Diesel generator set for realizing heat dissipation and noise reduction by adopting labyrinth branch air ducts

A diesel generator set, heat dissipation and noise reduction technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as increasing failure rate, shortening the life of electronic components, batteries and rubber parts, and uneven hot air flow. Improve insulation performance and service life, eliminate uneven heat dissipation, and reduce noise radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

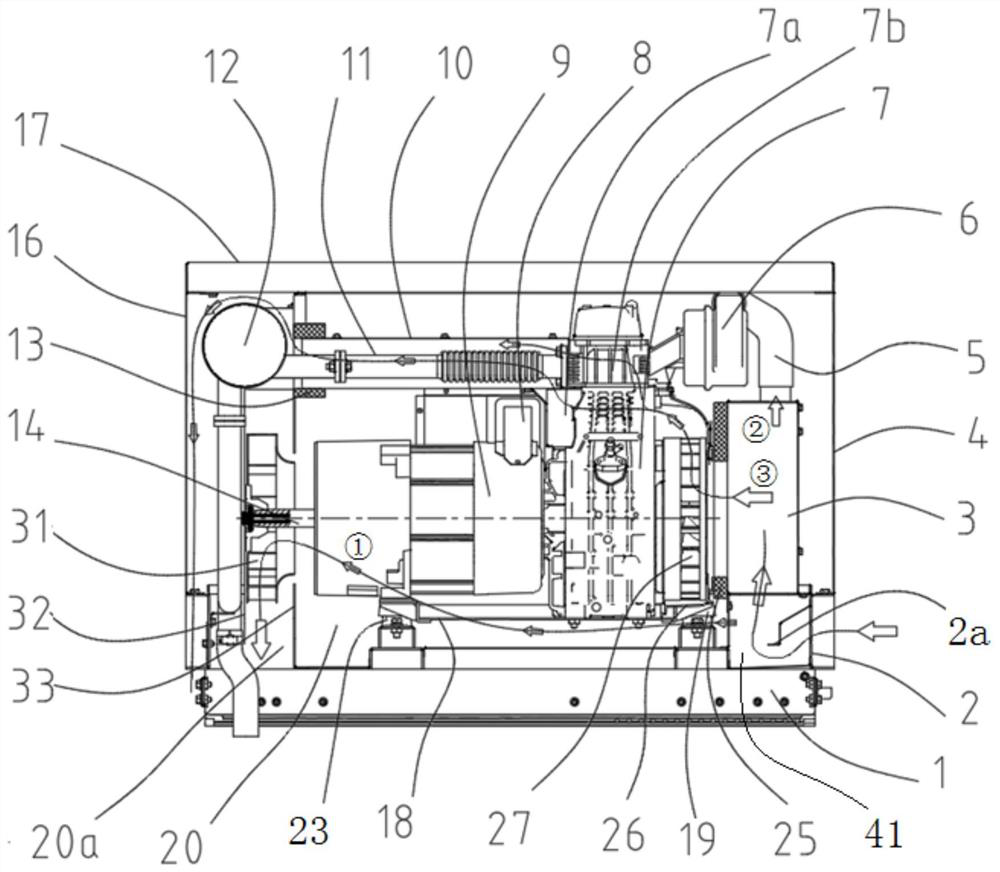

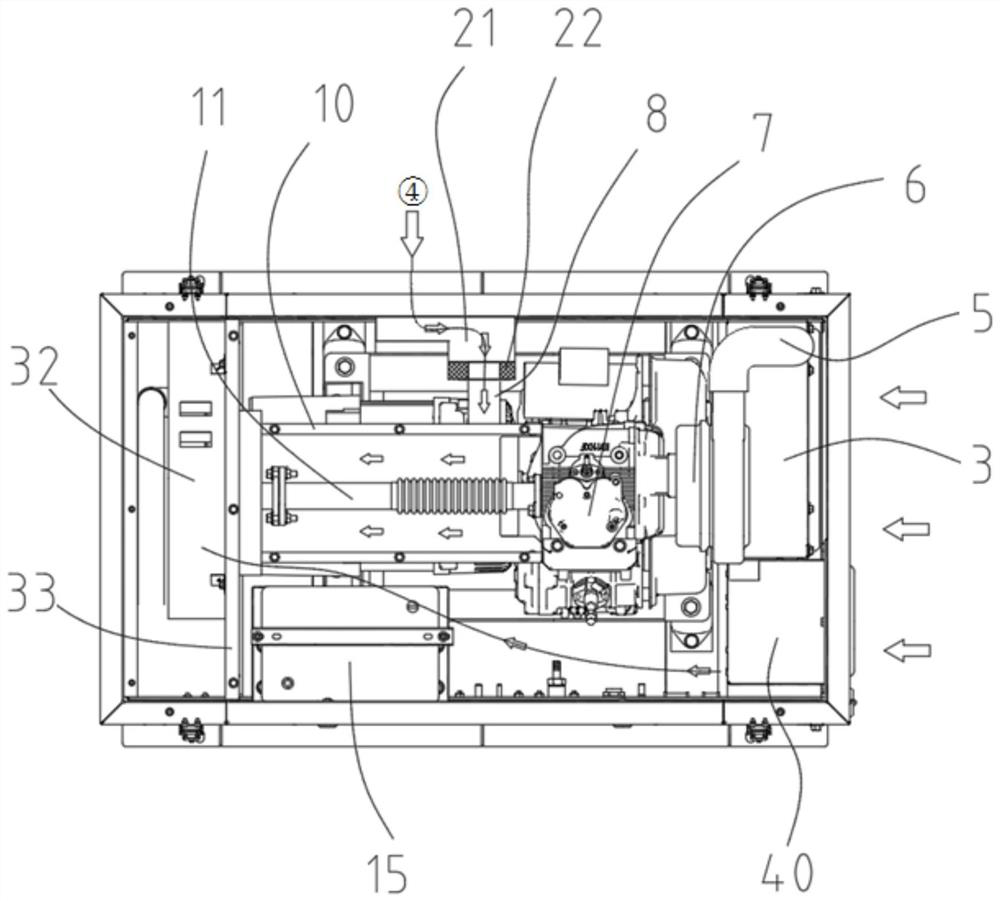

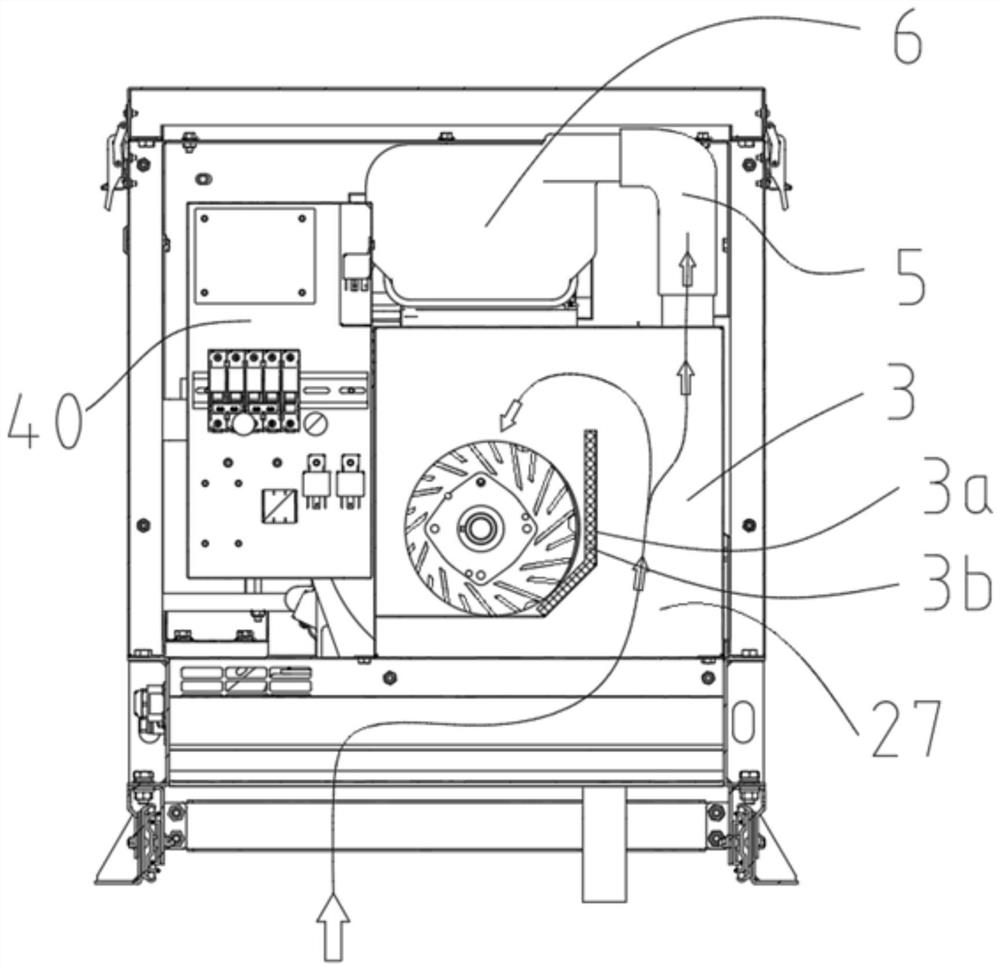

[0040] Such as Figures 1 to 5 Shown is an embodiment of a diesel generator set of the present invention that uses a labyrinth branch air duct to achieve heat dissipation and noise reduction, including a base 2 and a mute box connected to the base 2, and the mute box is provided with an intermediate The partition plate 33 divides the interior of the mute box body into a thermal insulation compartment 20a and a main engine compartment 20, and in the interior of the main engine compartment 20, air-cooled power generators are sequentially arranged in the direction from the thermal isolation compartment 20a to the main engine compartment 20. Engine 9, diesel e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com