Optical fiber sensing system based on free-form surface off-axis reflection and measuring method

An optical fiber sensing system and off-axis reflection technology are applied in the direction of transmitting sensing components using optical devices, which can solve problems such as uncorrectable aberrations and inability to focus light, and achieve easy observation, wide wavelength range, and wide transmission bandwidth. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

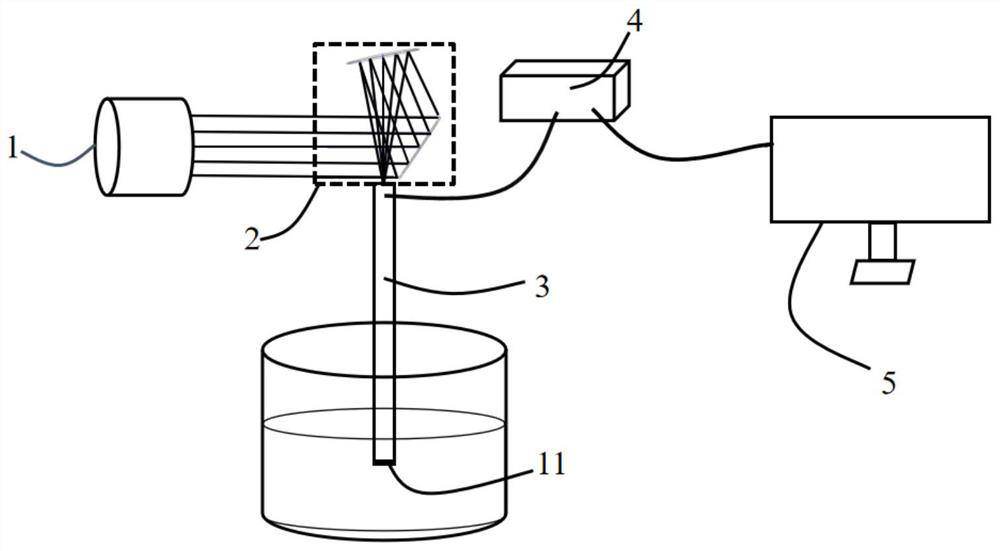

[0033] A four-wave mixing fiber optic sensing system based on free-form surfaces, such as figure 1 As shown, it includes: a continuous laser 1, an off-axis two-reflection optical system 2 based on a free-form surface, an optical fiber sensor 3, a spectrometer 4 connected to the output end of the optical fiber sensor, and a host computer 5 connected to the spectrometer; The laser light is coupled to the fiber optic sensor after being reflected and focused by an off-axis two-mirror optical system based on a free-form surface.

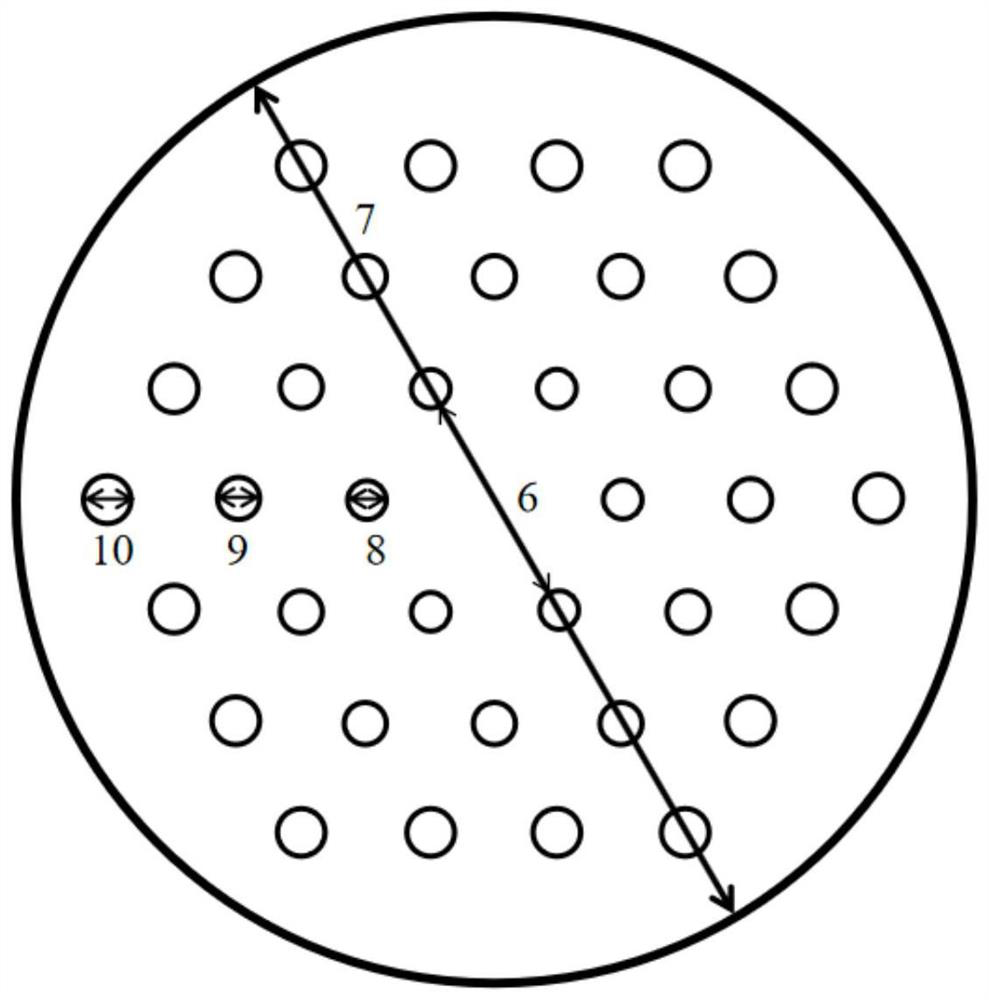

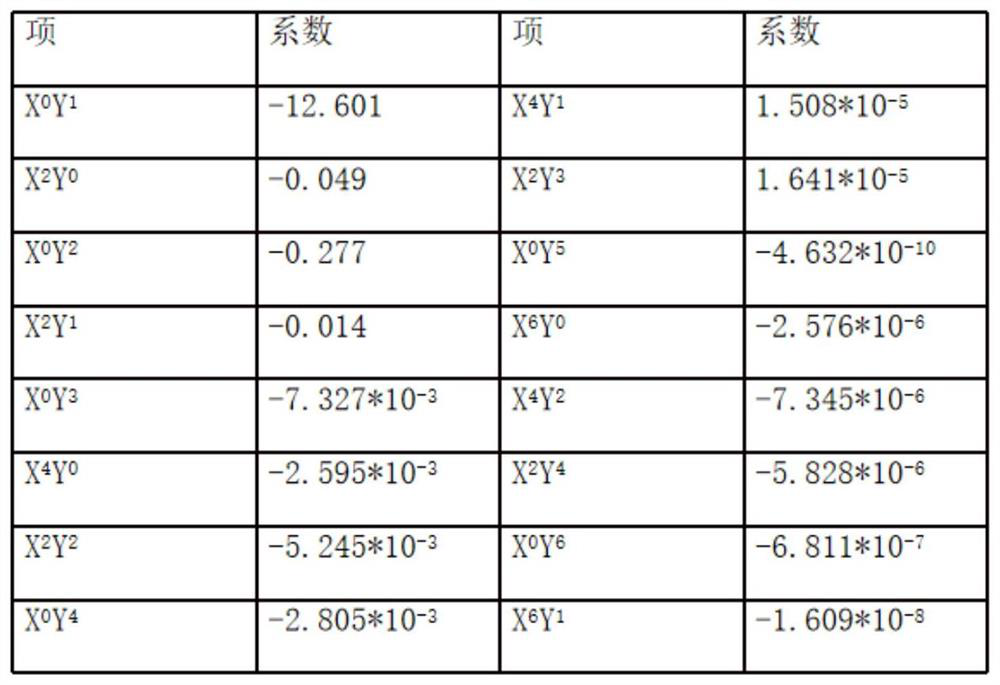

[0034] The off-axis two-mirror optical system based on a free-form surface includes a primary reflector and a secondary reflector. The primary reflector 12 is a hyperboloid with a radius of -60.7mm and an aspheric coefficient of -6.084. The secondary reflector 13 is an XY polynomial free-form surface, and it is a 6-degree free-form surface with a radius of 20mm and an aspheric coefficient of -8.399. The XY polynomial coefficients are as follows image 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius range | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com