Electromechanical equipment failure troubleshooting device

A technology for troubleshooting, electromechanical equipment, applied in the direction of lifting device, measuring device, measuring device casing, etc., can solve the problems of inconvenient handling, large size, and inconvenient maintenance by staff, and achieve the effect of easy maintenance and improved portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

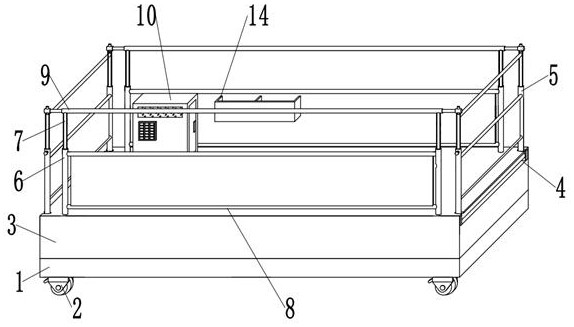

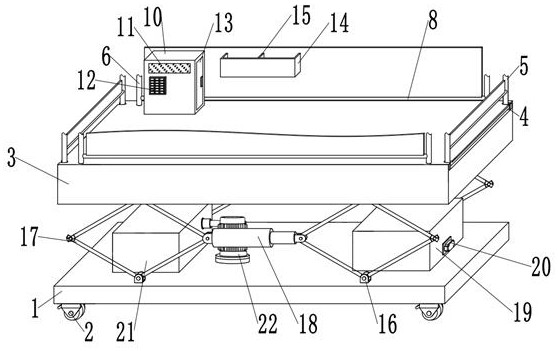

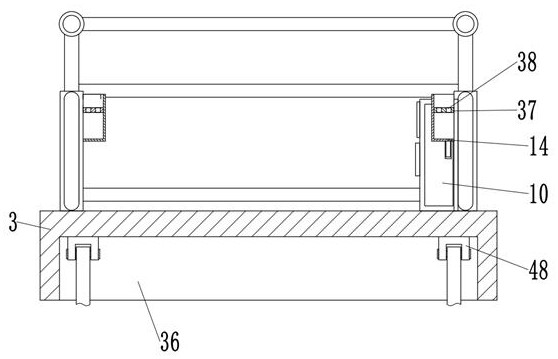

[0044] The present invention provides a fault maintenance device for electromechanical equipment, comprising a bottom plate 1 and a top plate 3. Universal wheels 2 are installed on the bottom outer wall of the bottom plate 1 near the four corners through bolts. The universal wheels 2 facilitate the movement of the maintenance equipment, and the bottom outer wall of the top plate 3 There are grooves 36 on the top, and two fixing seats 48 are installed on both sides of the inner wall of the top of the groove 36 by bolts, and two bases 16 are installed on both sides of the outer wall of the top of the bottom plate 1 by bolts, and the adjacent two bases 16 A hinge frame 17 is rotatably connected between them through a rotating shaft. The hinge frame 17 is used to lift the top plate 3 under the action of the hydraulic cylinder 18. The hinge frame 17 is connected to the inside of the fixed seat 48 through the rotating shaft. A hydraulic cylinder 18 is rotatably connected between them...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com