Efficient and accurate phosphorus removal system for slowing down membrane blockage and phase membrane corrosion

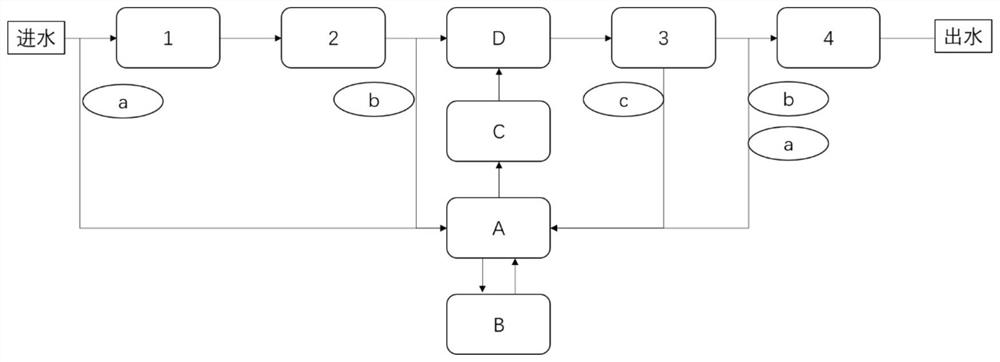

A membrane clogging and high-efficiency technology, used in water treatment parameter control, special treatment targets, water/sludge/sewage treatment, etc., can solve the problem of inability to adjust the dosage in real time, increase in the concentration of extracellular polymers, and increase the operation of sewage plants. cost and other issues, to achieve the effect of reducing the dosage of chemicals, refining operation management, and ensuring the quality of effluent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

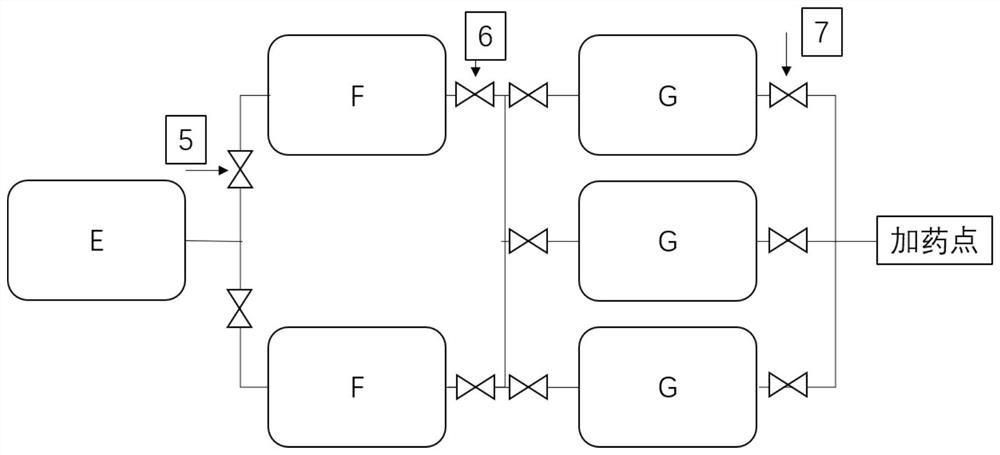

Method used

Image

Examples

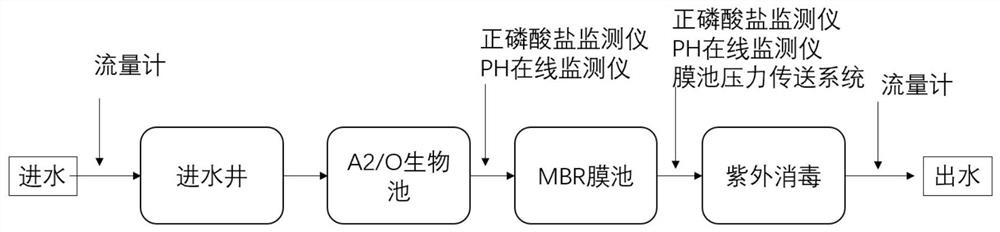

Embodiment 1

[0070] Sewage plant A 2 The TP concentration monitored at the outlet of the O biochemical tank aeration tank is 1.5mg / l, and the flow rate is 2080.6m 3 / h, the calculated theoretical phosphorus removal agent dosage is 3.07mg / L (calculated as iron).

[0071] The actual chemical dosage coefficient β used is 1.5, the actual dosage of phosphorus removal agent is 37.67mg / L, and the actual dosage of iron element is 0.6mg / L; the value of effluent safety factor is 1.1, of which chemical phosphorus removal The agent is polyaluminum ferric chloride, the effective content η of phosphorus removal agent is 10%, and the iron content is 1.6% (mass fraction).

[0072] Through real-time monitoring of the phosphate concentration at the outlet of the MBR membrane pool, the phosphate concentration at the outlet is 0.1mg / L. After the system simulation calculation, the value of β is adjusted to 1.35, and the dosage of phosphorus removal agent is 33.9mg / L. Finally, the effluent TP is realized. Con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com