Laser lettering device for chess manufacturing

A technology of laser engraving and chess, which is applied in the direction of manufacturing tools, laser welding equipment, and devices for coating liquid on the surface, etc., can solve the problems of low safety and low work efficiency, and achieve increased safety, improved work efficiency, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

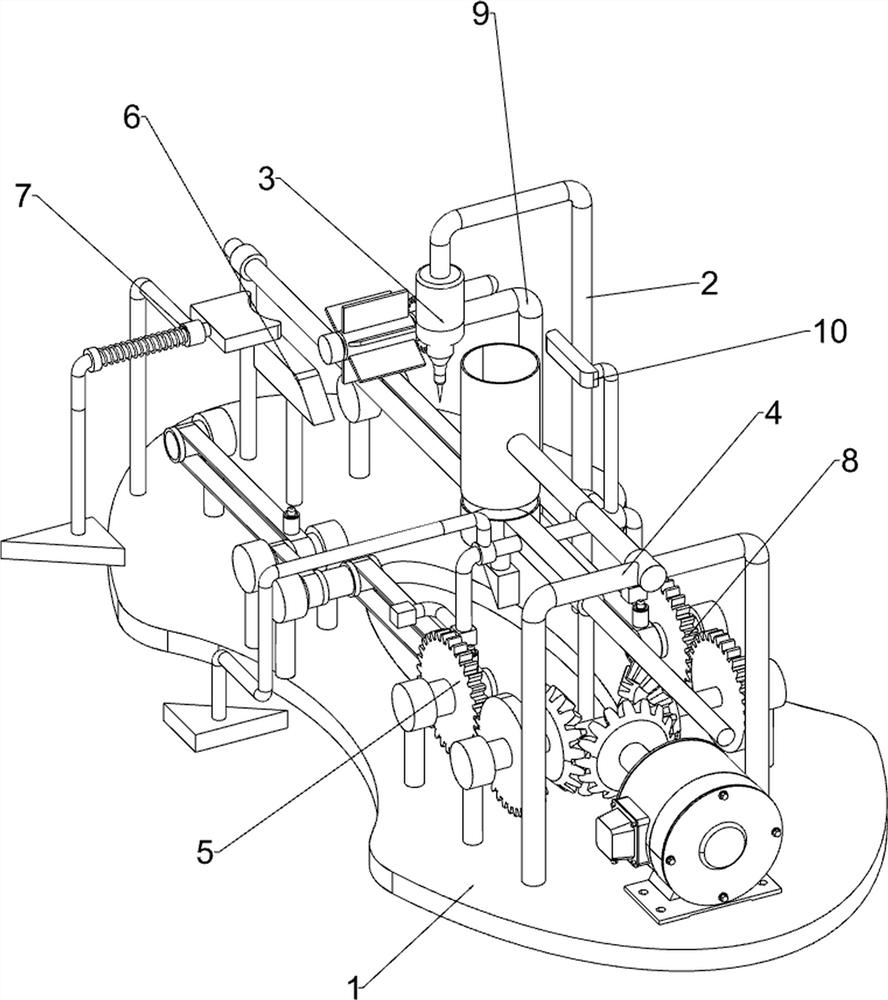

[0074] A kind of laser engraving device for making chess, such as figure 1 As shown, it includes a bottom plate 1, a support column 2, a laser knife 3 and a feeding and engraving mechanism 4. A support column 2 is provided in the middle of the top rear side of the bottom plate 1, a laser knife 3 is provided on the upper side of the front of the support column 2, and a laser knife 3 is provided in the middle of the bottom plate 1. There is a feeding and engraving mechanism 4.

[0075] When people need to engrave letters to the round wood block, the round wood block is all put into a certain part of the fetching and engraving mechanism 4 earlier, and the fetching pushes the engraving mechanism 4 to transmit the round block to the left to the front of the laser knife 3. Below, turn on the laser knife 3, and the laser knife 3 engraves characters on the circular wooden block. After the word is engraved, turn off the laser knife 3, and then remove the engraved circular wooden block....

Embodiment 2

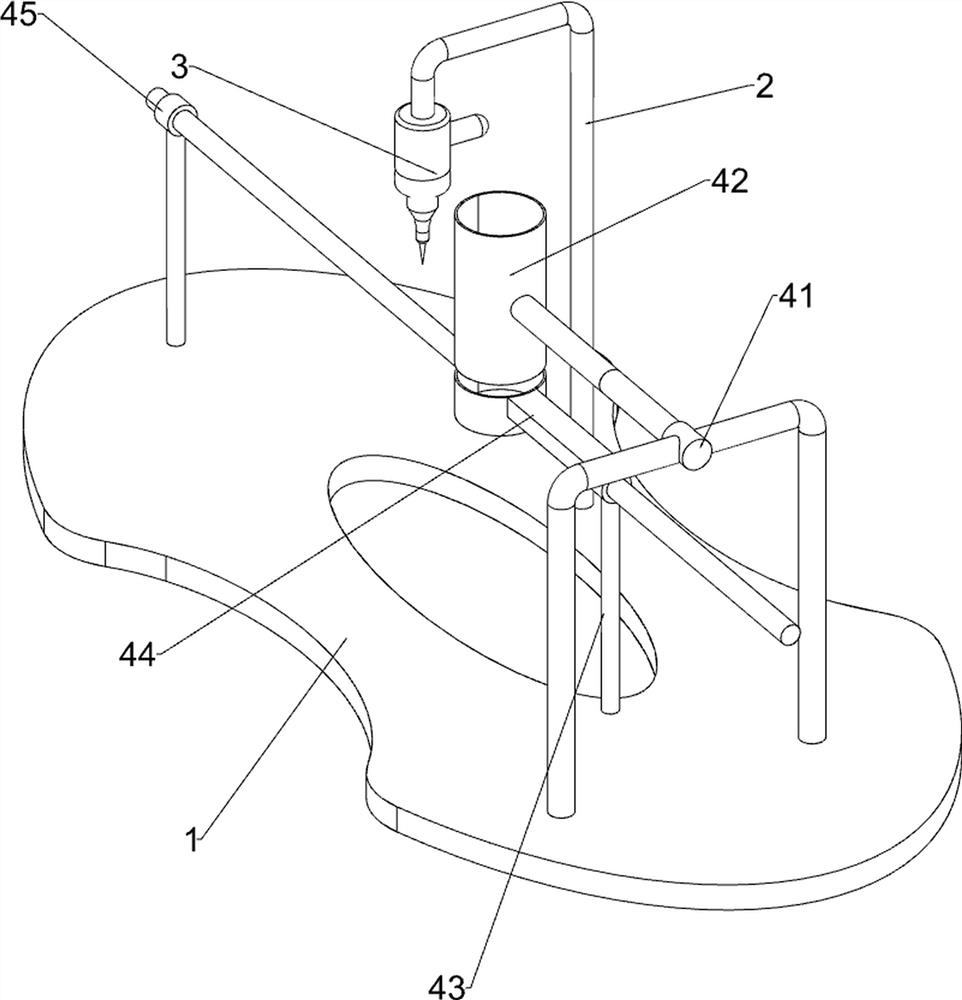

[0077] On the basis of Example 1, such as figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the material fetching and pushing engraving mechanism 4 includes a first fixed frame 41, a material storage frame 42, a first sliding sleeve 43, a discharging sliding plate 44 and a second sliding sleeve 45, and the right side of the bottom plate 1 top is provided with a first fixing bracket. frame 41, the left side of the first fixed frame 41 top is provided with material storage frame 42, the middle of bottom plate 1 top right side is provided with first sliding sleeve 43, the middle of bottom plate 1 top left side is provided with second sliding sleeve 45, the first sliding sleeve 43 tops and the second sliding sleeve 45 tops are slidably provided with discharging sliding plate 44 .

[0078] When people need to engrave letters on the round wooden blocks, the round wooden blocks are all put into the material storage frame 42 earlier, and the circular wooden bloc...

Embodiment 3

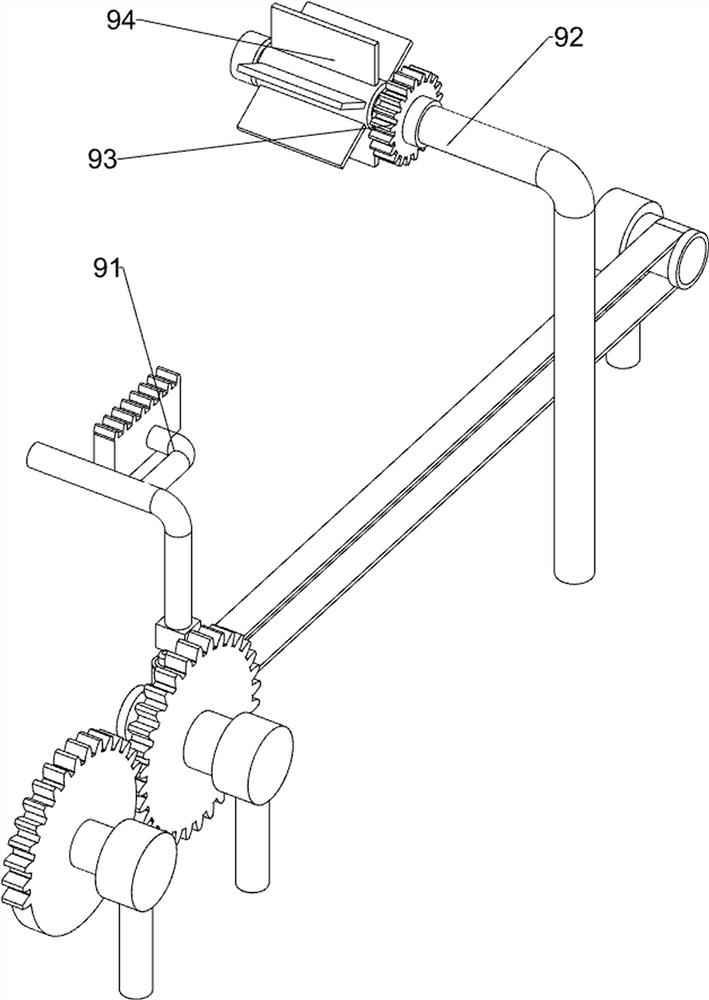

[0084] On the basis of Example 2, such as Figure 7 , Figure 8 and Figure 9 As shown, it also includes a push-out blanking mechanism 7, and the push-out blanking mechanism 7 includes a first connecting rod 71, a fixed sliding sleeve 72, a wedge 73, a drive wedge 74 and a first spring 75, and the first drive block 511 top The front side is provided with the first connecting rod 71, the left front part of the bottom plate 1 top is provided with a fixed sliding sleeve 72, and the sliding type on the right side of the fixed sliding sleeve 72 is provided with a driving wedge 74, and the front side of the first connecting rod 71 bottom and the driving wedge are arranged. The front side of the bottom of the wedge 74 is provided with a wedge 73, and the wedge 73 cooperates to drive the first spring 75 between the front of the top of the wedge 74 and the upper right side of the front of the fixed sliding sleeve 72. The first spring 75 covers Drive wedge 74 outsides.

[0085] When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com