Power cable recycling and cleaning device

A cleaning device and power cable technology, applied in the direction of electronic waste recycling, recycling technology, circuits, etc., can solve the problems of poor cleaning effect, low cleaning efficiency, and increased equipment production costs, and achieve reasonable structure, good effect, and reduced Effect of replacement cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

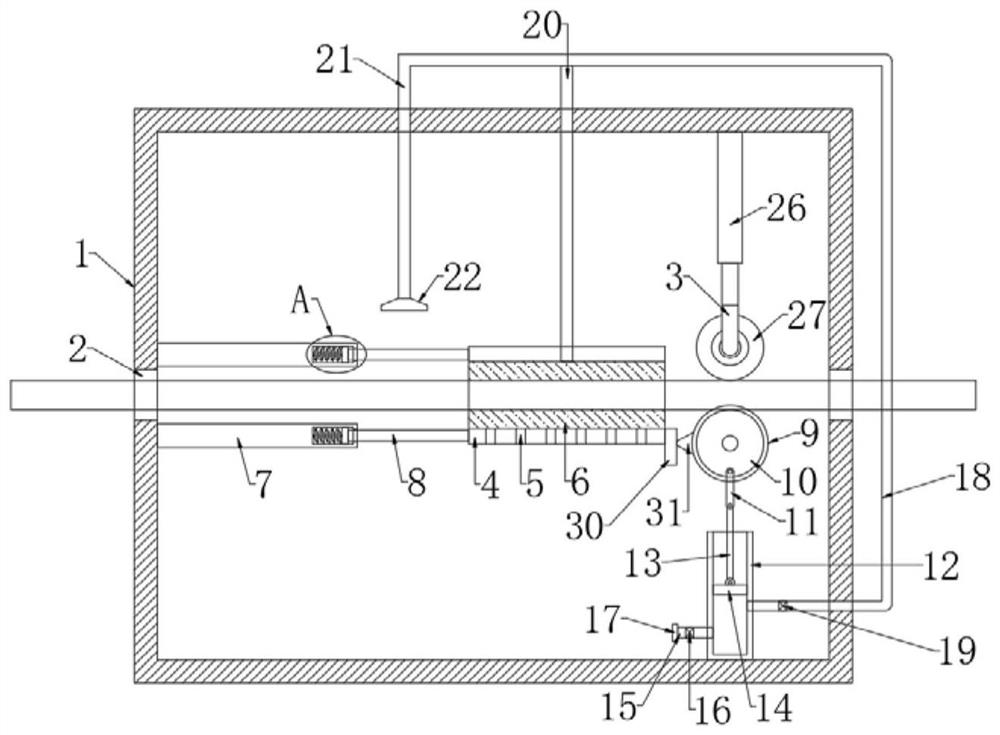

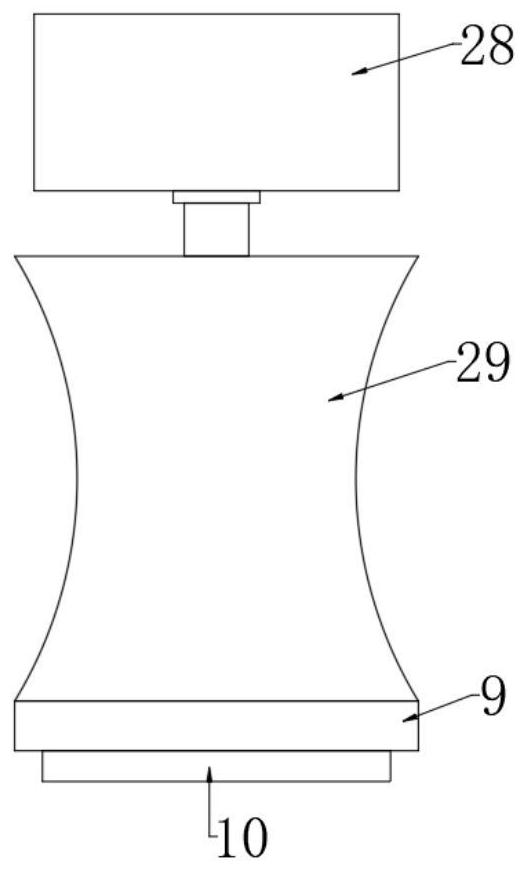

[0027] refer to Figure 1-3 , a power cable recycling cleaning device, including a cleaning box 1, the cleaning box 1 is filled with an appropriate amount of water; both ends of the cleaning box 1 are provided with conveying holes 2 to facilitate the passage of cables; the cleaning box 1 is provided with a round The central axis of the tube 4 and the circular tube 4 are on the same axis as the transverse axes of the two conveying holes 2, so that the cables pass through the circular tube 4 conveniently, and then the cables are conveniently installed.

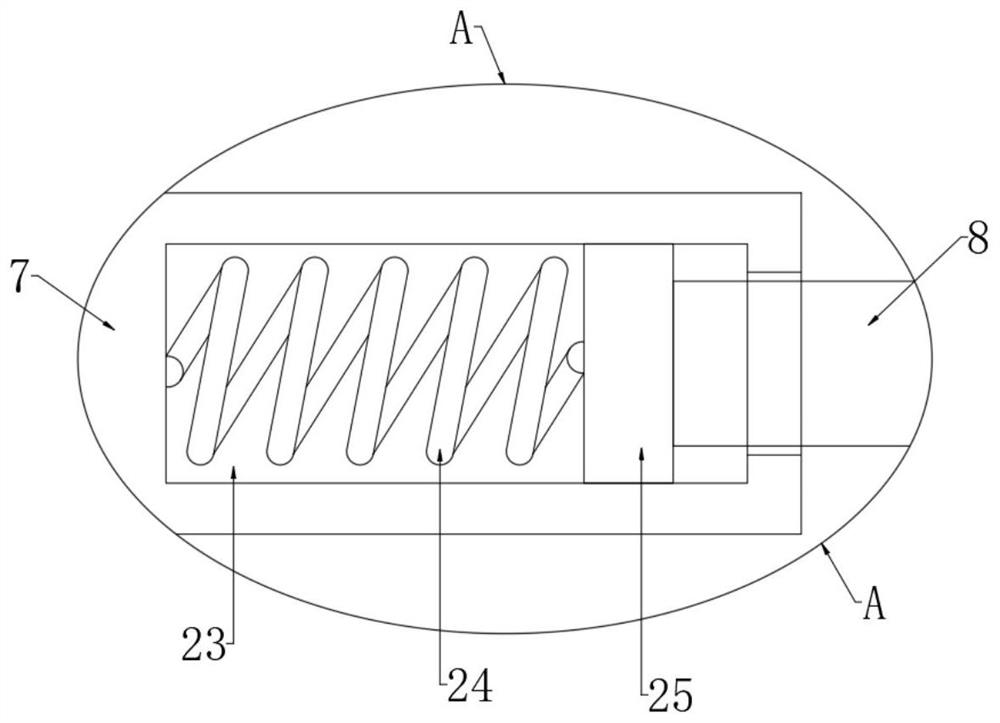

[0028] Cleaning cotton 6 is installed in the round pipe 4, and a plurality of water leakage holes 5 are provided through the bottom of the round pipe 4 to facilitate the discharge of clear water; the round pipe 4 is connected with the inner wall of the cleaning box 1 through two reset supports, and the reset supports include The first crossbar 7 fixed on the inner wall of the cleaning box 1 is provided with a hollow cavity 23 in...

Embodiment 2

[0037] refer to Figure 4-5 The difference between this embodiment and Embodiment 1 is that in this embodiment, the opposite sides of the two second crossbars 8 are fixedly connected with a brush 32, and the side of the brush 32 close to the cable can be set as an arc that matches the cable. , two brushes 32 are arranged oppositely; the circular tube 4 is fixedly connected with a ring 33, the inner wall of the ring 33 is equipped with a sponge 34, and the inner wall of the cleaning box 1 is equipped with a top-shaped hollow tube 35, Described hollow cylinder 35 is matched with sponge 34, and the two ends of described hollow cylinder 35 are all equipped with annular baffle; Wherein hollow cylinder 35 and circular ring 33 coincide with the axis of round pipe 4; Wherein the front and rear ends of hollow cylinder 35 are fixed If the support rod is connected, the support rod is fixedly connected with the inner wall of the cleaning box 1 .

[0038] In this embodiment, the brush 32 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com