Composite binder for inorganic insulation boards and preparation method thereof

An inorganic thermal insulation board and adhesive technology, applied in the direction of inorganic adhesives, adhesives, adhesive additives, etc., can solve the problems of poor adhesion of inorganic materials, low temperature resistance of organic adhesives, poor fire resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

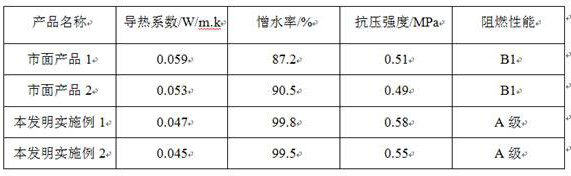

Examples

Embodiment 1

[0020] 1. Raw materials include: 12% ammonium dihydrogen phosphate, 70% magnesium oxide, 3.0% borax, 3.5% retarder, 8% silicate, 3.5% water-based additives;

[0021] 2. Phosphate preparation: add ammonium dihydrogen phosphate, magnesium oxide, borax, and retarder into the self-made reverse mixing container according to the above ratio for high-speed mixing, stirring speed 360r / min, stirring time 12min;

[0022] 3. Silicate preparation: Prepare sodium silicate, kaolin, and bentonite at a ratio of 5:3:2, and add 8% of the prepared silicate into the phosphate mixture and mix and stir for 10 minutes.

[0023] 4. Compounding of phosphate and silicate: add the prepared phosphate and silicate to the mixer in turn, the stirring speed is 450 r / min, and the stirring time is 8 minutes;

[0024] 5. Hydrophobic additive preparation: Weigh MTMS, methanol, and water in proportion, add methanol to MTMS and stir until transparent, then add water, and stir evenly.

[0025] 6. Preparation of ra...

Embodiment 2

[0028] 1. Raw material composition: ammonium dihydrogen phosphate 10%, magnesium oxide 72%, borax 3.2%, retarder 4%, silicate 7%, water-based additive 3.8%;

[0029] 2. Phosphate preparation: add ammonium dihydrogen phosphate, magnesium oxide, borax, and retarder in a certain proportion into a self-made reverse mixing container for high-speed mixing, stirring speed 380r / min, stirring time 15min;

[0030] 3. Silicate preparation: Prepare sodium silicate, kaolin, and wollastonite at a ratio of 6:2:2, and add 7% of the prepared silicate into the phosphate mixture and mix and stir for 10 minutes.

[0031] 4. Compounding of phosphate and silicate: add the prepared phosphate and silicate to the mixer in turn, the stirring speed is 450 r / min, and the stirring time is 8 minutes;

[0032] 5. Hydrophobic additive preparation: Weigh MTMS, methanol, and water in proportion, add methanol to MTMS and stir until transparent, then add water, and stir evenly.

[0033] 6. Preparation of raw ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com