Welding production line and welding method of truss intersecting line

A welding production line and welding method technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high dependence on manpower, difficulty in improving efficiency, and difficulty in automatic welding equipment welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

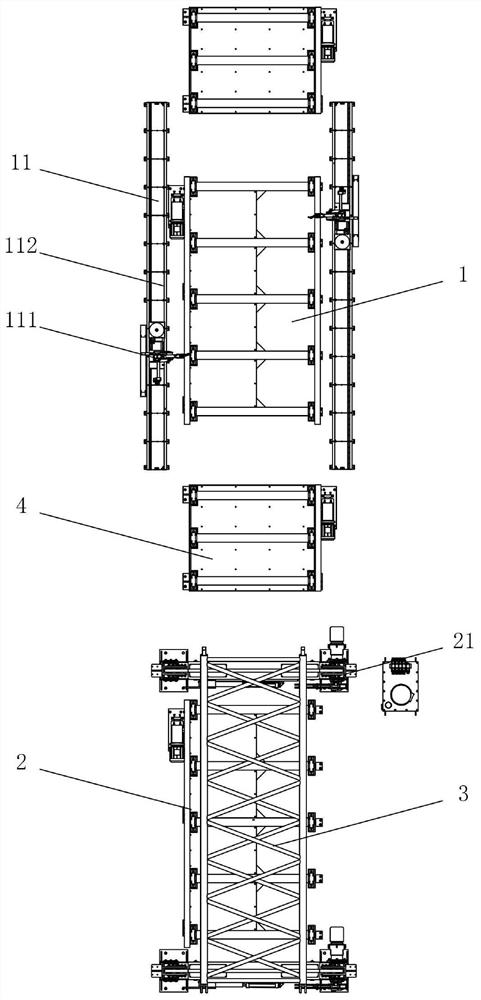

[0041] Such as figure 1 As shown, the truss intersecting line welding production line of this embodiment includes a welding station 1 and an overturning station 2. The overturning station 2 is provided with an overturning device 21 for overturning the truss 3. The overturning device 21 can make the truss 3 wind around itself The axis of the truss is overturned, and a conveying device 4 for transporting the truss 3 is provided between the overturning station 2 and the welding station 1. During welding production, the welding station 1 welds the intersecting line on the bottom side of the current vertical side of the truss 3. After the welding is completed, the conveying device 4 transports the truss 3 to the turning station 2, and the turning station 2 The flipping device 21 flips the truss 3, so that the side of the truss is changed, and the side that is originally adjacent to the vertical side is flipped to a vertical position, so that the unwelded intersecting line is expose...

Embodiment 2

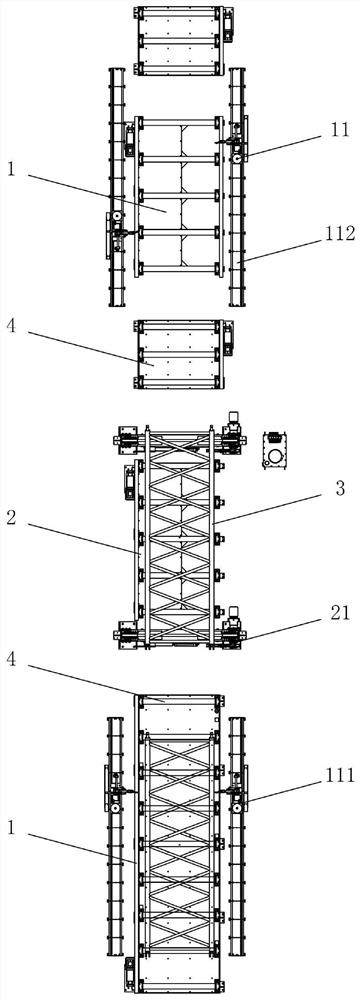

[0054] Such as figure 2 As shown, this embodiment is basically the same as Embodiment 1, the difference is that in this embodiment, there are two welding stations 1, and a turning station 2 is provided between two adjacent welding stations 1 . During welding production, the two welding stations 1 can deliver the welded truss 3 to the flipping station 2 four times through the conveying device, or receive the flipped truss 3 from the flipping station 2. The setting method of this production line is similar. Compared with the one-to-one arrangement of welding station 1 and turning station 2, the waiting time of turning station 2 can be used to turn over the truss 3 that has been welded in another welding station 1, shortening the time required for turning over. The waiting time of station 2 improves the utilization rate of stations and further optimizes the production mode of the production line.

[0055] Correspondingly, in the welding method of welding truss intersecting line...

Embodiment 3

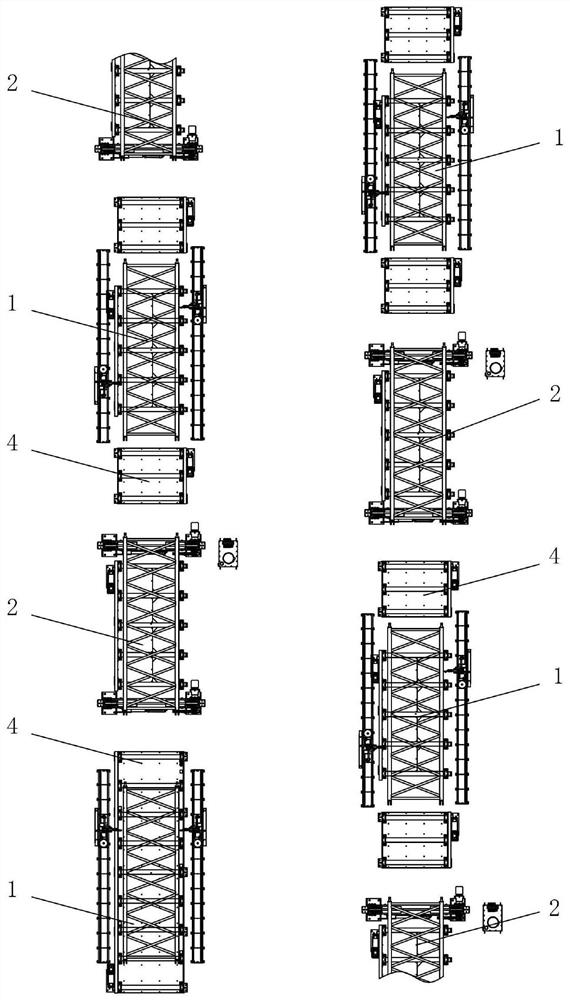

[0064] Such as image 3 As shown, this embodiment is basically the same as Embodiment 1, the difference is that in this embodiment, there are four welding stations 1, three turning stations 2, and three turning stations 2 are respectively arranged in each Between two adjacent welding stations 1. During welding production, the truss 3 passes through the welding station 1, the turning station 2, the welding station 1, etc. in sequence along the production direction of the production line, until four times of welding and three times of turning are completed alternately. Compared with In embodiment 1, the interval time of putting into the truss 3 to be welded is only the time of the intersecting line on one side of the welding truss 3, which can realize a one-way production line, which is more in line with the production standard of the line type, further Increased production efficiency.

[0065] Correspondingly, the welding method for welding truss intersecting lines using the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com