Cylindrical grinding machine hook gauge

A cylindrical grinding machine and casing technology, which is applied in the directions of grinding machines, grinding machine parts, and machine tools designed for grinding the rotating surface of workpieces, etc. , the positioning is flexible and accurate, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

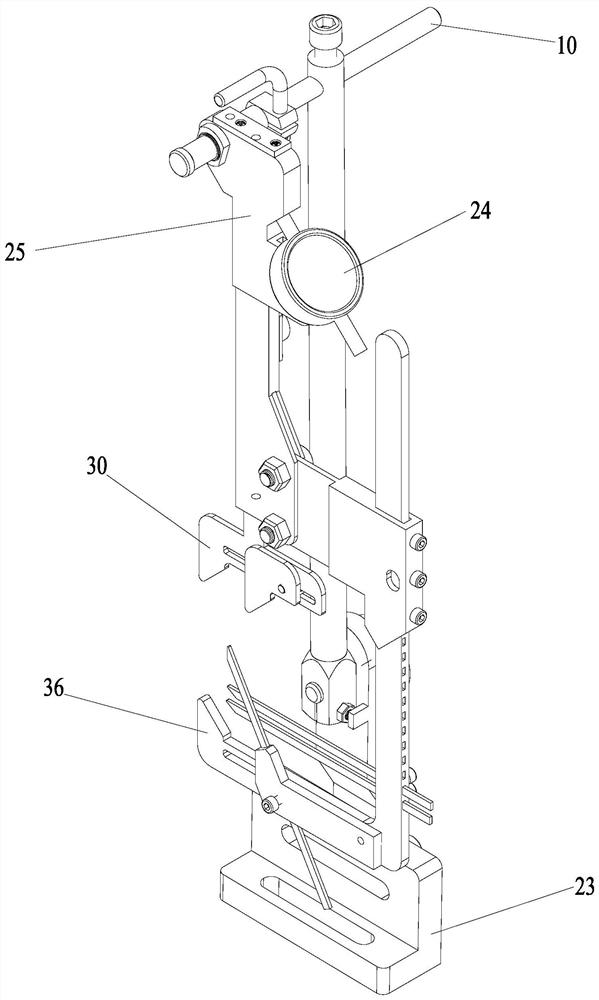

[0027] Figure 1~12 Among them, including pin cap 1, upper ejector pin washer 2, hexagon socket head cap screw 3, upper ejector pin 4, first screw nut 5, first screw 6, second screw nut 7, second screw 8, third Screw 9, support rod 10, first nut 11, sleeve 12, support lever 13, eccentric clip 14, second nut 15, fourth screw 16, lever 17, coil spring assembly 18, third screw nut 19, coil spring connection Rod 20, connecting plate 21, fourth screw nut 22, fixed angle iron 23, dial indicator 24, hook meter body 25, upper cover plate 26, fifth screw 27, first spring 28, upper ejector rod 29, hook rod Seat 30, second spring 31, lower ejector rod 32, ejector rod slider 33, hook bar slide needle 34, hook bar slider 35, hook bar 36, coil spring rotating disk 37, coil spring shell 38, coil spring 39, Sixth screw 40 and so on.

[0028] Such as Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com