Preparation method of ordered mesoporous silicon-carbon composite material

A carbon composite material, mesoporous silicon technology, applied in the preparation/purification of carbon, silicon compounds, chemical instruments and methods, etc., can solve the problems of large volume expansion, poor material performance, and difficulty in commercialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

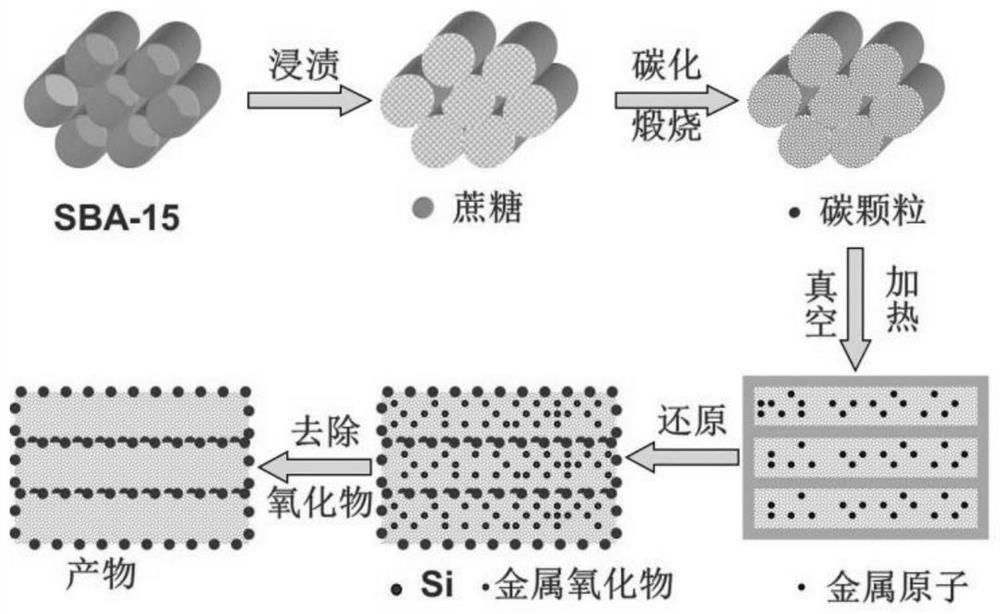

[0038] Such as figure 1 and figure 2 As shown, a method for preparing an ordered mesoporous silicon-carbon composite material comprises the following steps:

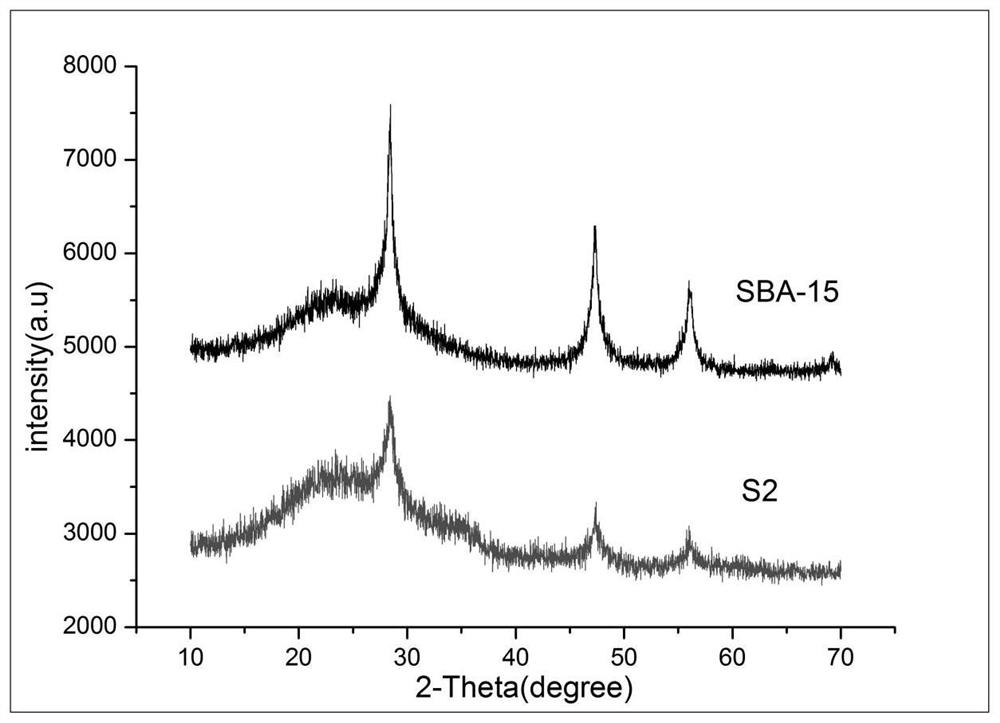

[0039] (I) Preparation of ordered mesoporous molecular sieve (SBA-15): Dissolve 2.5g of structure-directing agent in deionized water, add 12mL of concentrated hydrochloric acid (36%), stir for 1.5h, and then add 5.4mL of silicon source dropwise , stirring rapidly for 8 minutes. Transfer it to a reaction kettle, heat at 40°C for 24 hours, heat at 100°C for 48 hours, filter, wash the resulting product repeatedly with deionized water, put it into a tube furnace, and heat up at a rate of 2°C / min Calcined at 500° C. for 10 hours to obtain ordered mesoporous molecular sieve (SBA-15) with stripped template.

[0040] Wherein, the structure directing agent is triblock copolymer polyethylene oxide-polypropylene oxide-polyethylene oxide (PEO-PPO-PEO), cetyl ammonium bromide and sodium lauroyl glutamate.

[0041] Wherein, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com