Automatic glass bead repairing equipment and building construction vehicle

A technology of glass microbeads and microbeads, which is applied in construction, road repair, roads, etc. It can solve the problems that there is no way to repair, and it is difficult for the glass beads to be in a suitable inlay position, so as to achieve the adjustment of the center of gravity and balance adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

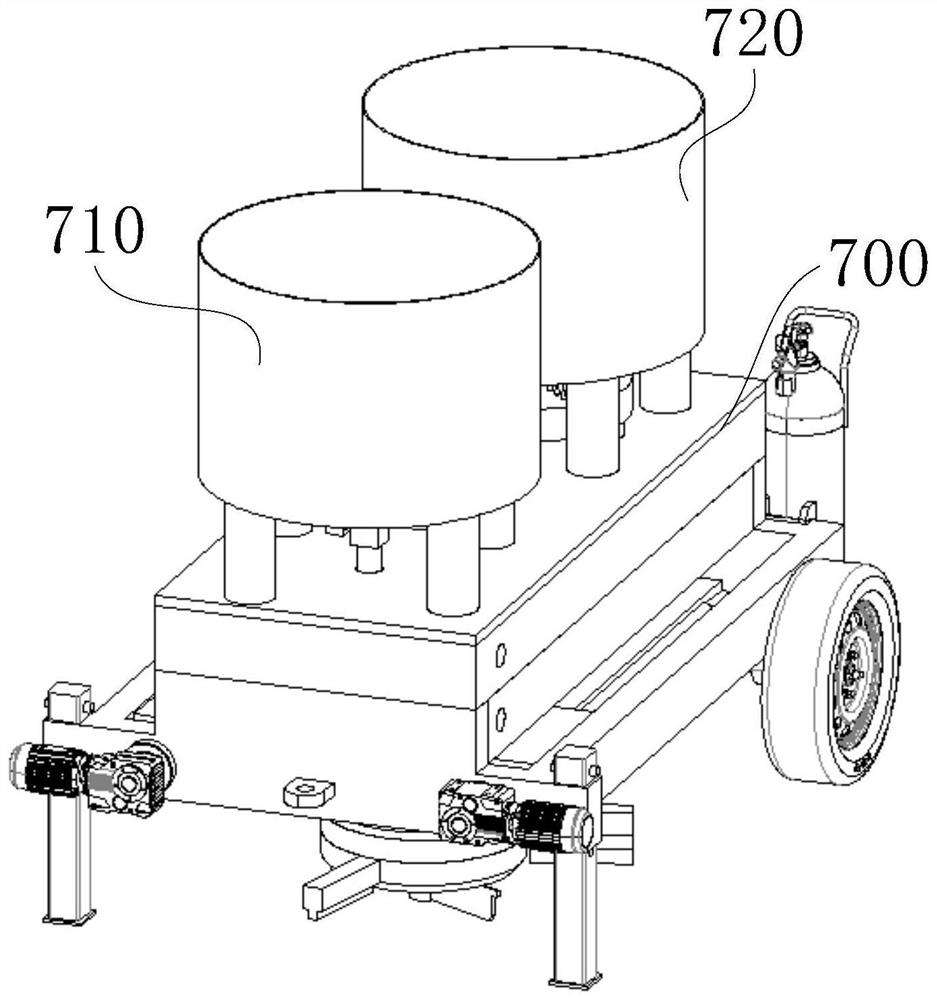

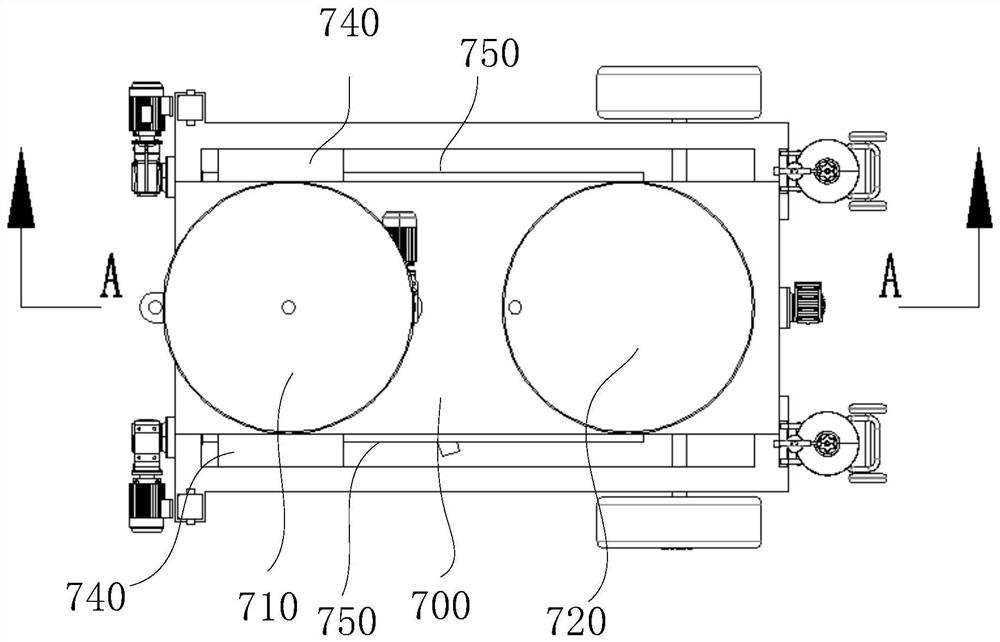

[0074] This embodiment provides a glass bead laying equipment, please refer to Figure 1 to Figure 8 ;include:

[0075] Microbead laying module 100, adhesive layer laying module 200 and rotating main body 300;

[0076] The bottom surface of the rotating main body 300 is set to be circular, and the bottom surface of the rotating main body 300 is configured as a manhole cover capable of covering the road surface;

[0077] The bead laying module 100 and the adhesive layer laying module 200 are connected to the rotating body 300 and can rotate around the axis of the rotating body 300;

[0078] The micro-bead laying module 100 is provided with a micro-bead discharge head 110, and the lower part of the micro-bead discharge head 110 is provided with a micro-bead discharge port, and the opening of the micro-bead discharge port is opened along the radial direction of the rotating main body 300;

[0079] The adhesive layer laying module 200 is provided with an adhesive layer discharge...

Embodiment 2

[0102] This embodiment provides a glass microbead repair device, please refer to Figure 1 to Figure 8 ,in particular:

[0103] Automated glass bead repair equipment, including:

[0104] Rotating main body 300, bead laying module 100, adhesive layer laying module 200, rotating scraper 500 and melting module 600;

[0105] The bottom surface of the rotating main body 300 is set to be circular and configured as a manhole cover capable of covering the road surface;

[0106] The microbead laying module 100, the adhesive layer laying module 200, the rotating scraper 500 and the melting module 600 are all connected to the rotating body 300 and can rotate around the central axis of the rotating body 300;

[0107] The micro-bead laying module 100 is provided with a micro-bead discharge head 110, and the lower part of the micro-bead discharge head 110 is provided with a micro-bead discharge port, and the opening of the micro-bead discharge port is opened along the radial direction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com