Electric vehicle driving system with stepless speed changing function

A driving system and infinitely variable speed technology, which is applied in the direction of electric power devices, vehicle gearboxes, components with teeth, etc., can solve the problems of electric vehicle speed changes and inability to change gears, and achieve the effect of changing the speed of trams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025]The existing electric vehicle drive system generally has only one speed gear, and it is impossible to change the gear according to actual needs, thereby changing the speed change of the electric vehicle. Therefore, in this embodiment, the gearbox is set to realize the speed change of the electric vehicle. Variety.

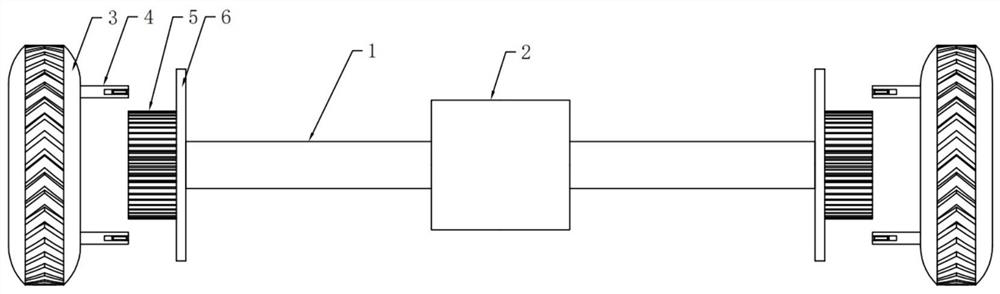

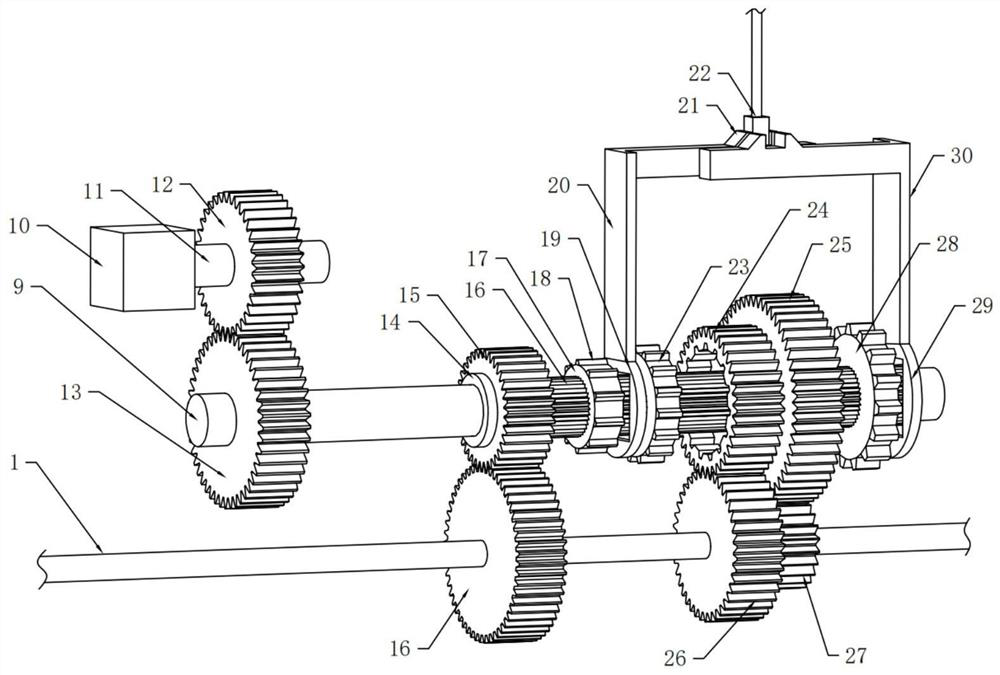

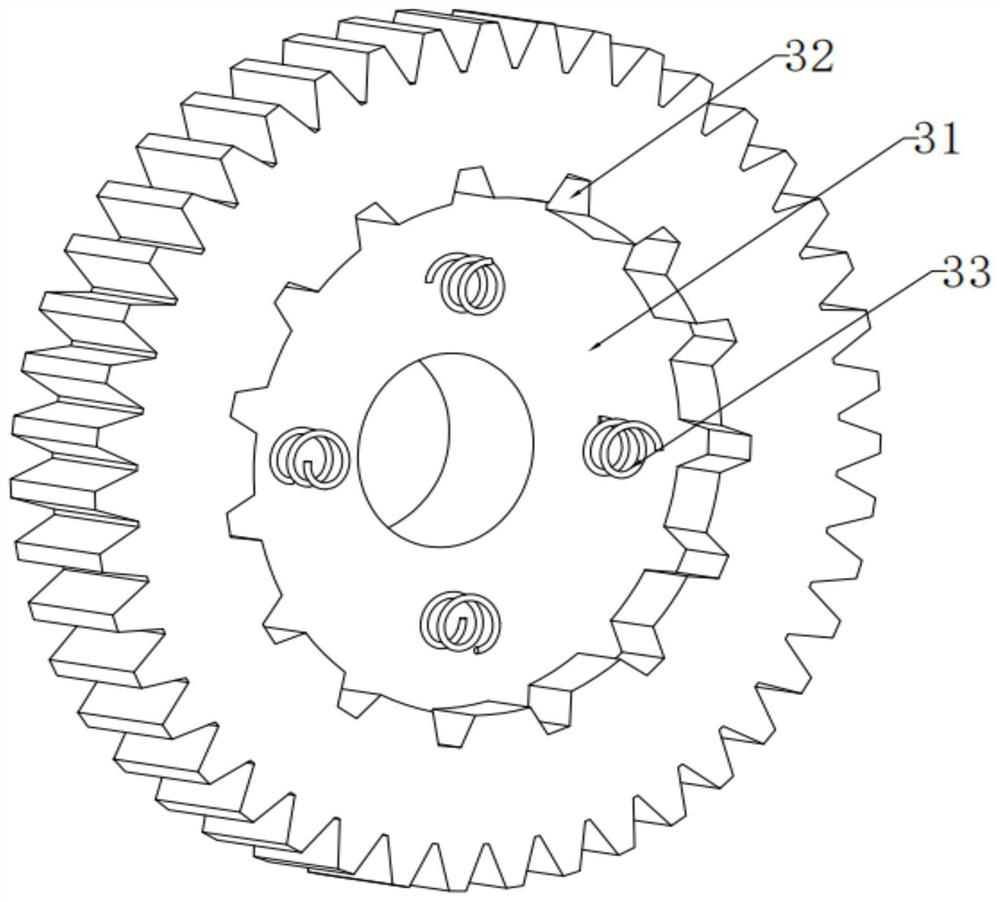

[0026]SeeFigure 1-3, An electric vehicle drive system with stepless speed change, comprising a drive shaft 1 and tires 3, the drive shaft 1 is provided with a gearbox 2, the gearbox 2 is rotatably connected with the drive shaft 1, the gearbox 2 One-speed driven gear 16, a second-speed driven gear 26, and a third-speed driven gear 27 are fixedly installed on the drive shaft 1 in turn from left to right. The gearbox 2 is rotatably connected with a first rotating shaft 9. The first rotating shaft 9 is fixedly mounted with a bearing 14. The bearing 14 on the first rotating shaft 9 is connected to the first-speed driving gear 15, the second-speed driving gear 24, and the t...

Embodiment 2

[0029]Existing drive shafts and tires are generally fixed by bolts. When maintenance is required, it is particularly difficult to disassemble, which makes it difficult to repair. Therefore, in this embodiment, a clamping assembly is provided to achieve more convenient disassembly and more convenient Maintenance.

[0030]SeeFigure 4 with5, The left and right ends of the drive shaft 1 are fixedly installed with second clamping teeth 5, the tire 3 is provided with a second clamping groove 8, and the second clamping teeth 5 are arranged corresponding to the second clamping groove 8, so The tire 3 is provided with a clamping assembly 4, the drive shaft 1 is fixedly mounted with a connecting disc 6, and the connecting disc 6 is provided with a fixing hole 7, and the clamping assembly 4 is arranged corresponding to the fixing hole 7, so The clamping assembly 4 includes a clamping rod 401, a second groove 402 is opened on the clamping rod 401, a clamping block 403 is rotatably connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com