Shockproof mechanism of laser cleaning machine

A laser cleaning and laser technology, applied in mechanical equipment, springs/shock absorbers, cleaning methods and appliances, etc., can solve problems affecting the normal output of laser beams, insufficient stability of laser beam output, vibration and shaking of internal components, etc., to achieve improved Anti-shock effect, reduce machine shaking, and improve the effect of cushioning force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

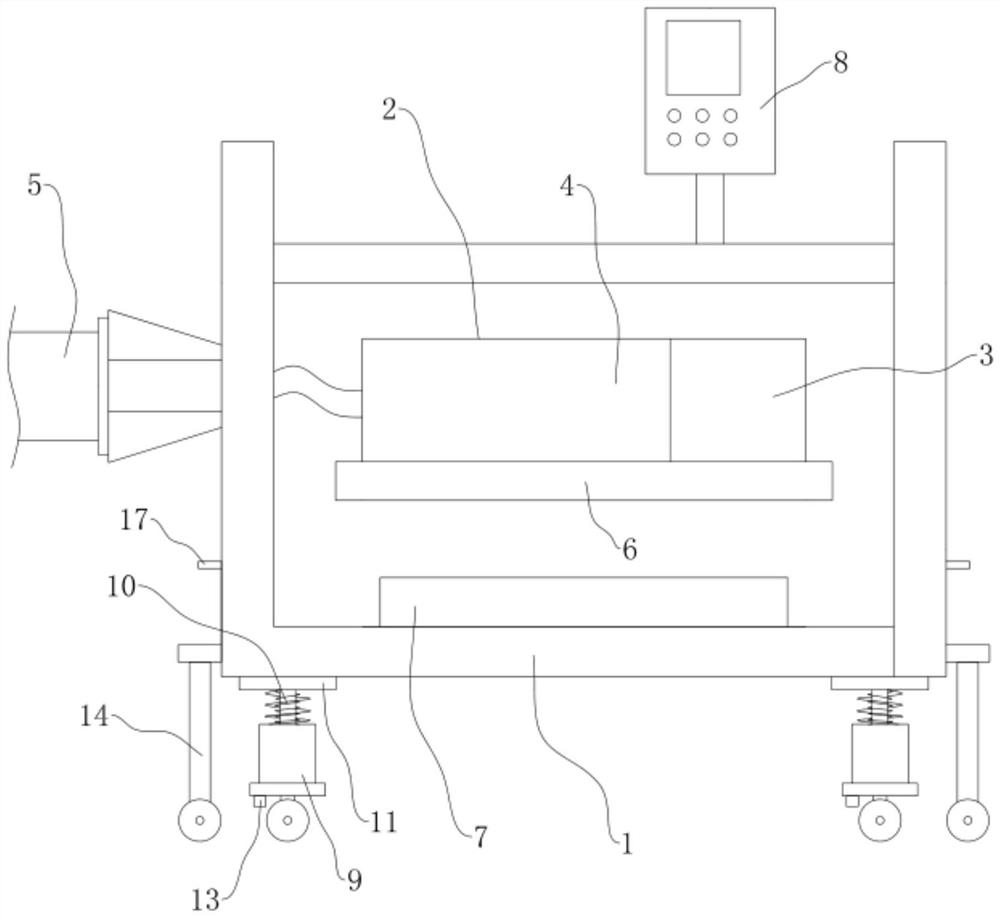

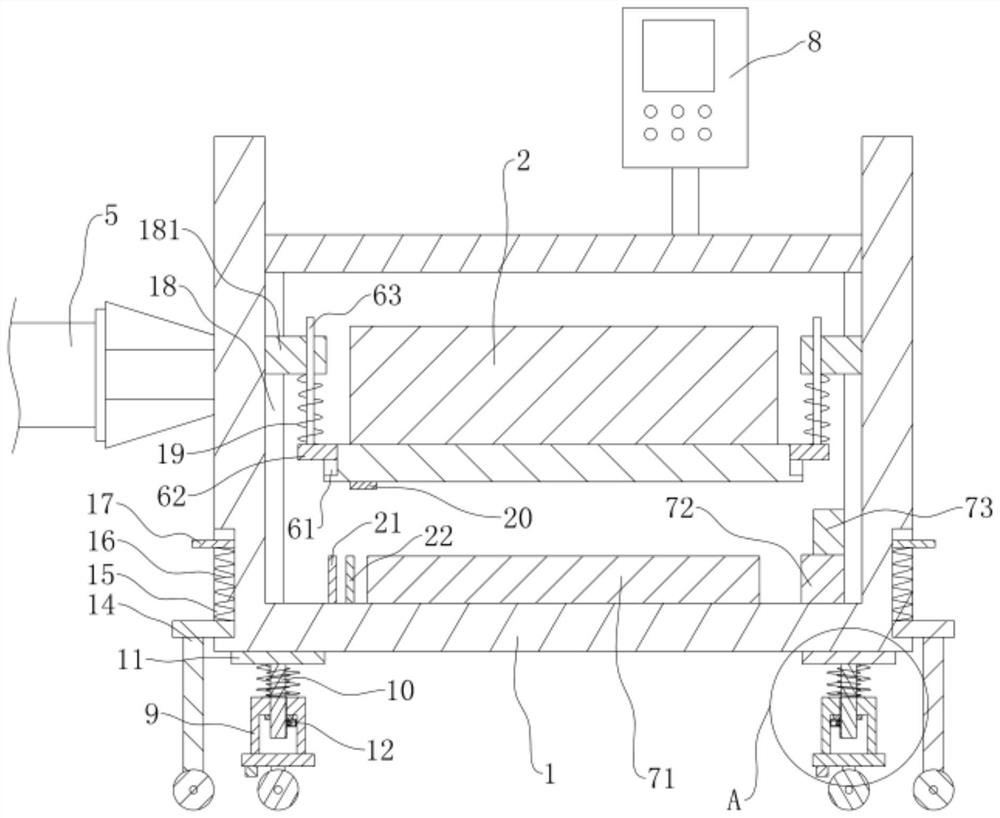

[0027] refer to Figure 1 to Figure 3 Further explain the anti-shock mechanism of the laser cleaning machine.

[0028] A shockproof mechanism of a laser cleaning machine, such as figure 1 As shown, it includes a machine 1 and a laser host 2 arranged on the machine 1. The machine 1 and the laser host 2 are installed in a closed casing, and the laser host 2 is provided with a laser generator 3 capable of generating laser beams and related hosts. 4. At least one laser external pipeline 5 is provided on the side wall of the machine 1 to generate laser for use by the cleaning machine.

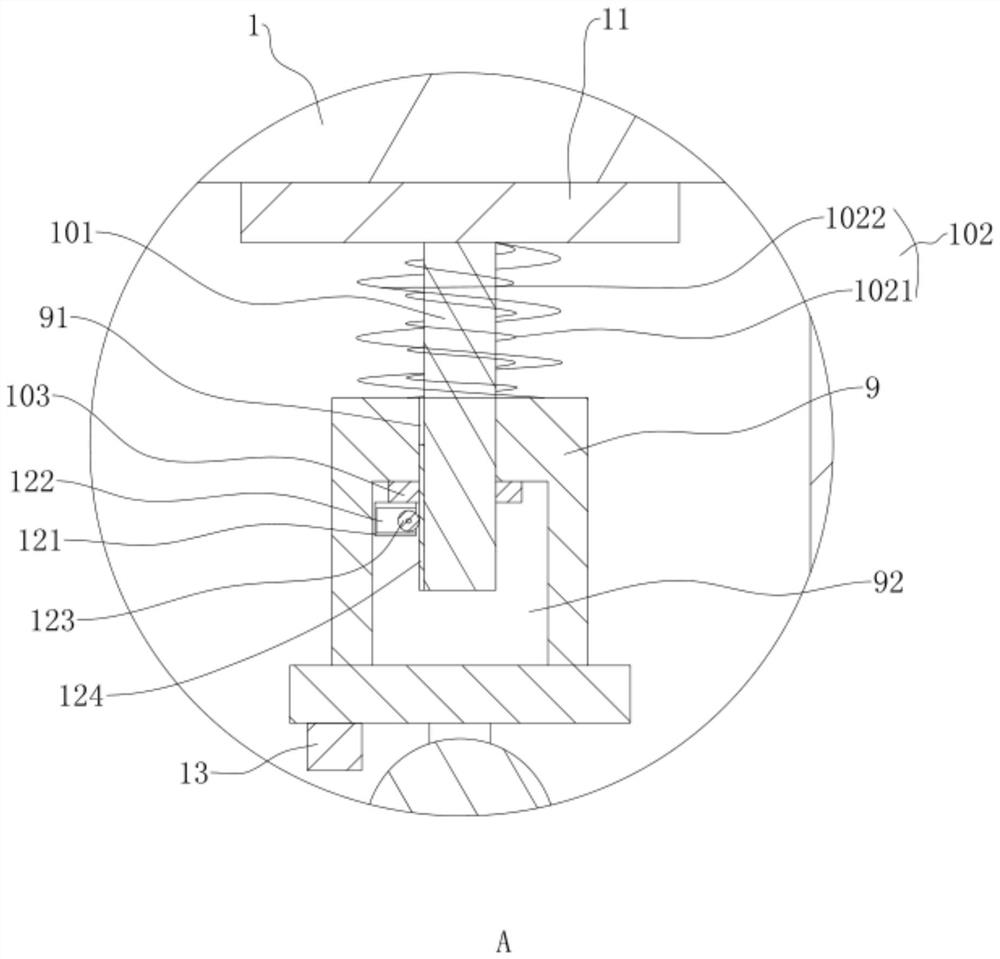

[0029] like figure 1 and figure 2 As shown, a support seat 9 is provided at the bottom of the machine platform 1, and a buffer member 10 for providing a buffer force is provided between the support seat 9 and the machine platform 1. One end of the buffer member 10 is connected to the support seat 9, and the other end is connected to a The support piece 11 is in contact with the bottom of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com