Device and method for achieving adjustment of stress or position between two parts through inclined wedges

A technology of oblique wedges and parts, applied in the direction of lifting devices, fixing devices, hoisting devices, etc., can solve the problems of high cost, troublesome disassembly, and complexity, and achieve the effect of simple structure, low cost, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

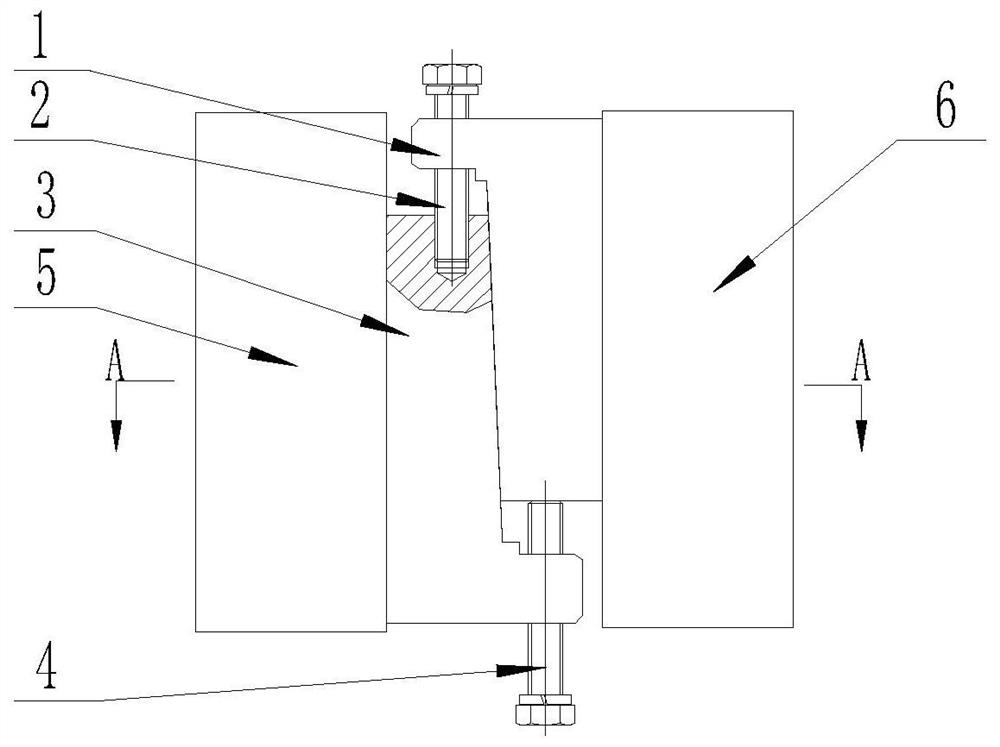

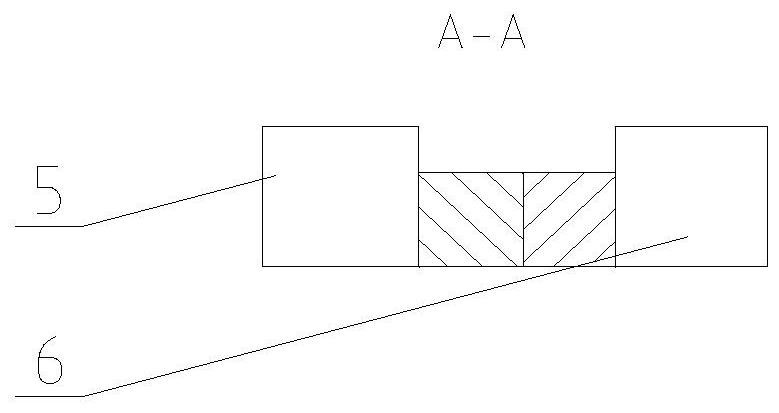

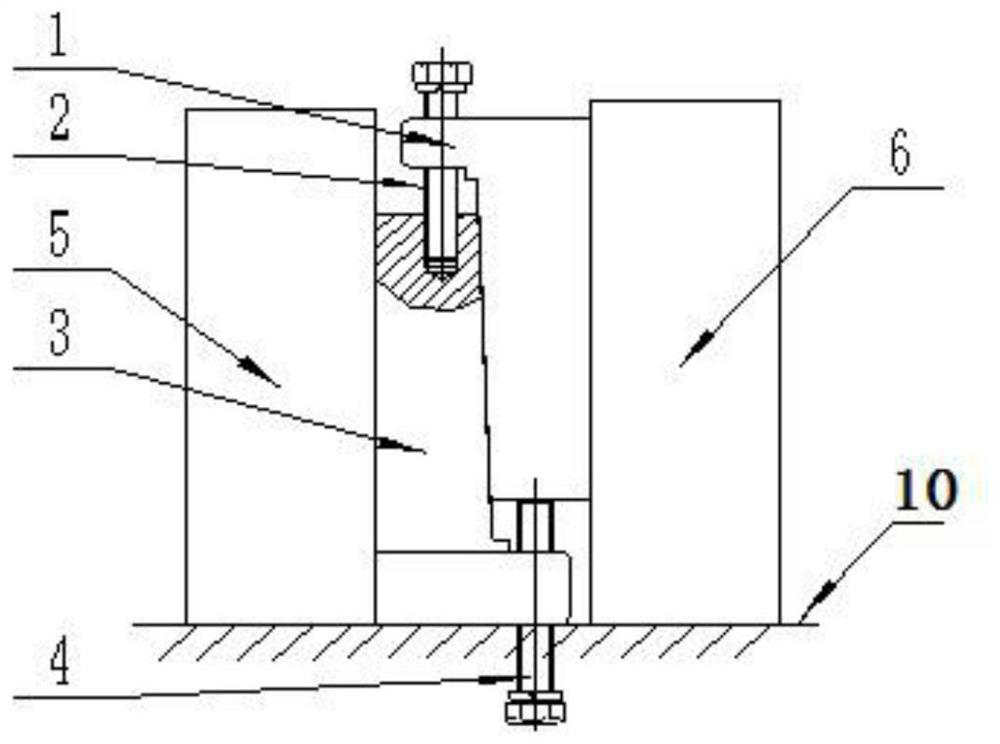

[0035] refer to Figure 1 to Figure 7 The shown device that utilizes a wedge to realize force or position adjustment between two components includes a first wedge 1, a second wedge 3, a first component 5, a second component 6, a fixing member, an adjusting member and a fixing seat 10 The first part 5 and the second part 6 are placed on the fixed seat 10; the first wedge 1 and the second wedge 3 are oppositely arranged between the first part 5 and the second part 6, And the first wedge 1 and the second wedge 3 are in contact with the first component 5 and the second component 6 or the second wedge 3 is fixedly connected with the first component 5, and the first wedge 1 is in contact with the second component 6; The fixing piece passes through one end of the first wedge 1 and is detachably fixed to one end of the second wedge 3 , and the adjusting piece passes through the other end of the second wedge 3 and abuts against the end of the first wedge 1 another side.

[0036] In a...

Embodiment 2

[0041] refer to figure 1 and image 3 The shown device using a wedge to realize force or position adjustment between two components differs from Embodiment 1 in that the first bolt 2 is used as the fixing member.

[0042] Preferably, the second bolt 4 is used for the adjustment member.

[0043] In actual use, the fixing part and the adjusting part adopt this technical solution, and only need to screw the first bolt 2 and the second bolt 4 to achieve the purpose of adjustment or locking, which is not only simple and convenient to operate, but also low in cost.

Embodiment 3

[0045] refer to figure 1 , image 3 , Figure 4 and Figure 5 The shown device using a wedge to realize force or position adjustment between two parts is based on Embodiment 1 or Embodiment 3: the first wedge 1 is an integrated structure composed of upper and lower parts; the first The upper part of the wedge 1 is a rectangular plate-like structure and one end is opened with a first through hole 8 for connecting the fixing member through the plate surface; the lower part of the first wedge 1 is a columnar body and one of the surfaces is a slope, and the other surfaces It is a plane; the contact side of the plate-shaped structure with the second component 6 is flush with the opposite side of the inclined surface on the columnar body.

[0046] Further, the width of the connecting end of the columnar body and the rectangular plate-like structure is greater than the width of the other end and smaller than the width of the rectangular plate-like structure.

[0047] In actual us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com