Microfluidic spinning device, linear core-shell structure conductive fiber and preparation method and application of linear core-shell structure conductive fiber

A technology of spinning device and core-shell structure, which is applied in the field of microfluidic spinning device, can solve the problems of simple and rough, lack of conductive properties of conductive materials, and inability to control the shape accurately, and achieve low cost and excellent photothermal shrinkage performance , the effect of excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A linear core-shell structure MXene conductive fiber, comprising the steps of:

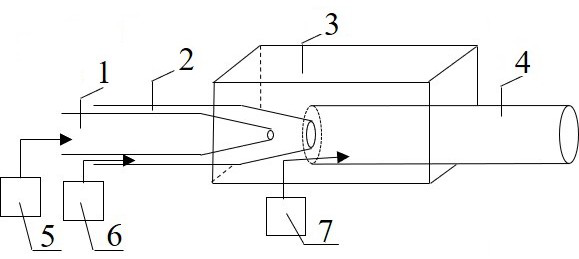

[0034] S1. Assemble the microfluidic spinning device: refer to figure 1 , assemble the internal phase capillary 1, the intermediate phase capillary 2, and the external phase capillary 4 with inner diameters of 100 μm, 250 μm, and 800 μm coaxially into the observation capillary 3, where necessary (the interface between the internal phase capillary 1 and the intermediate phase capillary 2, the middle The interface between the phase capillary 2 and the observation capillary 3, and the interface between the outer phase capillary 4 and the observation capillary 3) are encapsulated with transparent epoxy resin; then the inner phase capillary 1 is connected with the inner phase liquid inlet device 5 to form an inner phase fluid flow pipeline, and the middle The phase capillary 2 is connected with the intermediate phase liquid inlet device 6 to form an intermediate phase fluid flow channel, and the...

Embodiment 2

[0038] Example 2: Morphology Control of Conductive Fibers with Linear Core-Shell Structure

[0039] The microfluidic spinning device assembled in Example 1 was used to prepare the linear core-shell structure conductive fiber. During the preparation process, by adjusting the inner phase MXenes aqueous solution, or the intermediate phase Na-Alg / NIPAM aqueous solution, or the outer phase CaCl 2 The flow rate of the aqueous solution can observe the change of the wall thickness of the linear core-shell structure conductive fiber online, and realize the precise control of the shape of the linear core-shell structure conductive fiber, such as image 3 As shown, among them, image 3 a is external phase CaCl 2 The flow rate of the aqueous solution is fixed, and the wall thickness of the linear core-shell conductive fiber changes when the flow rate of the inner phase MXenes aqueous solution and the intermediate phase Na-Alg / NIPAM aqueous solution are adjusted; image 3 b is the flow r...

Embodiment 3

[0040] Example 3: Electrical performance test of linear core-shell conductive fiber

[0041] In Example 1 figure 2 The shown example is the linear core-shell structure conductive fiber prepared at different flow rates with MXene as the core and hydrogel as the shell. The resistance performance of the case is tested, and the corresponding resistance change value is calculated, such as Figure 4 shown;

[0042] Conductive fibers with linear core-shell structure with different core sizes are based on the same microfluidic spinning device, by adjusting the flow rate of the internal phase solution (adjusting the internal phase flow rate from 0.1 mL / h to 0.5 mL / h, maintaining the middle phase flow rate and external phase flow rates were 1.5mL / h and 10mL / h) to obtain linear core-shell conductive fibers with the same length and different inner diameters. Such as Figure 4 As shown in a, it is the relationship between the resistance of the linear core-shell structure conductive fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com