Spraying device for producing and processing fan blades

A technology of spraying device and fan blade, which is applied to spraying device, cleaning method using tools, device for coating liquid on the surface, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A spraying device for the production and processing of fan blades, including a box body 1, a first cavity 2 and a second cavity 3 are arranged inside the box body 1, and a feed plate 21 is fixedly installed in the middle of the upper end of the box body 1 , the lower middle position of the feed plate 21 is provided with two rotating shafts 17 running through the front and rear ends of the box body 1, and the two rotating shafts 17 are located in the two rotating shafts 17 inside the first cavity 2, and the outer walls of the two rotating shafts 17 are uniform. Rollers 18 are fixedly installed, and the outer walls of the two rollers 18 are fixedly equipped with a plurality of bristles, and the outer walls of the two rotating shafts 17 are fixedly equipped with pulleys 20 near the front ends, and the two pulleys 20 are crossed. Belt, the front end of one of the two pulleys 20 is fixedly equipped with a second motor 19, and the second motor 19 is fixedly connected to the fr...

Embodiment 2

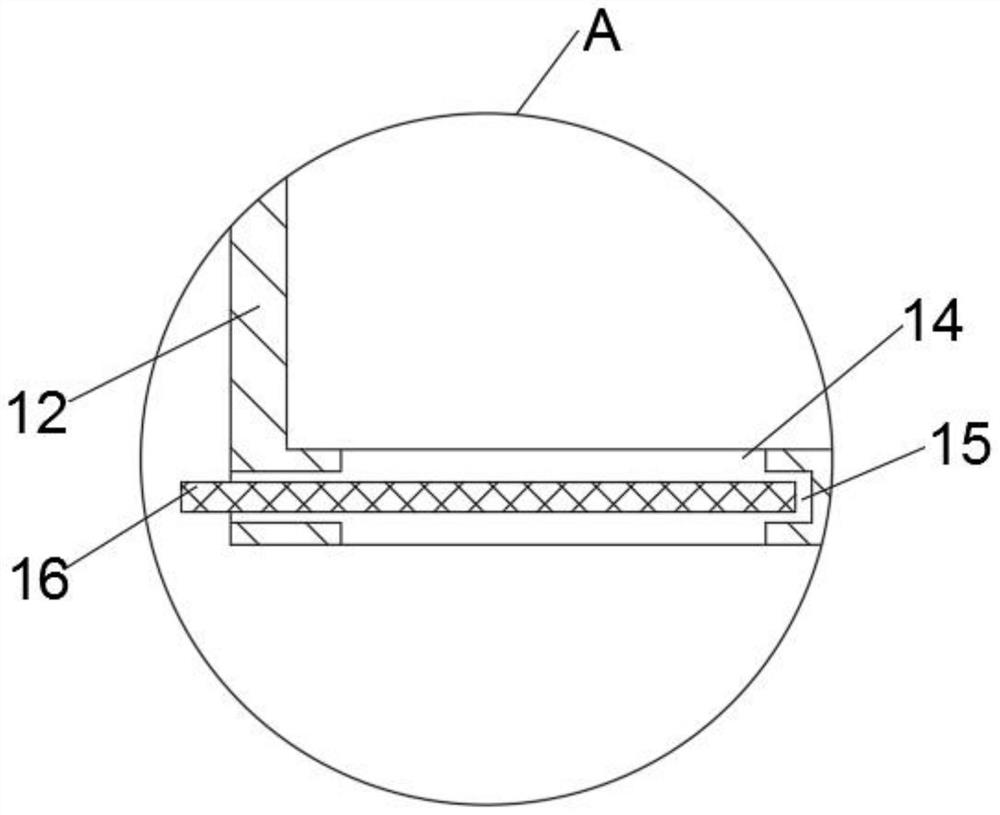

[0034] One side of the first cavity 2 is provided with a third opening opened on the side wall of the box body 1. The side of the third opening is provided with a mounting frame 12 fixedly connected to the side wall of the box body 1, and one side of the mounting frame 12 is fixedly installed. There is a first support plate, and the lower end of the first support plate is fixedly installed with a first motor 13, and one side of the first motor 13 is fixedly installed with a movable rod that runs through the installation frame 12, and the outer wall of the movable rod is fixedly installed with two fans. Leaves, the lower end inner wall of the installation frame 12 is provided with a through groove 14, and the lower end side wall of the installation frame 12 is provided with an installation groove 15, the installation groove 15 communicates with the through groove 14, and the inside of the installation groove 15 is equipped with a dust filter plate 16.

Embodiment 3

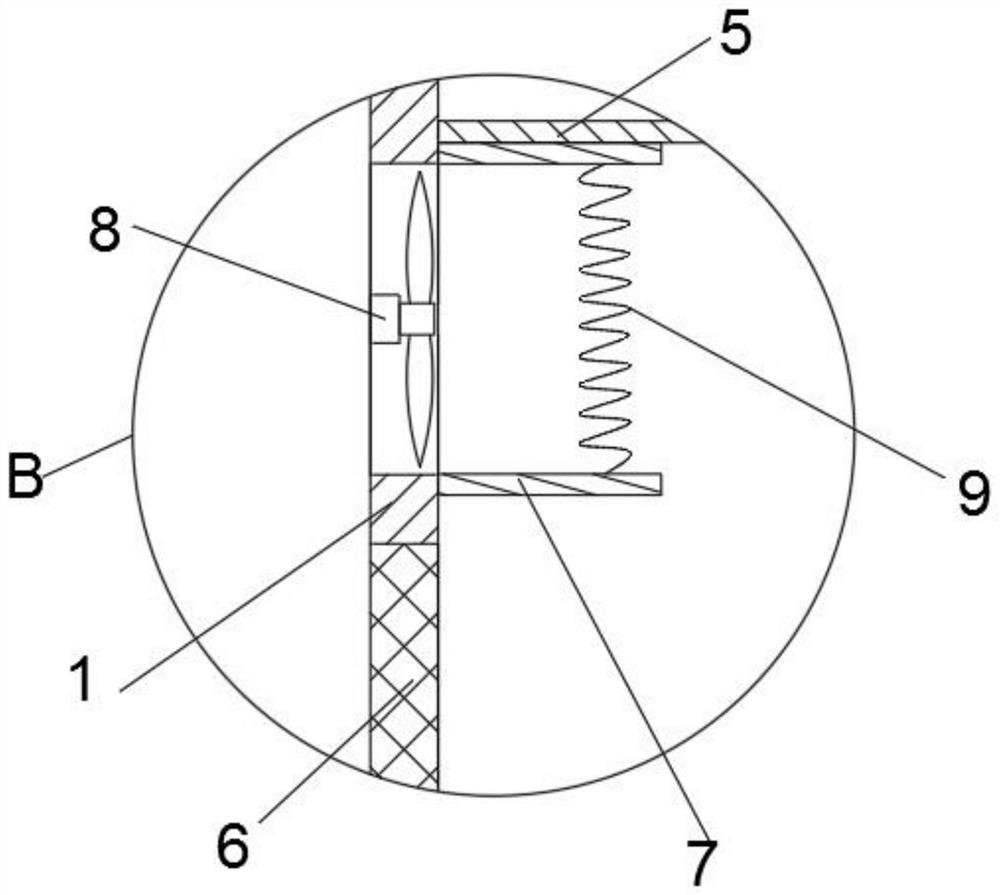

[0036] A first opening is provided between the first cavity 2 and the second cavity 3, and two spray guns 4 penetrating through the side walls of the box body 1 are provided below the first opening, and two spray guns 4 are provided below the two spray guns 4 with The baffles 5 fixedly connected to the side walls at the front and rear ends of the box body 1;

[0037] The bottom of the baffle plate 5 is provided with two drying assemblies, the drying assembly includes a fan body 8 fixedly installed on the side wall of the box body 1, and one side of the fan body 8 is provided with a heating wire 9, and the upper and lower ends of the heating wire 9 are fixed. A horizontal plate 7 is installed, and both horizontal plates 7 are fixedly connected with the side wall of the box body 1;

[0038] Two groups of drying components are arranged on both sides of the box body 1 respectively. The two groups of drying components are arranged in opposite directions. The two groups of drying co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com