Pinhole structure for mems probe laser etching device

A laser etching and pinhole technology, which is used in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of complex probe structure, irregular laser ablation pattern, and no discovery, and achieves wide applicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0133] The following is the specific implementation of the MEMS probe laser etching device of the present invention.

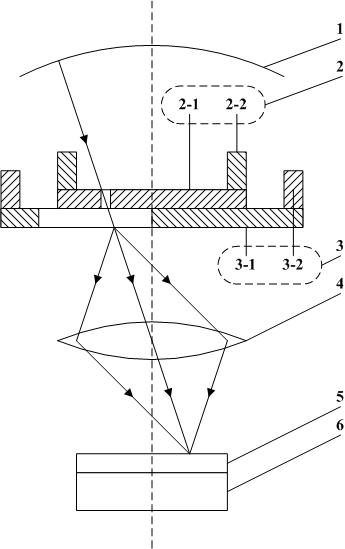

[0134] The structure schematic diagram of MEMS probe laser etching device under this embodiment is as follows figure 1 As shown, in the MEMS probe laser etching device, according to the light propagation direction, an arc light source 1, a spiral channel plate 2, a straight channel plate 3, an objective lens 4, a single crystal silicon wafer 5 and a four-dimensional station 6;

[0135] Each point of said arc light source 1 is identical to object lens 4 center distances, and promptly the shape of arc light source 1 is the circular arc shape taking object lens 4 center as the center; The line connecting the center is vertical;

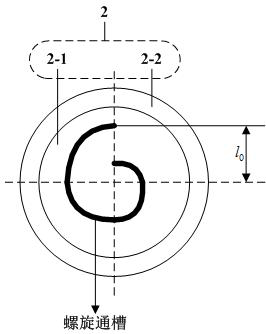

[0136] The structural representation of the spiral channel plate 2 is as follows: figure 2 As shown, it includes a first bottom plate 2-1 with a spiral groove and a first side 2-2 with a circular cross-section. The outer surface of t...

specific Embodiment approach 2

[0143] The following is the specific implementation of the MEMS probe laser etching device of the present invention.

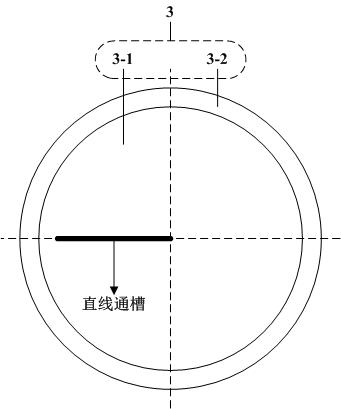

[0144] The MEMS probe laser etching device under this embodiment is further defined on the basis of Embodiment 1: a scraper is arranged around the linear through groove of the second bottom plate 3-1, and a scraper is arranged on the upper surface of the second bottom plate 3-1. There are a plurality of annular grooves concentric with the second bottom plate 3-1, and the annular grooves start and stop at the scrapers around the straight through groove; the upper surface of the second bottom plate 3-1 is also provided with linear grooves in the radial direction, and the annular grooves It communicates with the linear groove crosswise, and the annular groove and the linear groove are filled with lubricating oil, such as Figure 5 As shown, the lubricating oil drips from between the first side 2-2 and the second side 3-2.

specific Embodiment approach 3

[0145] The following is the specific implementation of the MEMS probe laser etching device of the present invention.

[0146] The MEMS probe laser etching device under the present embodiment is further limited on the basis of the specific embodiment one or the specific embodiment two: the structure of the MEMS probe laser etching device, such as Figure 6 As shown, the first side 2 - 2 is externally meshed with a gear 7 , and the rotation of the gear is controlled by a motor 8 , the motor 8 is connected to a controller 9 , and the controller 9 is connected to the four-dimensional table 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com