Steel storage bin top feeding auxiliary structure

A technology of auxiliary structure and storage silo, applied in the direction of large-capacity bulk material storage, building type, building, etc., can solve problems such as reducing service life, and achieve the effect of convenient construction, solving service life and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings, but the implementation scope of the present invention is not limited by the embodiments.

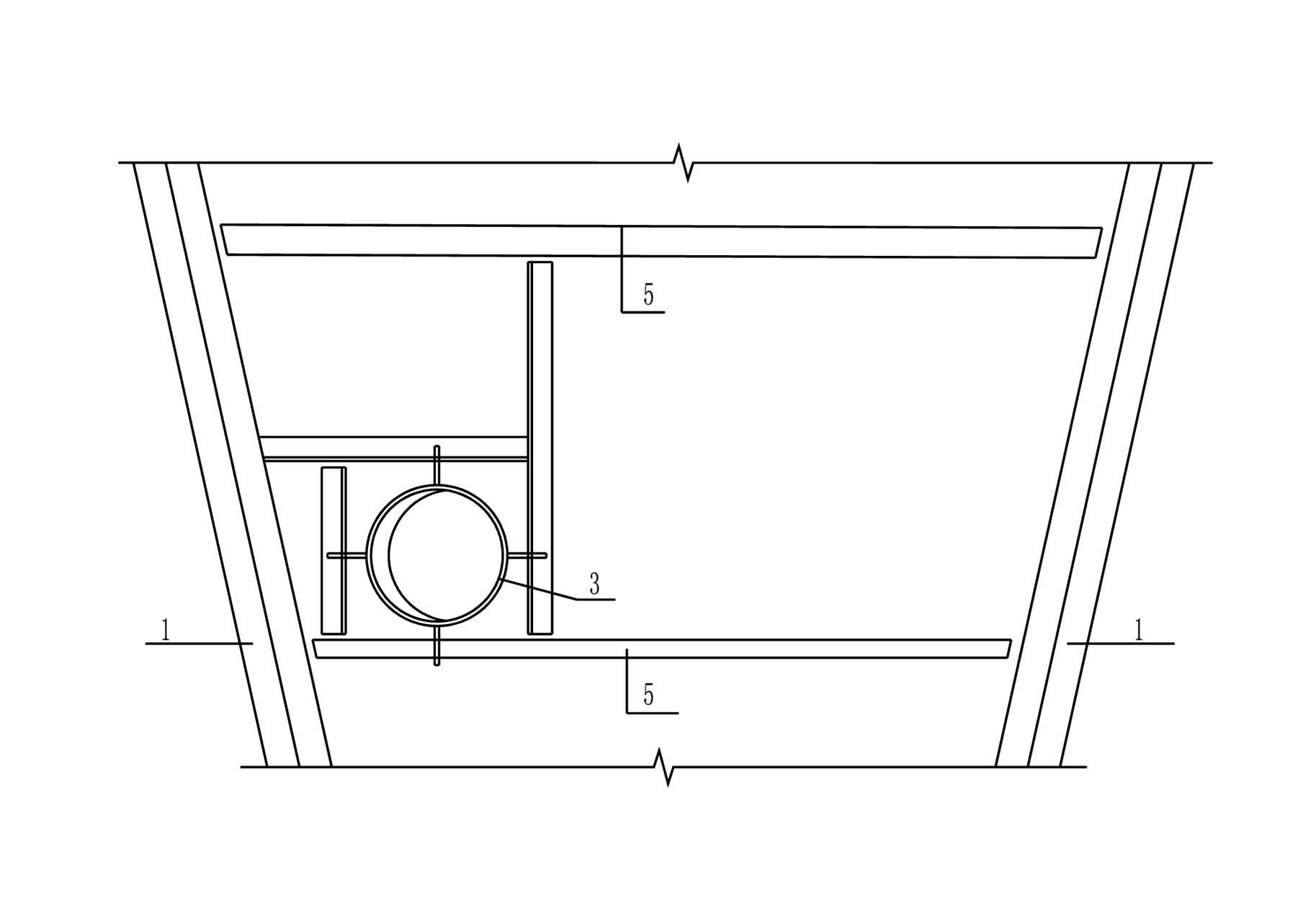

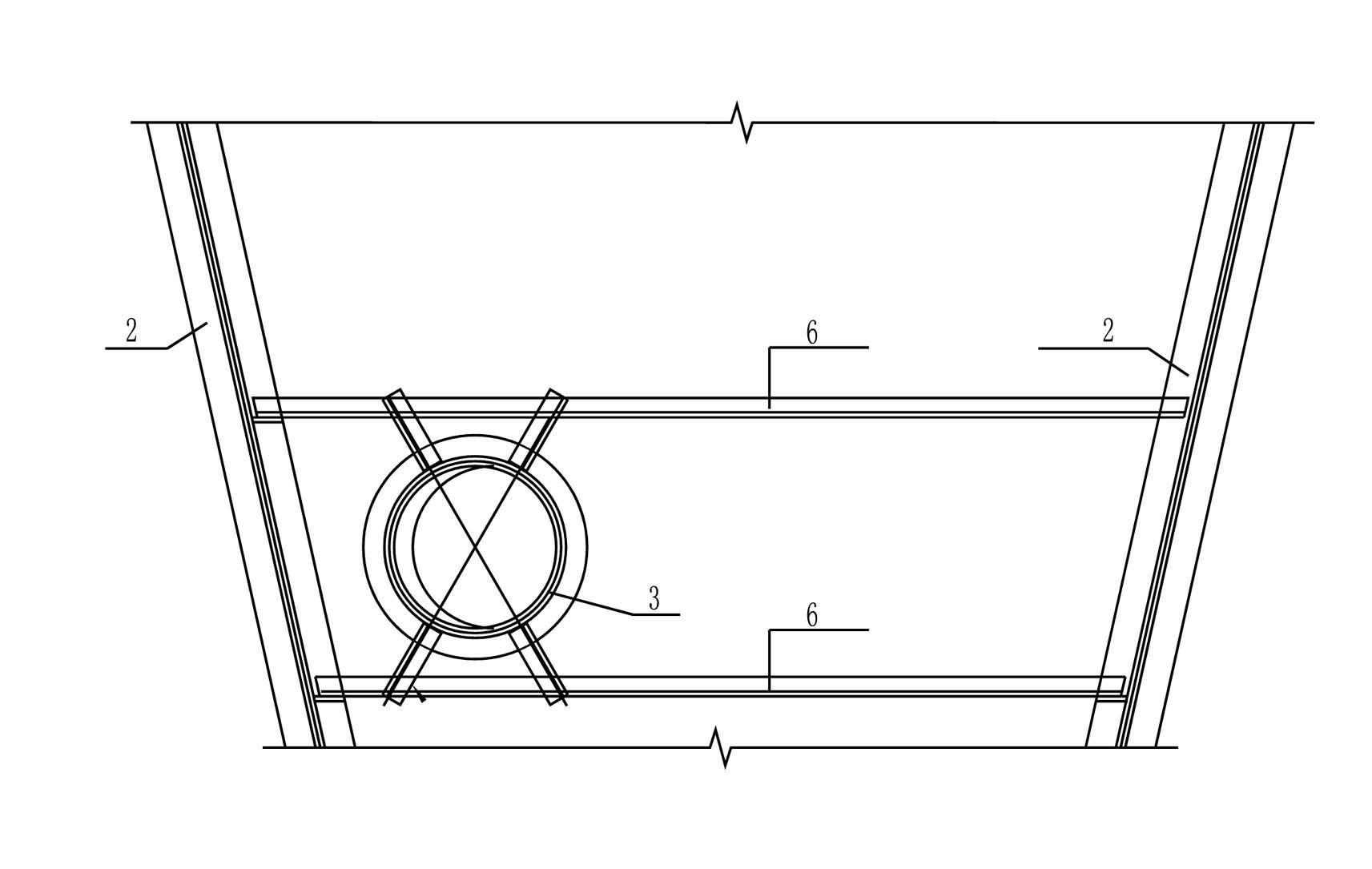

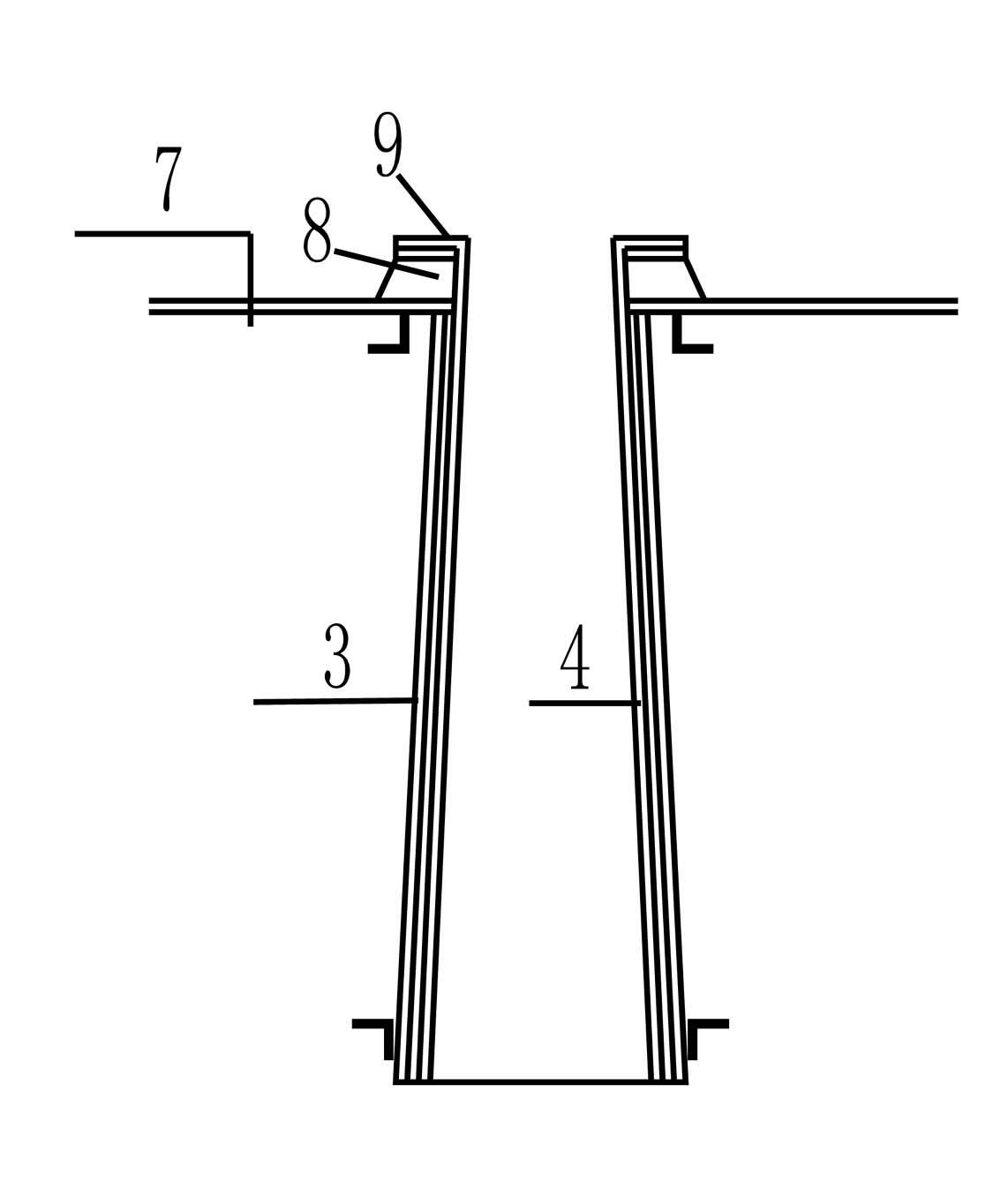

[0018] As shown in the figure, the steel silo roof blanking auxiliary structure of the present invention includes the upper chord 1 of the roof support truss, the lower chord 2 of the roof support truss and the roof plate 7, between the upper chord 1 of the roof support truss and the lower chord 2 of the roof support truss A variable-diameter outer steel pipe 3 is welded between them to ensure that the variable-diameter outer steel pipe can be fixed on the support structure of the warehouse roof. A variable-diameter inner steel pipe 4 that can be The steel pipe 3 constrains the displacement of the variable-diameter inner steel pipe 4, the upper end of the variable-diameter outer steel pipe 3 is welded to the upper chord 1 of the roof support truss through the upper steel beam 5, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com