Composite floor truss and bottom bar arrangement method

A technology of superimposing floor slabs and trusses, which is applied to floors, buildings, building reinforcements, etc., can solve problems such as troublesome operation, low replacement rate of trusses, and irregular layout of bottom bars, so as to save production costs, reduce steel content, The effect of improving design efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with drawings and embodiments. The terms "first", "second", "third", etc. are used for descriptive purposes only and should not be construed as indicating or implying relative importance.

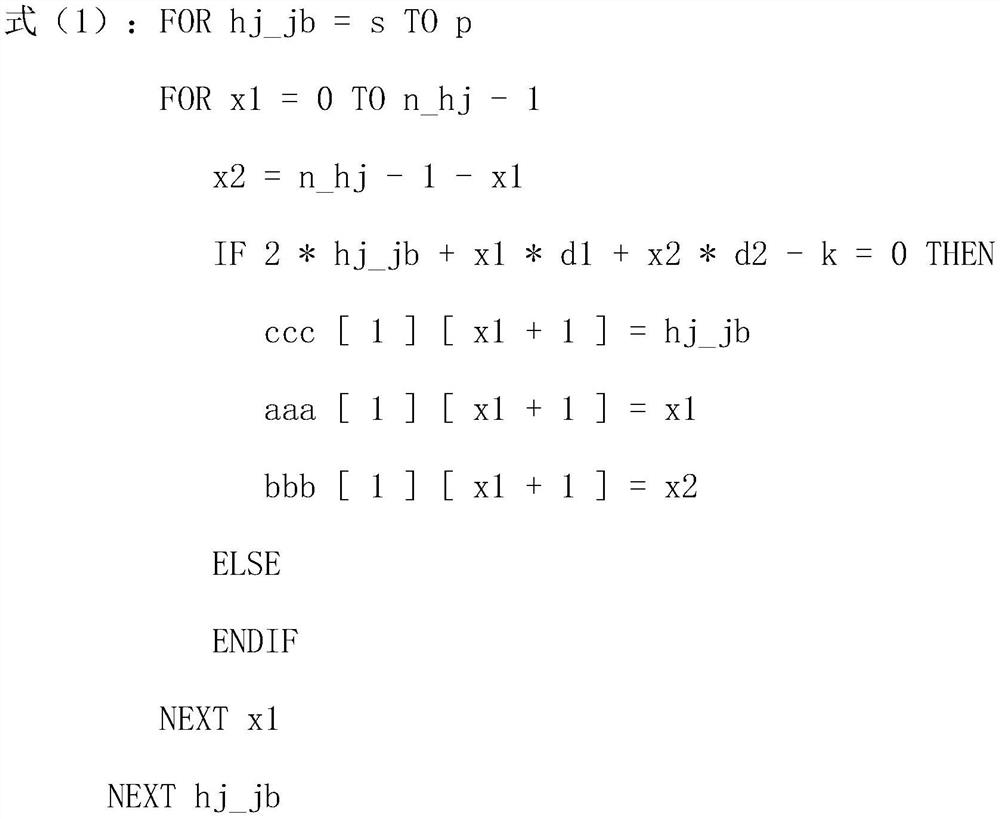

[0051] Such as figure 1 As shown, a laminated floor truss arrangement method, including

[0052] Step S1: Calculate the number of trusses required. In this application, calculate by formula (4):

[0053] Formula (4):

[0054] n_hj=CEIL(k / q);

[0055] Where n_hj is the number of trusses;

[0056] q is the maximum spacing allowed between trusses.

[0057] In the prior art, it is usually required that the distance between the truss and the plate edge is not greater than 300mm, and the spacing is not greater than 600mm. Therefore, n_hj=CEIL(k / 600)

[0058] In this step, the CEIL function is used to obtain the calculation. The function of the CEIL function is to return the smallest integer greater than or equal to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com