Drill carriage device for intelligently and automatically feeding drill rods for coal mine

A drill pipe and intelligent technology, which is applied to the field of drilling rig devices for intelligent automatic drill pipe loading in coal mines, can solve the problems such as the reduction of work efficiency by automatic rod loading, the inability to seal the top surface of the drill pipe box, and the influence on the grasping of the drill pipe. Beneficial for drilling, small footprint, and useful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

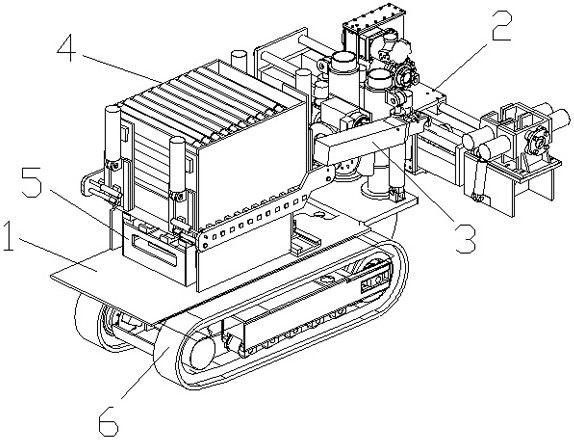

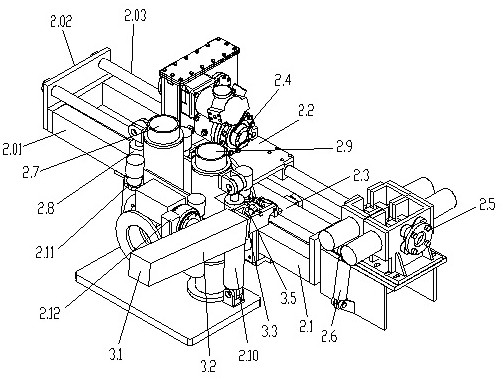

[0042] see Figure 1-Figure 15 , figure 1 A structural schematic diagram of an intelligent automatic drill pipe loading device for coal mines is drawn. As shown in the figure, an intelligent automatic drilling rig for coal mines according to the present invention includes a main machine body 1, a working mechanism 2, a drill box 4 for storing drill rods 7, a drill rod transport frame 5, and crawler belts. device 6 and mechanical arm 3; the crawler belt walking device 6 is fixed on both sides of the main engine body 1 and contacts with the ground, and is used to move the main engine body 1; Drill pipe delivery frame 5 is arranged.

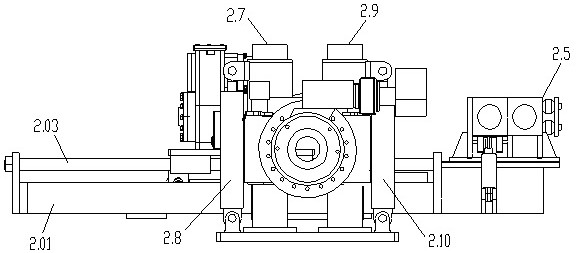

[0043] see Figure 2-Figure 5 , the working mechanism 2 includes a sliding frame 2.1, a sliding seat 2.2, a power head 2.3 and a clamper 2.5, the sliding frame 2.1 includes a base 2.01, the front end and the rear end of the base 2.01 are provided with a base 2.02, and the front and rear bases Two left and right support rods 2.03 are arranged bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com