Optical fiber electric field sensor based on F-P interference principle and method thereof

An optical fiber sensor, optical fiber electric field technology, applied in electrostatic field measurement, instrument, measurement of electrical variables, etc., can solve the problems of large volume and complex optical path, and achieve the effect of small size, high sensitivity and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the drawings and embodiments.

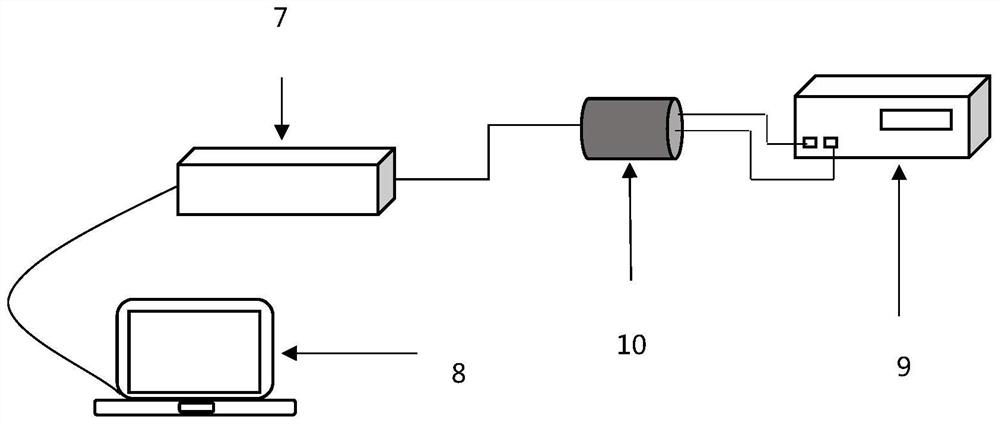

[0034] see figure 2 , a fiber optic electric field sensor based on the F-P interference principle, comprising a fiber optic electric field sensor 10, characterized in that two electrodes of the fiber optic electric field sensor 10 are connected to an adjustable DC voltage source 9, and the optical fiber is connected to the fiber optic sensor demodulator 7 The optical channel is connected; the communication interface end of the optical fiber sensor demodulator 7 is connected with the computer 8 .

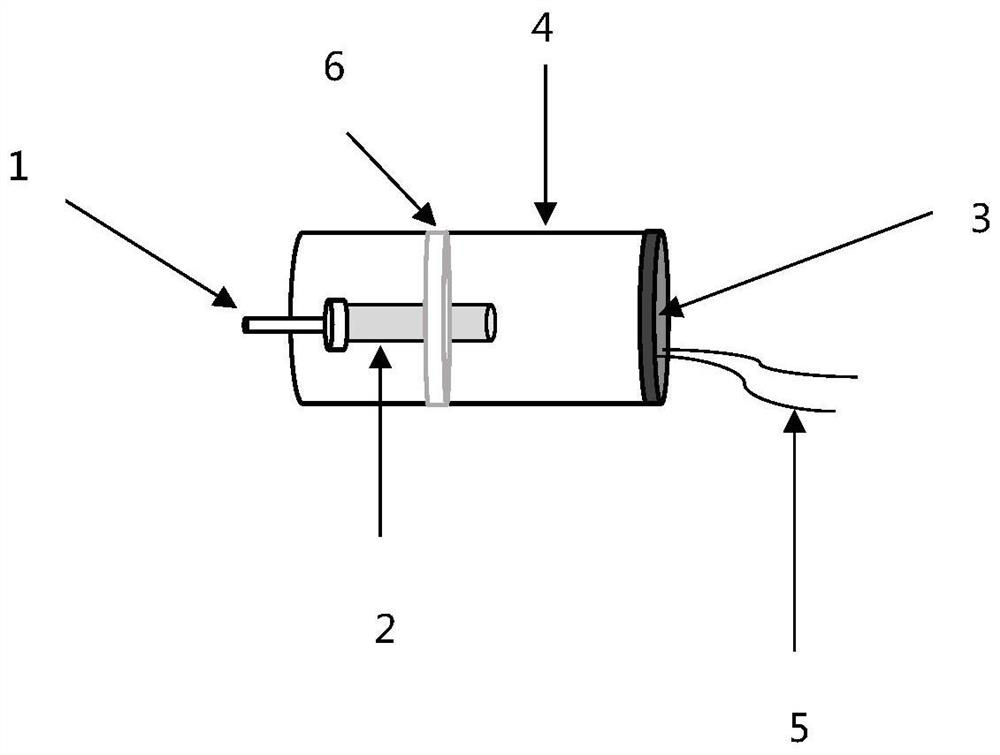

[0035] see figure 1 , the optical fiber electric field sensor 10 includes a stainless steel tube 4, the inner cavity of the stainless steel tube 4 is provided with a plastic plate 6; the plastic plate 6 is plugged with a ceramic pin 2, and the left end of the ceramic pin 2 is plugged with an optical fiber 1; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com