Production equipment and method for a puncture needle ultrasound region

A technology for production equipment and puncture needles, which is applied in the production equipment and manufacturing fields of the ultrasound area of puncture needles, and can solve problems such as inability to ensure operators, injuries, and patient injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

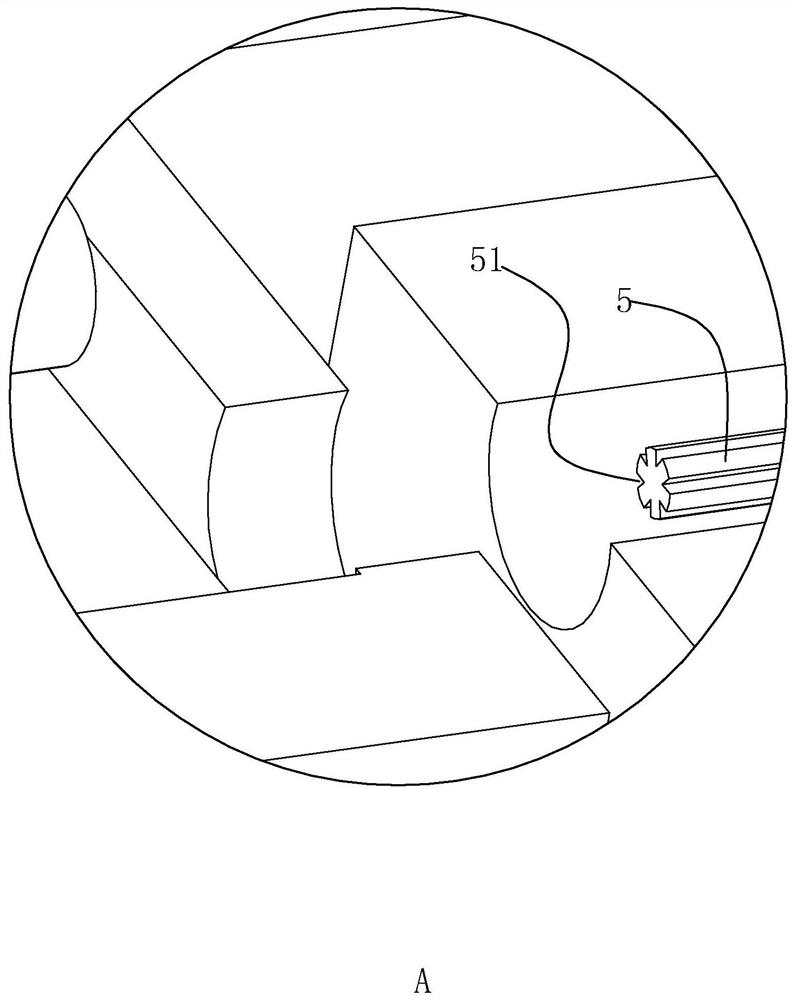

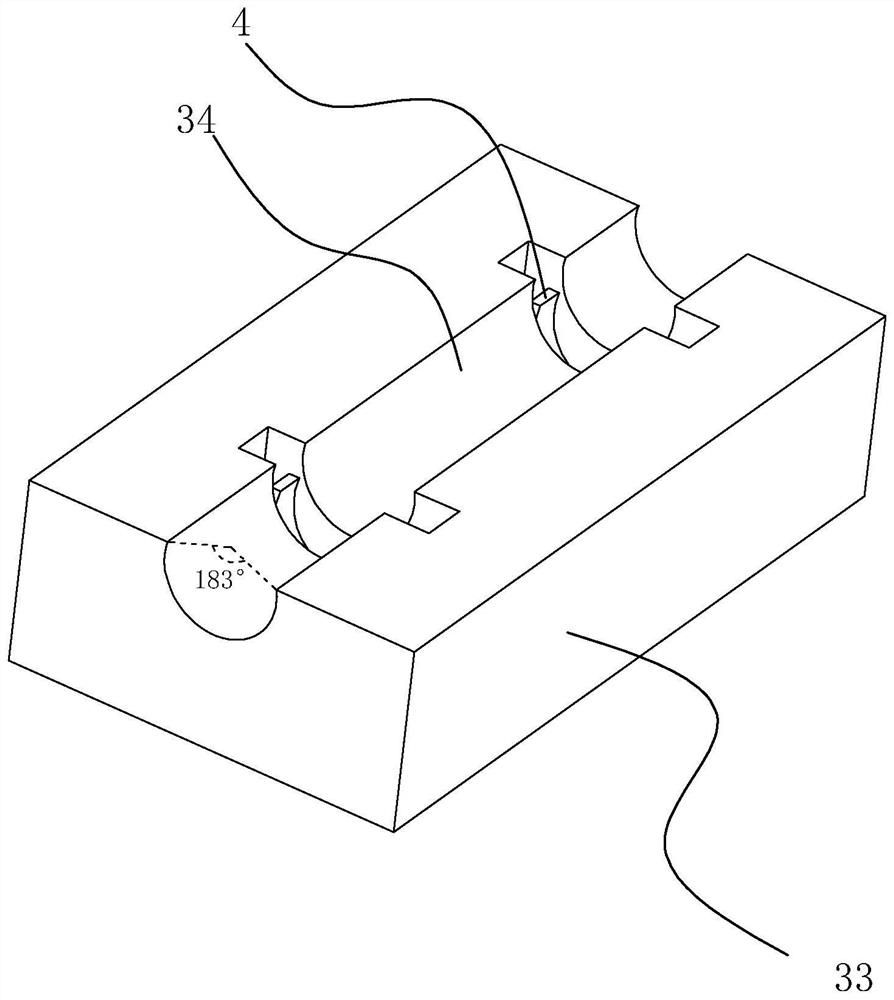

[0060] Example 1, such as Figure 1-Figure 4 As shown, a production equipment for a puncture needle ultrasound area includes a base 1, the base 1 is provided with two slide rails, the slide table 21 slides back and forth along the slide rails, and a screw assembly, and the screw assembly is driven by a servo motor, so the distance and frequency of sliding back and forth of the slide table 21 can be controlled by controlling the servo motor.

[0061] One side of the slide table 21 is provided with a jaw 22, which is a chuck; the jaw 22 can be automatically opened and closed by PLC control; the jaw 22 is connected to the motor shaft of the first motor 23, and the first motor 23 is a servo motor. The forward and reverse rotation of the clamp mouth 22 can be controlled by controlling the forward and reverse rotation of the first motor 23 .

[0062] Therefore, through the cooperation of the slide table 21 and the first motor 23, the forward and reverse rotation and the back and fo...

Embodiment 2

[0075] Embodiment 2, a manufacturing method of a puncture needle.

[0076] (1) Prepare the needle core of the puncture needle:

[0077] Take the stainless steel billet, cut it into a rod, then heat the rod, stretch it step by step through the drawing die, cool it, and then cut it to form a needle core column of the required length and diameter;

[0078] Using a cutting grinder to cut the head of the needle core column to form a needle point with a piercing edge surface, and then obtain a rough needle core product with a needle point;

[0079] placing the obtained needle core crude product in an abrasive suspension, and using ultrasonic waves to vibrate the abrasive suspension to polish the needle core to obtain a polished needle core;

[0080] (2) Prepare the needle tube of the puncture needle:

[0081] Take a stainless steel billet, subject it to hot extrusion treatment at a temperature of 260°C to form a stainless steel thick plate, and then water quench the stainless stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com