A furniture flatness detection device

A detection device and flatness technology, applied in the direction of mechanical roughness/irregularity measurement, etc., can solve the problems of small height and low drop, and achieve the effect of increasing reliability, avoiding deviation and good maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

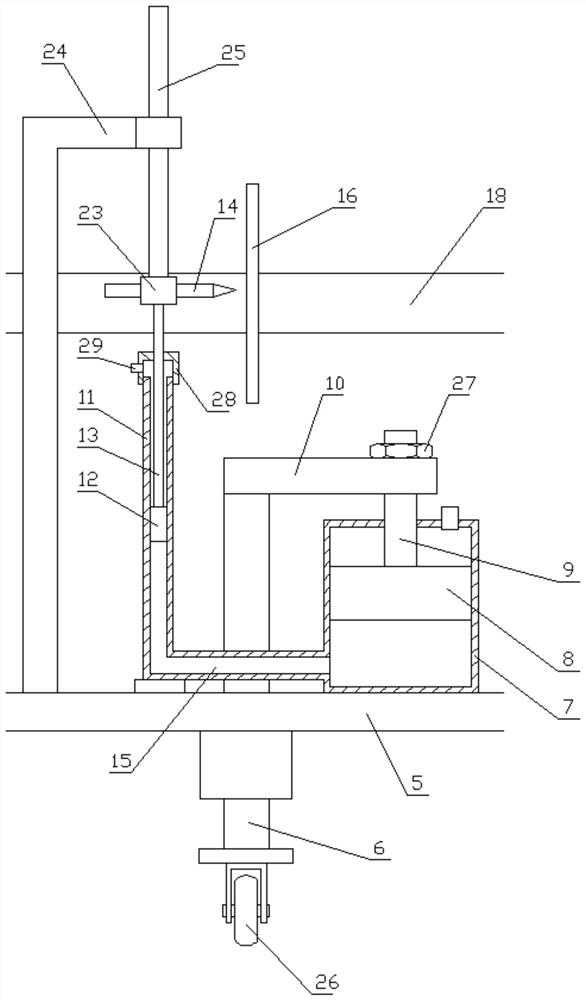

[0031] like figure 1 , 2 As shown, this embodiment is a furniture flatness detection device, which is characterized in that it includes a base 1, the base is provided with a detection structure 2, and a lifting structure 3 is provided below the detection structure 2;

[0032] The detection structure 2 includes two lead screw drive mechanisms 4 arranged in parallel, the lead screw drive mechanism 4 is movably connected to the same beam 5, and the beam 5 is movably provided with a probe rod 6 whose degree of freedom is up and down movement;

[0033] The beam 5 is provided with a first piston cylinder 7 close to the probe rod 6, the first piston cylinder 7 is provided with a first piston ring 8, the upper side of the first piston ring 8 is connected with a first piston rod 9, and the upper end of the first piston rod 9 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com