A temperature control method and device for an immersion photolithography machine

A temperature control method and temperature control technology, which are used in temperature control, photolithographic process exposure devices, optomechanical equipment, etc., can solve the problems of lack of secondary temperature control, high temperature control parameter measurement requirements, and lack of temperature control flexibility. , to overcome the influence and ensure the accuracy and stability of temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0094] In order to make the objects, technical solutions and advantages of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and examples. It is to be understood that the specific embodiments described herein are intended to explain the present invention and is not intended to limit the invention.

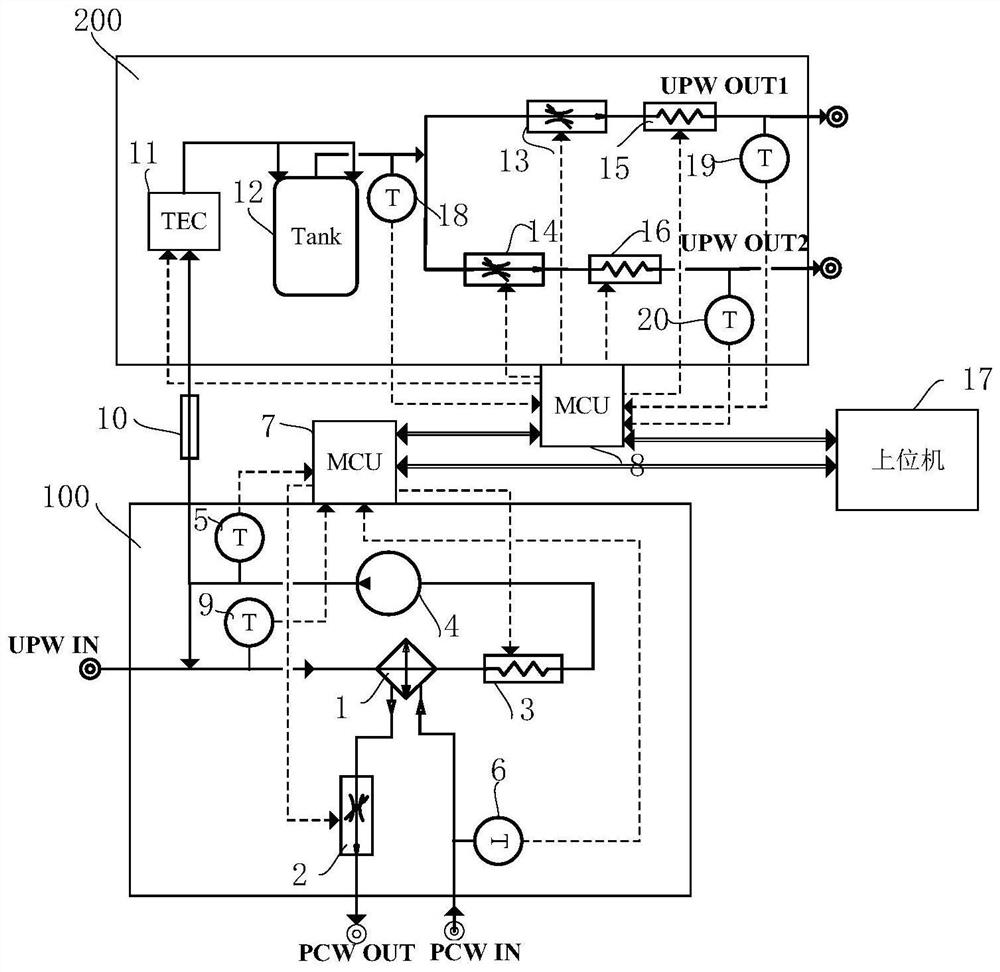

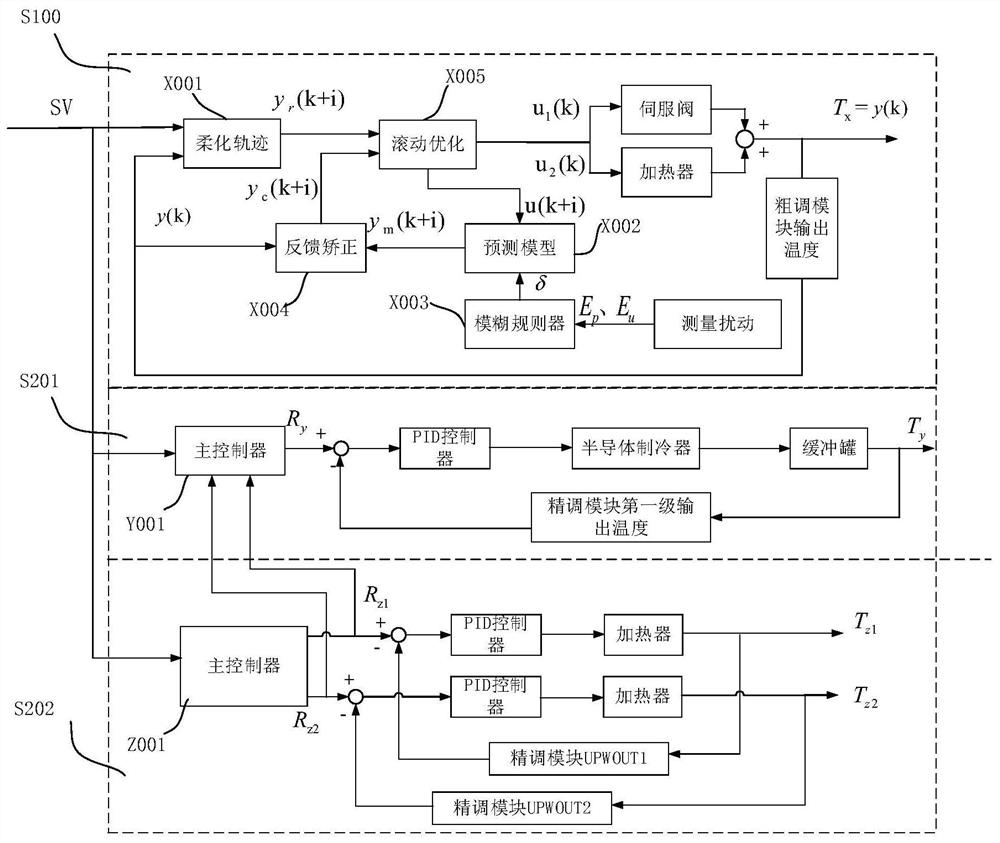

[0095] To this end, the present invention provides an effective method of controlling the temperature of the immersion, the use of multi-stage heat exchanger, and a plurality of servo flow control, to achieve steady-state accuracy of + / - 0.01 ℃.

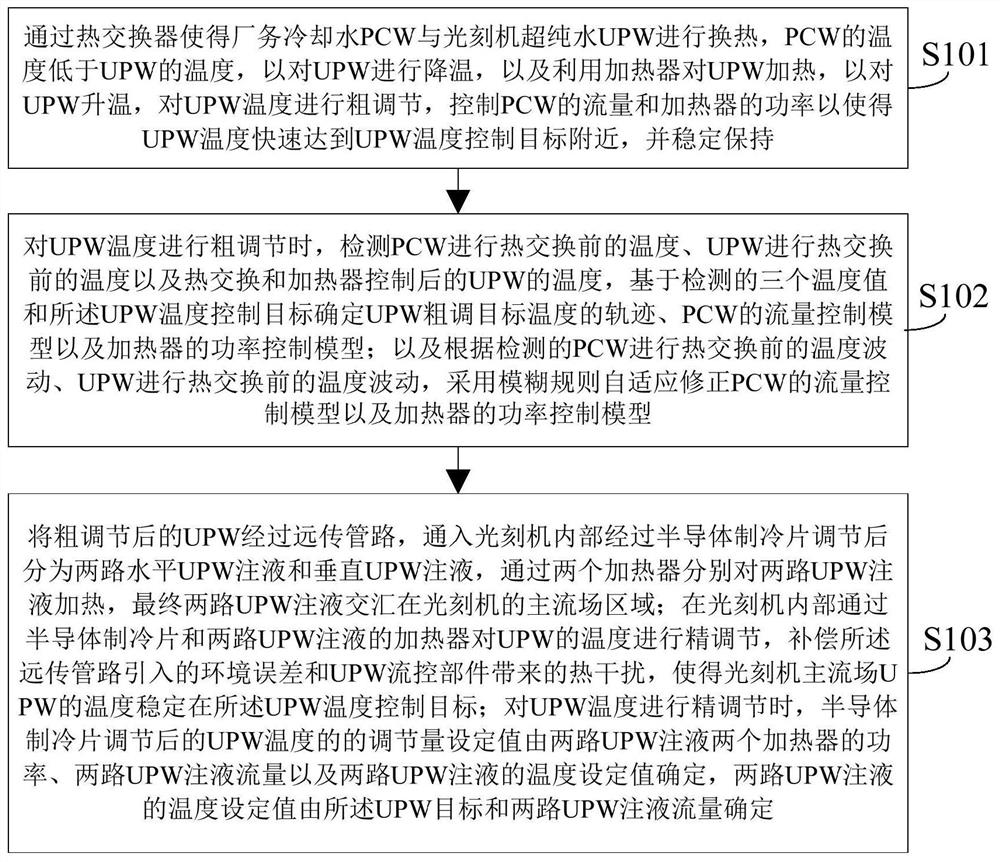

[0096] specifically, figure 1 The method of controlling the temperature of a flowchart of an immersion lithography machine according to an embodiment of the present invention; as figure 1 As shown, including the following steps:

[0097] S101, through the heat exchanger so that the cooling water PCW Facility with UPW for lithography ultrapure water heat exchanger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com