahead, and the working face 6 is provided with The coal mining machine, the scraper conveyor and the hydraulic support used for support, the advancing direction of the working face 6 is backwardly advancing along the direction perpendicular to the working face 6 . In this embodiment, the scraper conveyor is used to transport the coal mined by the shearer to the transportation lane 4. The hydraulic support can effectively control the deformation of the coal wall and roof in front, and prevent the occurrence of sidewalls and roof fall. The advancement of working face 6 adopts retreat mining, that is, the advancing direction ...

Embodiment 2

[0045] Example 2 A mining method of pseudo-sloping layout in a steeply inclined coal seam mining area

[0046] According to Embodiment 1, this embodiment provides a mining method for a pseudo-inclined mining area in a steeply inclined coal seam, including the following steps:

[0047] S1. Coal is mined by a shearer on the working face 6, and the coal is transported to the transport lane 4 by a scraper conveyor;

[0048] S2. The coal mined at the working face 6 passes through the transport lane 4 and then passes through the coal sliding hole 8, enters the transport uphill 2, and then transports the coal out;

[0049]Among them, the ventilation is continued during steps S1 and S2, and the ventilation route is as follows: the fresh air flows through the transportation uphill 2 and enters the transportation alley 4 along the Shimen 9, and then enters the working face 6, becomes dirty air and enters the return air uphill through the return air alley 5 3. The continuous ventilatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com