Preparation method of graphene antibacterial composite film, prepared antibacterial composite film

A graphene and composite membrane technology, applied in the field of composite materials, can solve the problems of environmental hazards, dangerous chemical reagents, high toxicity, etc., and achieve the effects of short time consumption, simple reaction and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The preparation of graphene antibacterial composite film comprises the following steps:

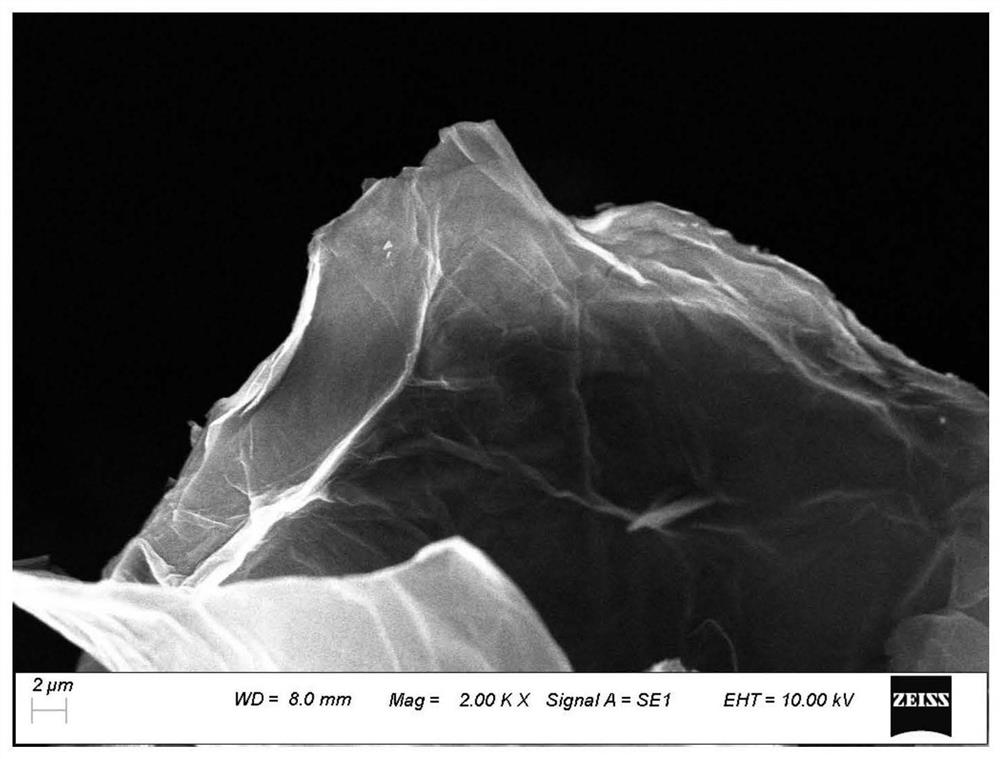

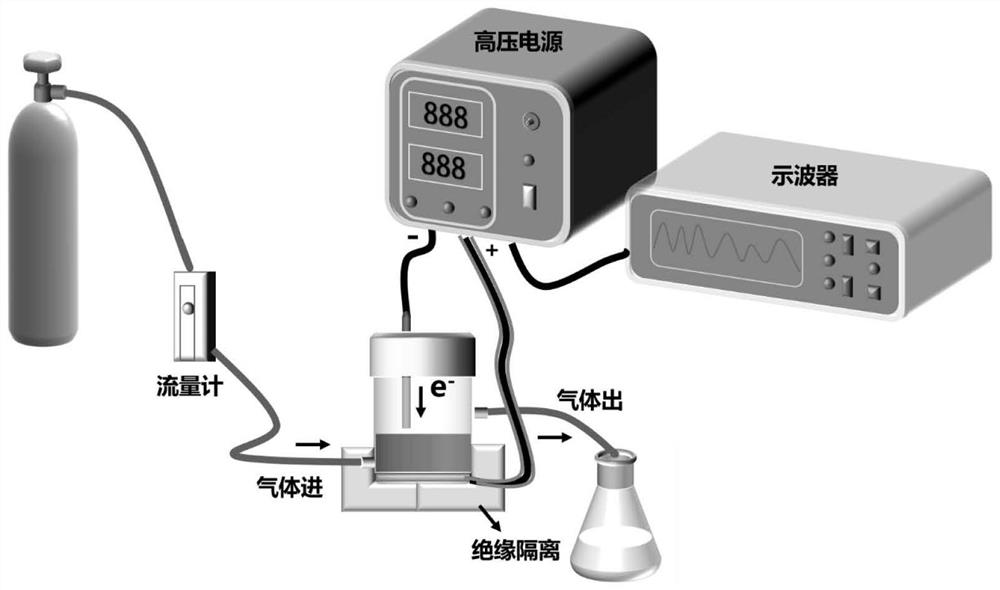

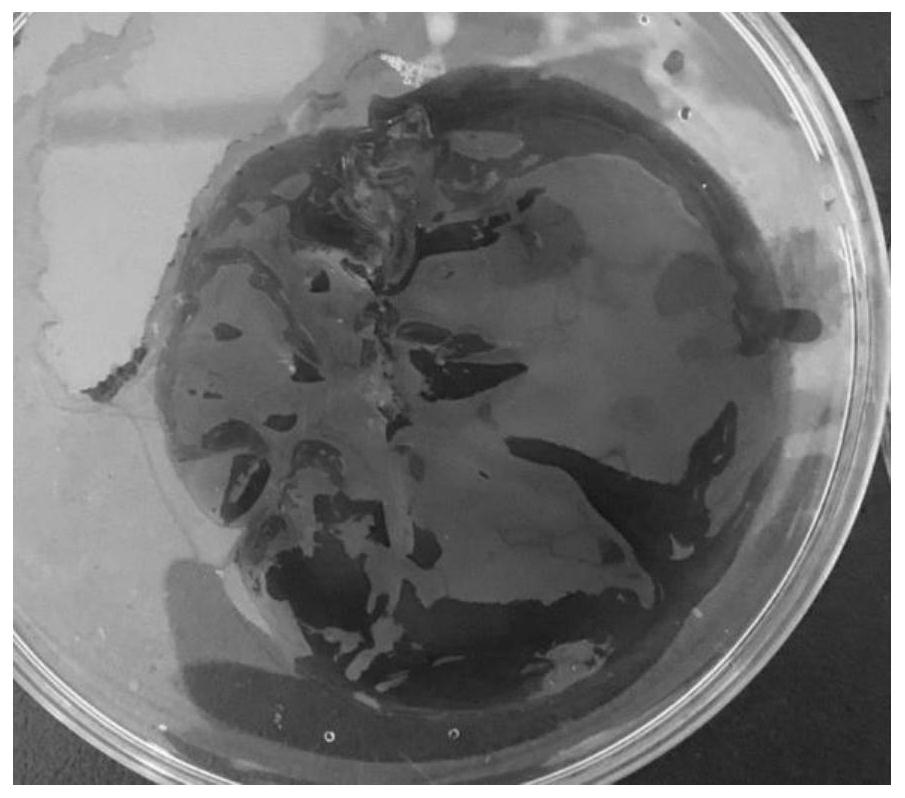

[0044] (1) Preparation of graphene oxide aqueous solution: put into about 40ml concentrated sulfuric acid (98%) in flask, 1g flake graphite is first stirred at room temperature for one hour and it is fully mixed, then the mixture is placed in an ice bath, Slowly add 3g of potassium permanganate and react for 1h. Then the reaction system was transferred to an oil bath and reacted at 45° C. for 1 h. The temperature was raised to 85°C, and 85ml of water was slowly added dropwise, and then about 30ml of hydrogen peroxide was added, and the stirring was continued until no obvious bubbles were generated, and the reaction was completed. The product was washed with 5% hydrochloric acid and filtered, and finally purified by dialysis with a dialysis bag, and then freeze-dried at -50°C for 12 hours. The solid product was dispersed in water and ultrasonicated at 40KW for 2 hours to obtain a f...

Embodiment 2

[0055] The preparation of graphene antibacterial composite film comprises the following steps:

[0056] (1) Preparation of graphene oxide aqueous solution: put about 80ml of concentrated sulfuric acid (98%) in the flask, stir 2g flake graphite at room temperature for 1h to make it fully mixed, then place the mixture in an ice bath, slowly add 6g potassium permanganate, react for 1h. Then the reaction system was transferred to an oil bath and reacted at 45° C. for 1 h. The temperature was raised to 85°C, and 85ml of water was slowly added dropwise, and then about 40ml of hydrogen peroxide was added, and the stirring was continued until no obvious bubbles were generated, and the reaction was completed. The product was washed with 5% hydrochloric acid and filtered, and finally purified by dialysis with a dialysis bag, and then freeze-dried at -50°C for 12 hours. The solid product was dispersed in water and ultrasonicated at 40KW for 2 hours to obtain a final concentration of abo...

Embodiment 3

[0063] The preparation of graphene antibacterial composite film comprises the following steps:

[0064] (1) Preparation of graphene oxide aqueous solution: put about 60ml of concentrated sulfuric acid (98%) in the flask, stir 1.5g flake graphite at room temperature for one hour and make it fully mixed, then place the mixture in an ice bath , Slowly add 4.5g potassium permanganate, react for 1h. Then the reaction system was transferred to an oil bath and reacted at 45° C. for 1 h. The temperature was raised to 85°C, and 85ml of water was slowly added dropwise, and then about 35ml of hydrogen peroxide was added, and the stirring was continued until no obvious bubbles were generated, and the reaction was completed. The product was washed with 5% hydrochloric acid and filtered, and finally purified by dialysis with a dialysis bag, and then freeze-dried at -50°C for 12 hours. The solid product was dispersed in water and ultrasonicated at 40KW for 2 hours to obtain a final concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com