a solid co 2 Particle jet cleaning device

A cleaning device, CO2 technology, applied in cleaning methods and utensils, grain processing, chemical instruments and methods, etc., can solve the problems of uneven mixing of dry ice and conveying gas, uneven dry ice particles, and different sizes of dry ice particles, etc., to achieve Better cleaning effect, improved dry ice cleaning effect, and high uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

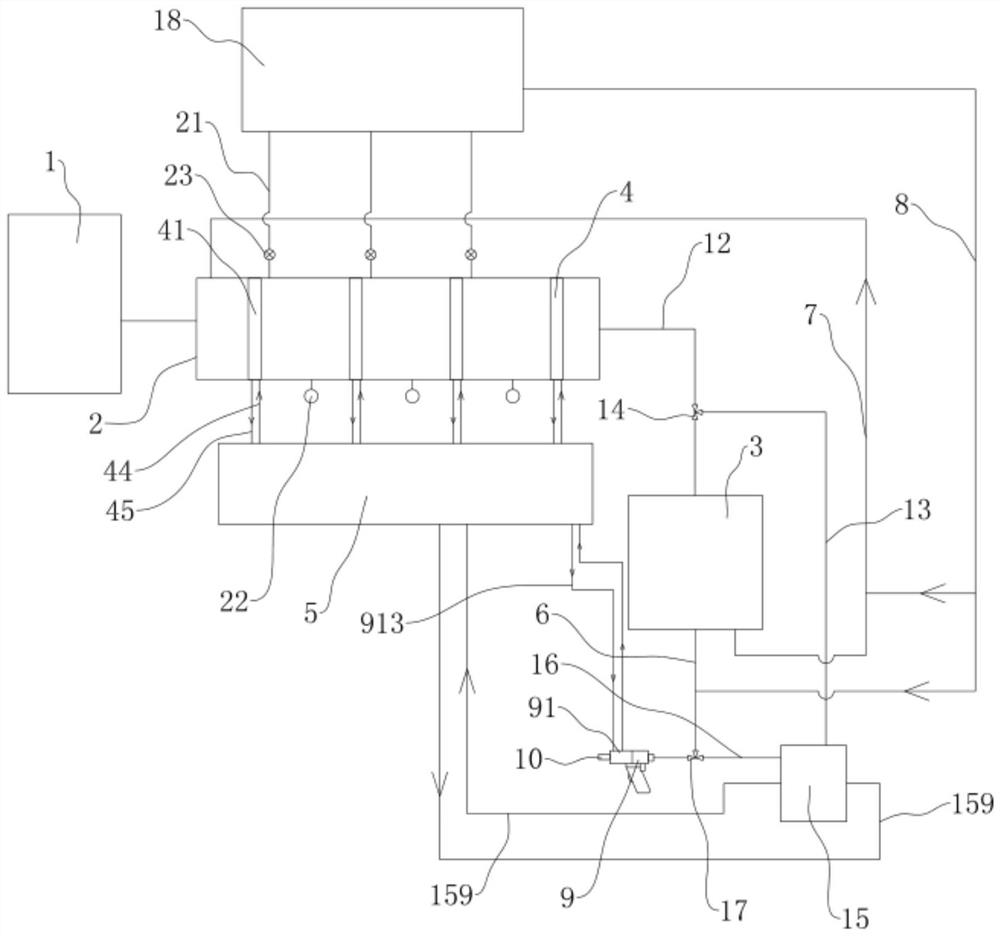

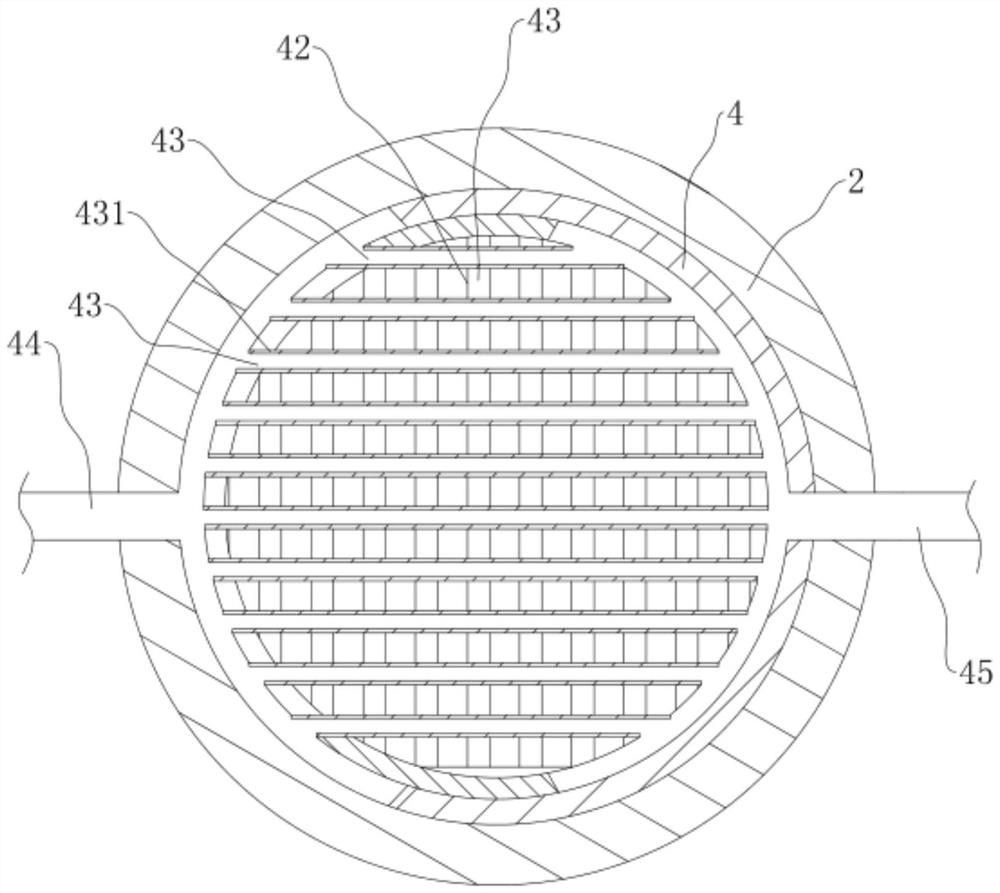

[0032] refer to Figure 1 to Figure 6 For solid CO 2 The particle jet cleaning device is further described.

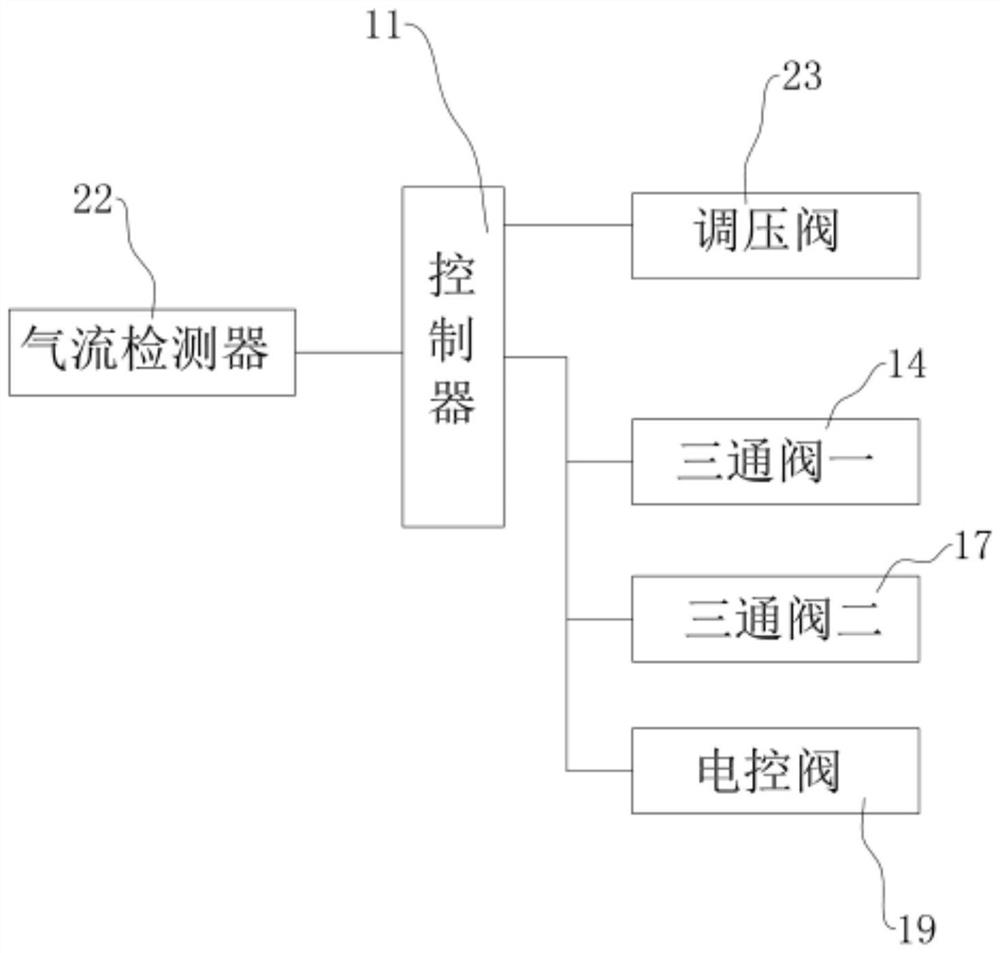

[0033] a solid CO 2 Particle jet cleaning devices, such as figure 1As shown, it includes a dry ice granulation mechanism 1, a dry ice collision channel 2, and a centrifugal separator 3 connected in sequence. The centrifugal separator 3 is used to centrifugally separate the collided dry ice into dry ice particles and dry ice particles. 3 is connected with a dry ice particle pipe 6 for dry ice particle transportation and a dry ice particle recovery pipe 7 for dry ice particle transportation. The discharge end of the dry ice particle recovery pipe 7 is connected to the dry ice collision channel 2 for cyclic collision. The discharge end is connected with a dry ice cleaning spray gun 9, and the discharge end of the dry ice cleaning spray gun 9 is connected with a nozzle 10. The dry ice particles of different sizes after collision are separated from the dry ice particles ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com