A kind of screen printing fluorescent shoe upper and its preparation process

A preparation process and a technology for shoe uppers, which are applied in the directions of shoe uppers, footwear, and shoe-making machinery, etc., can solve the problems of not being able to provide lighting functions and having no luminous effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A silk screen fluorescent shoe upper, the fluorescent shoe upper is composed of a shoe upper and a fluorescent material, the material of the shoe upper is textile canvas and PU leather material, the main components of the fluorescent material are: vinyl resin and fluorescent powder, the characteristics of vinyl resin There are: yellow-brown viscous liquid, acid value 8-12MGKOH / G, viscosity 300-500MPAS / 25℃, gel time 6-22MIN / 25℃, thermal stability ≥ 24H / 80℃, heat distortion temperature 150-160 ℃, the phosphor adopts SRAI204:EU(2+).

[0035] Vinyl resin contains solid particles, the content of solid particles is 58-66%, the ratio of vinyl resin to phosphor is 1:1, solid particles are divided into small particles and medium particles, and the size of solid particles is 0.1-2mm .

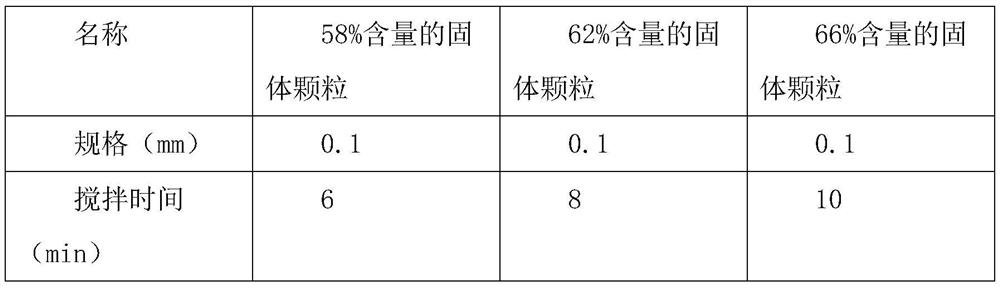

[0036] Table 1: Specifications and stirring time of solid particles with different contents in Example 1

[0037]

Embodiment 2

[0039] A silk screen fluorescent shoe upper, the fluorescent shoe upper is composed of a shoe upper and a fluorescent material, the material of the shoe upper is textile canvas and PU leather material, the main components of the fluorescent material are: vinyl resin and fluorescent powder, the characteristics of vinyl resin There are: yellow-brown viscous liquid, acid value 8-12MGKOH / G, viscosity 300-500MPAS / 25℃, gel time 6-22MIN / 25℃, thermal stability ≥24H / 80℃, heat distortion temperature 150-160 ℃, the phosphor adopts SRAI204:EU(2+).

[0040]Vinyl resin contains solid particles, the content of solid particles is 58-66%, the ratio of vinyl resin to phosphor is 1:1, solid particles are divided into small particles and medium particles, and the size of solid particles is 0.1-2mm .

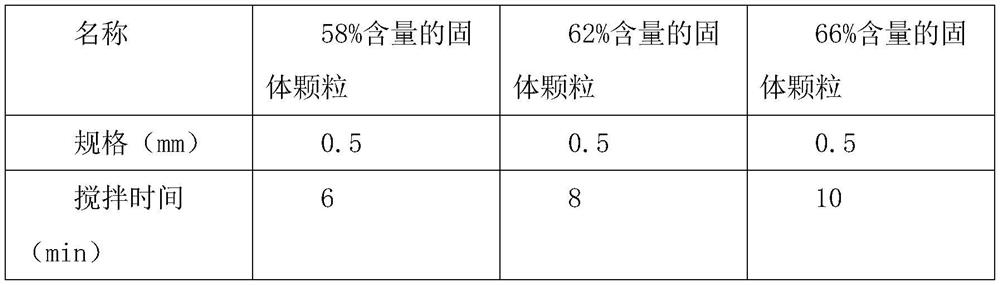

[0041] Table 2: Specifications and stirring time of solid particles with different contents in Example 2

[0042]

Embodiment 3

[0044] A silk screen fluorescent shoe upper, the fluorescent shoe upper is composed of a shoe upper and a fluorescent material, the material of the shoe upper is textile canvas and PU leather material, the main components of the fluorescent material are: vinyl resin and fluorescent powder, the characteristics of vinyl resin There are: yellow-brown viscous liquid, acid value 8-12MGKOH / G, viscosity 300-500MPAS / 25℃, gel time 6-22MIN / 25℃, thermal stability ≥ 24H / 80℃, heat distortion temperature 150-160 ℃, the phosphor adopts SRAI204:EU(2+).

[0045] Vinyl resin contains solid particles, the content of solid particles is 58-66%, the ratio of vinyl resin to phosphor is 1:1, solid particles are divided into small particles and medium particles, and the size of solid particles is 0.1-2mm .

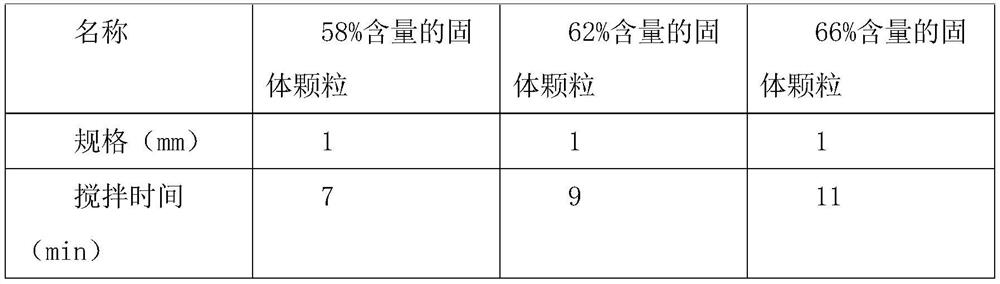

[0046] Table 3: Specifications and stirring time of solid particles with different contents in Example 3

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com