Loudspeaker box and its assembly process

A loudspeaker box, sound guide technology, applied in the direction of sensor, single transducer combination, transducer shell/cabinet/stand, etc. Increased volume, improved acoustic performance, simple and efficient assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

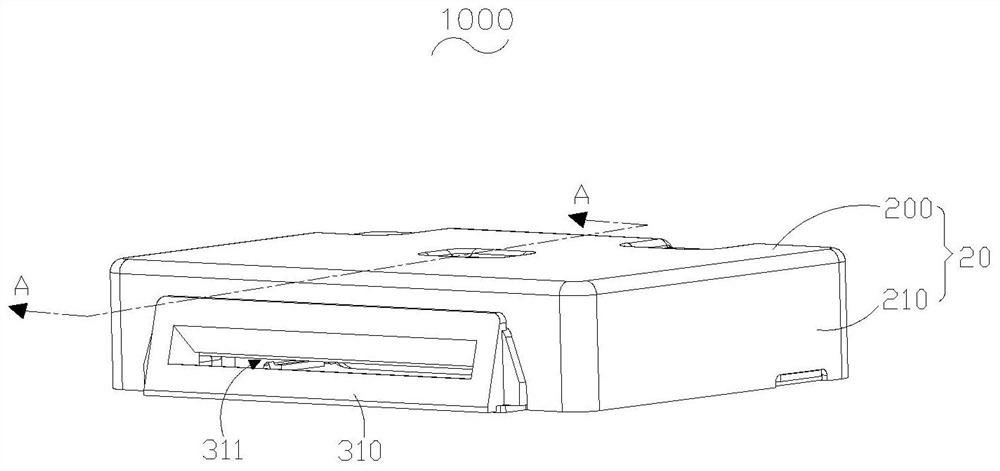

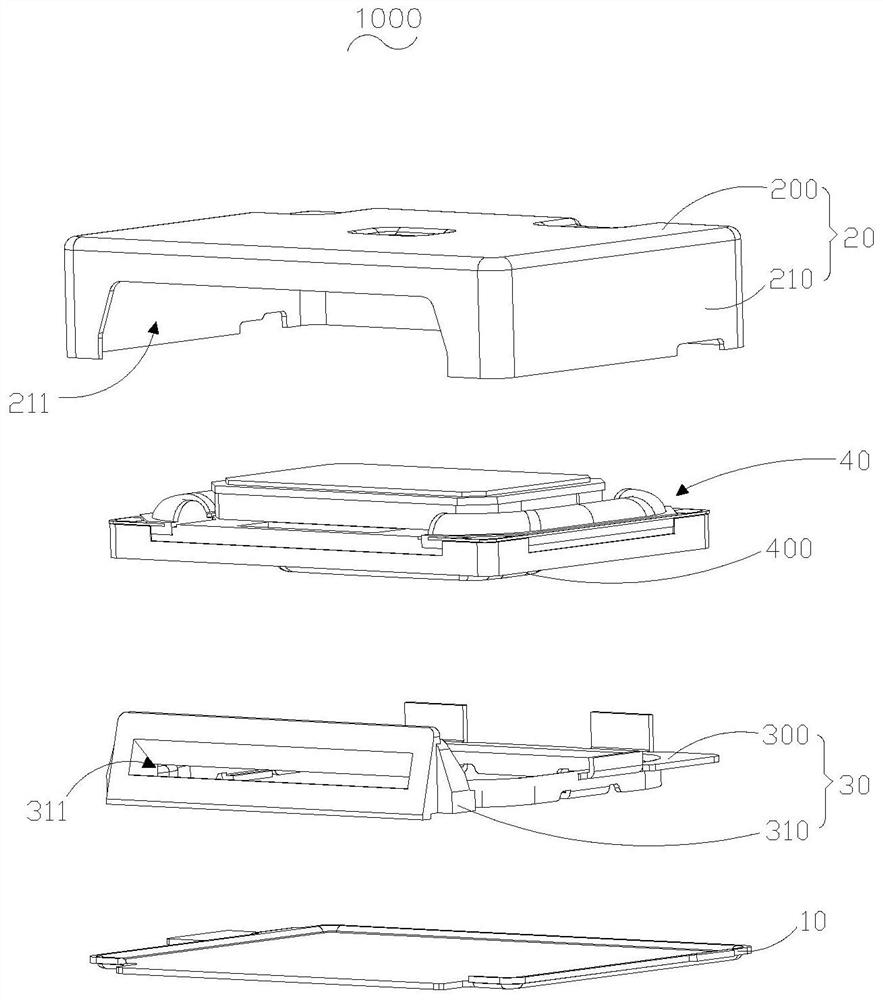

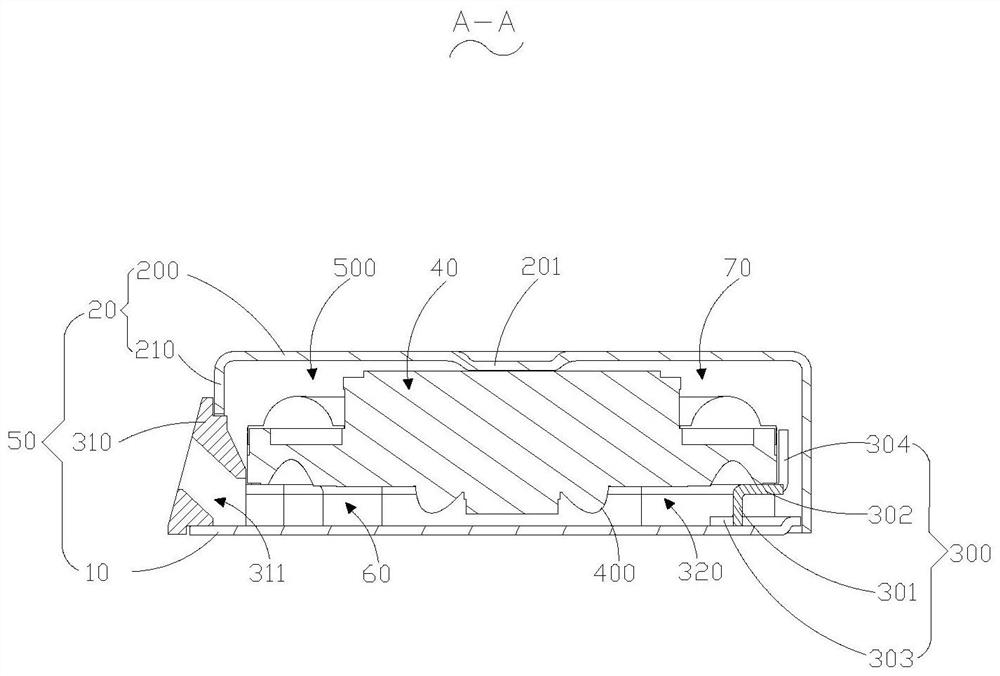

[0028] Please also see Figure 1-4 As shown, the present invention provides a speaker box 1000, which includes a sounding unit 40 with a diaphragm 400 for vibrating and sounding, a front cover 10 made of a metal material, and an integral injection molding fixedly supported on the front cover 10. The bracket 30 and the rear cover 20 made of metal material are covered on the front cover 10 and the bracket 30 .

[0029] The bracket 30 includes a support body 300 supporting the sounding unit 40 and an outer connection body 310 connected to the support body 300 and enclosing a ring-shaped through hole 320. The ring-mounted through hole 320 extends along the vibration direction of the diaphragm 400 and accommodates the vibration. The membrane 400 and the outer connecting body 310 are provided with a sound guiding channel 311 running through it.

[0030] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com