High-enzyme-activity modified membrane and preparation method thereof

A high-activity, high-enzyme technology, applied in the direction of coating, etc., can solve the problems of reduced flexibility and activity, easy leakage of enzymes, poor stability, etc., to achieve high enzyme activity, prolong service life, and prolong the effect of cleaning costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0040] In this preparation example, an enzyme liquid with high enzyme activity is prepared. Steps include:

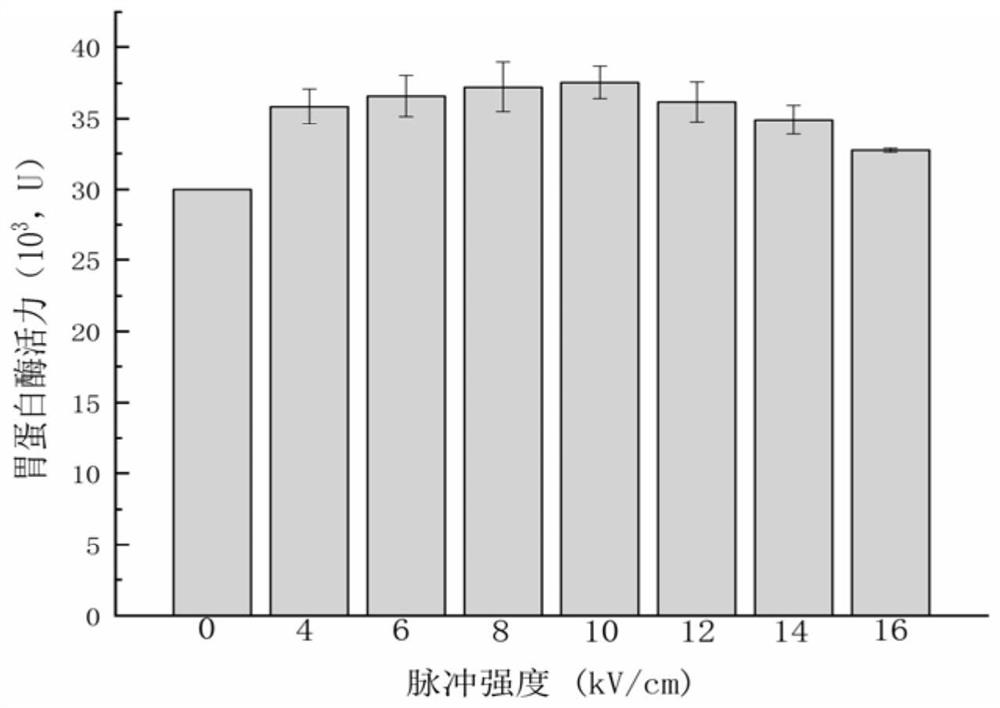

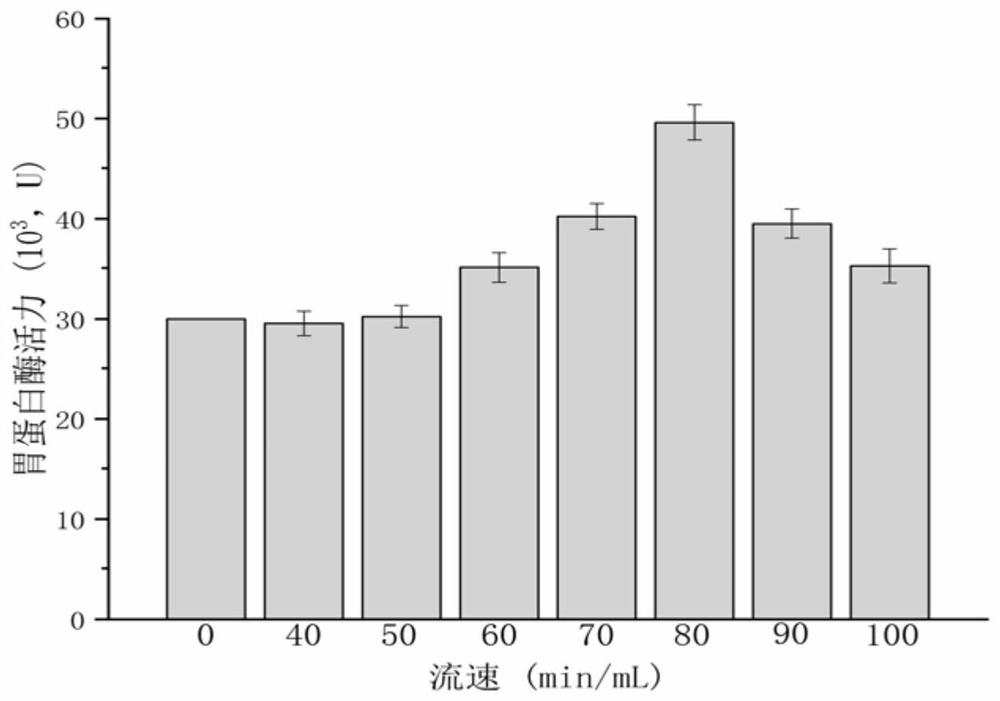

[0041] Dilute the pepsin powder with citric acid-sodium hydroxide-hydrochloric acid buffer solution with a pH=3.0 and a concentration of 0.2M to obtain a pepsin solution. After refrigerated at 4°C, it is treated with a pulsed electric field. The electric field strength is 10kV / cm, and the flow rate is 80mL·min -1 , obtain high enzyme activity enzyme liquid, the concentration of pepsin in the high enzyme activity enzyme liquid is 6mg / mL, and the pepsin enzyme activity of high enzyme activity enzyme liquid is 50 (10 3 , U).

preparation example 2

[0043] The difference from Preparation Example 1 is that the electric field strength is 0kV / cm, and the flow rate is 0mL min -1 , the enzyme activity is 30(10 3 , U).

preparation example 3

[0045] The difference from Preparation Example 1 is that the electric field strength is 4kV / cm, and the flow rate is 50mL min -1 , the enzyme activity is 35.5 (10 3 , U).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com