Prime mover, acting method and hydraulic turbine set

A technology of prime mover and water turbine, applied in the field of prime mover, can solve the problems of large kinetic energy or electric energy consumption, long refrigerant flow path, and inability to generate economic benefits, and achieve the effects of large output force, low cost, and reduced manufacturing difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The following detailed description will set forth the general principles of the invention, examples of which are additionally illustrated in the accompanying drawings. In the drawings, like reference numbers indicate identical or functionally similar elements. As used herein, the term energy fluid may include any liquid.

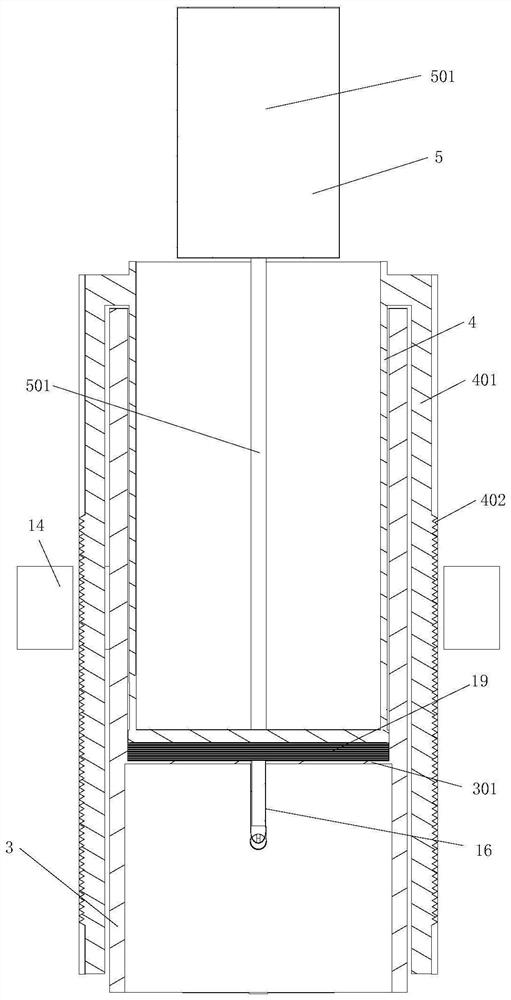

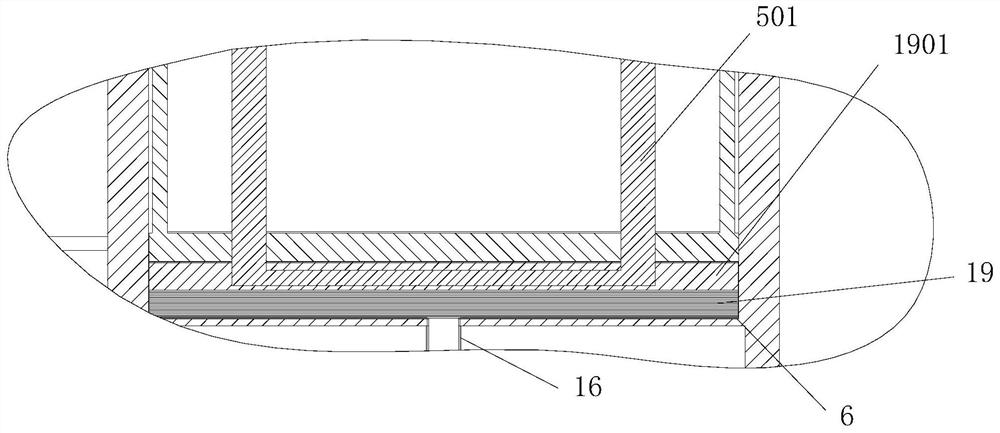

[0072] Such as Figure 1-4 As shown, the present invention includes an evaporator 2, a body 3 and an energy body 4, the energy body 4 is slidably arranged in the body 3, a cavity 6 is formed between the bottom of the energy body 4 and the inner wall of the body 3, and the cavity 6 is provided with Inner tank 19, the inner tank 19 is a stretchable structure, such as an air bag, the evaporated liquid working medium is transported into the inner tank 19, the inner volume of the inner tank 19 expands, and the working stroke is carried out along the cavity 6; during the liquefaction process, the energy body 4. The inner tank 19 shrinks due to its own wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com