High-pier hydraulic jacking integral type steel frame platform rollover construction system and construction method

An integral and lifting system technology, applied in the direction of erecting/assembling bridges, bridge parts, bridges, etc., can solve the problems of low construction progress and high process precision requirements, so as to improve work efficiency and construction quality, fast construction progress, eliminate The effect of fear of working at heights

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

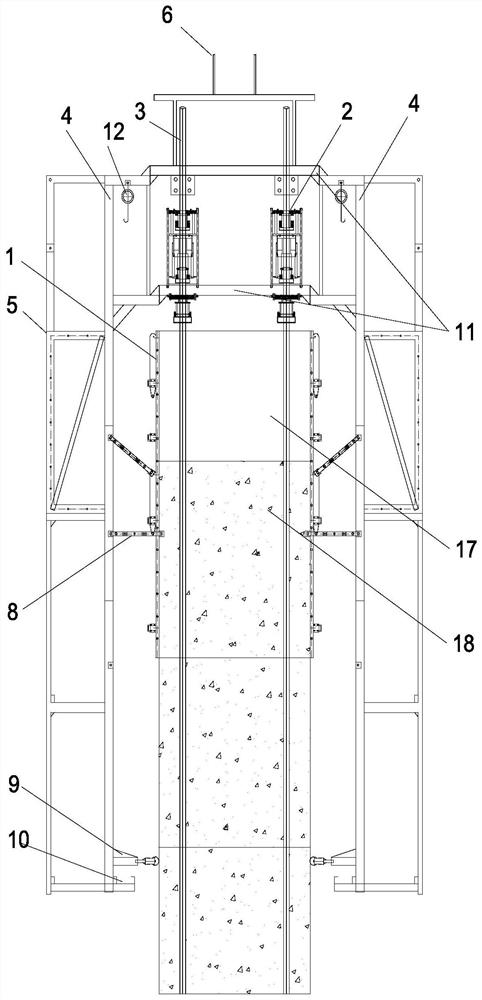

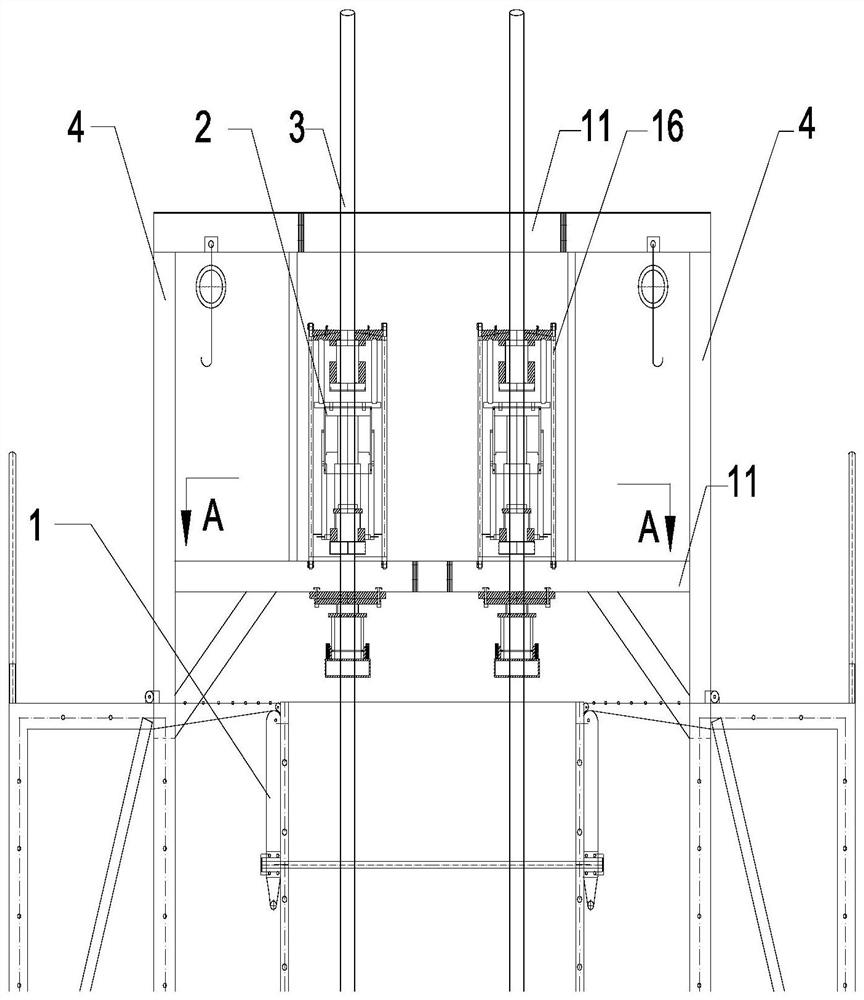

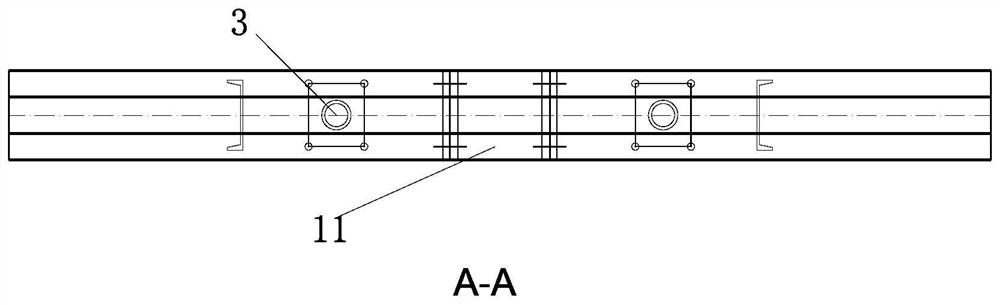

[0033] Such as Figure 1 to Figure 7 Shown is the high pier hydraulic jacking integrated steel frame platform turning form construction system of the present invention, which includes: hydraulic jacking system, steel frame platform system, formwork and formwork lifting system.

[0034] The hydraulic jacking system includes a support rod 3, a lifting frame 4, a hydraulic jack 2, a hydraulic solenoid valve, a hydraulic pump, and a hydraulic console. The support rod 3 is fixed on the ground foundation, and the hydraulic through-hole jack 2 is clamped on the support rod and climbs along the support rod. The hydraulic through-hole jack, the hydraulic solenoid valve and the hydraulic pump are connected to form a hydraulic working circuit through the hydraulic oil pipe, and the climbing height of the hydraulic through-hole jack is controlled by the hydraulic console. The lifting frame includes a plurality of outer vertical rods and a plurality of lifting frame beams passing through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com