Sealing position abrasion repairing method for high-end equipment remanufacturing

A wear repair and remanufacturing technology, which is applied in the field of seal wear repair for high-end equipment remanufacturing, can solve problems such as high wear rate, abnormal size of seals, and performance degradation, so as to reduce errors, ensure performance, and prevent malfunctions The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

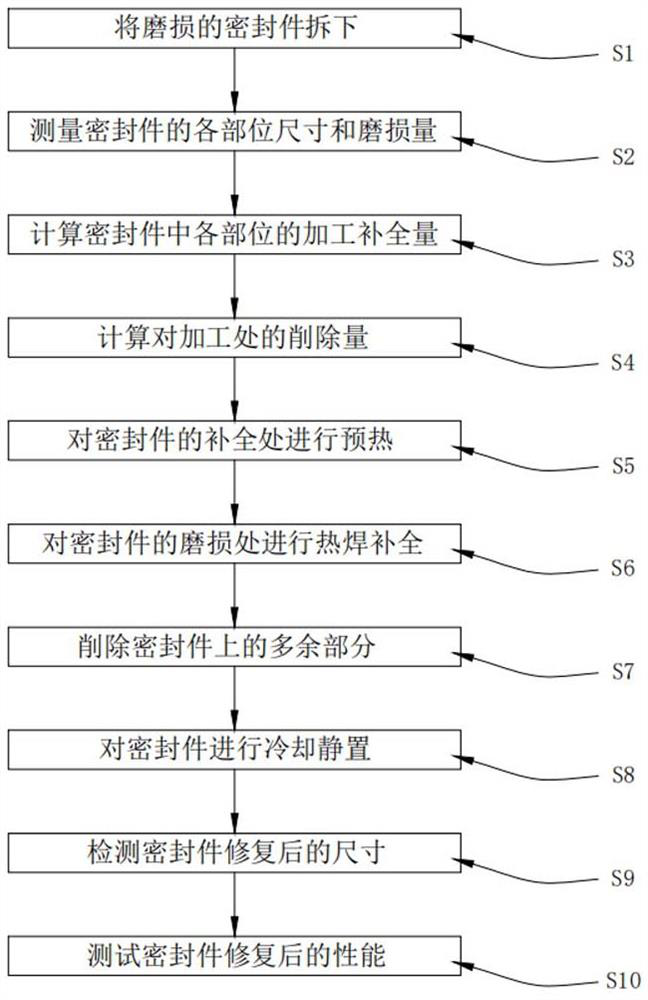

[0032] see figure 1 , the present invention provides a technical solution: a method for repairing wear and tear of seals for high-end equipment remanufacturing, comprising the following steps:

[0033] S1. Remove the worn seal, place the removed seal on a flat horizontal workbench, align the seal on the workbench to form a circle, and fix it on the workbench;

[0034] S2. Measure the size and wear amount of each part of the seal, respectively measure the overall size and wear amount of the seal, and compare the measured data with the production data of the seal. The measurement error is within 0.1mm as qualified;

[0035] S3. Calculating the processing complement amount of each part of the seal, calculating the processing complement amount of each part of the seal according to the measurement results of the seal and the production data of the seal, and comparing the calculation result with the wear amount;

[0036] S4. Calculate the removal amount of the processed part, and c...

Embodiment 2

[0051] see figure 1 , the present invention also provides a technical solution, which is different from Embodiment 1 in that: a method for repairing seal wear for high-end equipment remanufacturing, comprising the following steps:

[0052] S1. Remove the worn seal, place the removed seal on a flat horizontal workbench, align the seal on the workbench to form a circle, and fix it on the workbench;

[0053]S2. Measure the size and wear amount of each part of the seal, respectively measure the overall size and wear amount of the seal, and compare the measured data with the production data of the seal. The measurement error is within 0.1mm as qualified;

[0054] S3. Calculating the processing complement amount of each part of the seal, calculating the processing complement amount of each part of the seal according to the measurement results of the seal and the production data of the seal, and comparing the calculation result with the wear amount;

[0055] S4. Calculate the remova...

Embodiment 3

[0070] see figure 1 , the present invention also provides a technical solution, which is different from Embodiment 1 in that: a method for repairing seal wear for high-end equipment remanufacturing, comprising the following steps:

[0071] S1. Remove the worn seal, place the removed seal on a flat horizontal workbench, align the seal on the workbench to form a circle, and fix it on the workbench;

[0072] S2. Measure the size and wear amount of each part of the seal, respectively measure the overall size and wear amount of the seal, and compare the measured data with the production data of the seal. The measurement error is within 0.1mm as qualified;

[0073] S3. Calculating the processing complement amount of each part of the seal, calculating the processing complement amount of each part of the seal according to the measurement results of the seal and the production data of the seal, and comparing the calculation result with the wear amount;

[0074] S4. Calculate the remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com