Connecting assembly of assembly type component

A connecting component and prefabricated technology, applied in the direction of connecting components, building components, thin plate connections, etc., can solve the problems that the bolts cannot meet the high-strength connection requirements, the construction efficiency is low, and the operation of screwing the bolts is cumbersome.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments. The following examples are intended to illustrate the present invention, but not to limit the scope of the present invention.

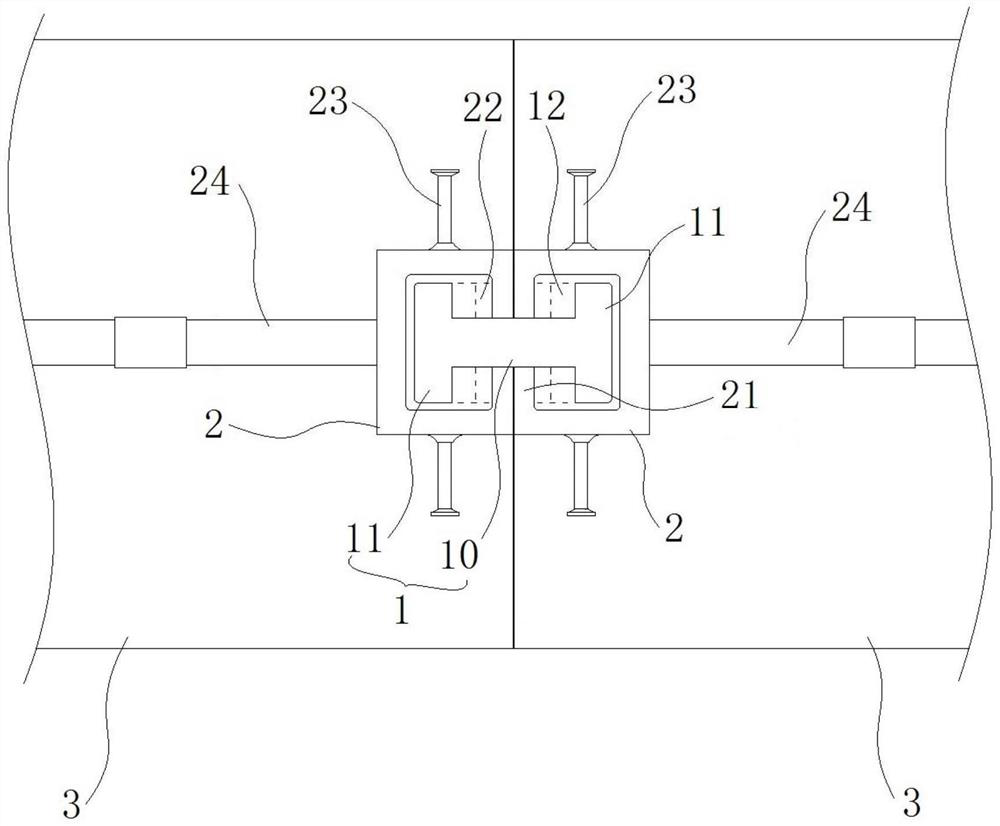

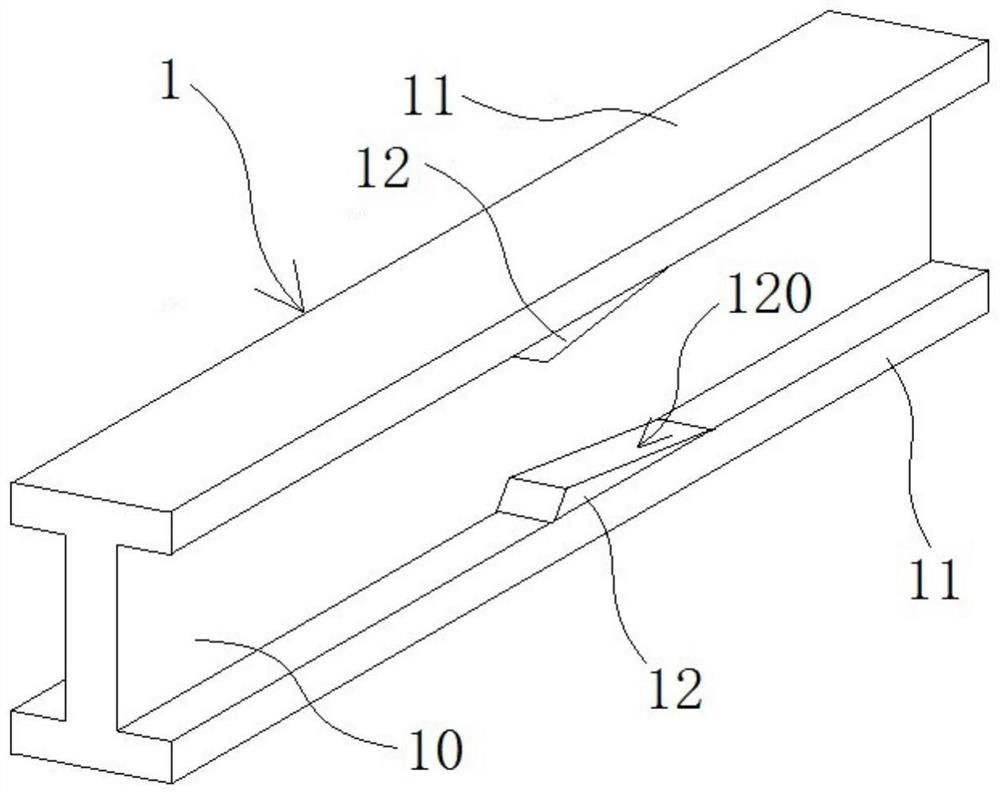

[0028] Specific embodiment 1 of the connection assembly of the assembled component of the present invention, such as Figure 1 to Figure 3 As shown, the connection assembly of the prefabricated component includes two C-shaped slots 2 and an I-shaped connector 1, the C-shaped slot 2 is provided with a component connection part for fixed connection with the component 3, and the I-shaped connector 1 includes The web 10 in the middle and the two side flanges 11, the notch of the C-shaped groove part 2 fits with the clearance of the web 10, and the side flanges 11 are used when the I-shaped connector 1 is inserted into the C-shaped groove part 2 It cooperates with the inversion edge 21 of the C-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com