Corrugated rock tunnel boring machine cutterhead with free surface assisting in rock breaking and preparation method of cutterhead

A tunneling and corrugated technology, applied in tunnels, manufacturing tools, mining equipment, etc., to achieve the effects of increasing strength and stiffness, improving rock breaking efficiency, and reducing the included angle of radial force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the purpose, technical effects and technical solutions of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention; obviously, the described embodiments It is a part of the embodiment of the present invention. Based on the disclosed embodiments of the present invention, other embodiments obtained by persons of ordinary skill in the art without making creative efforts shall all fall within the protection scope of the present invention.

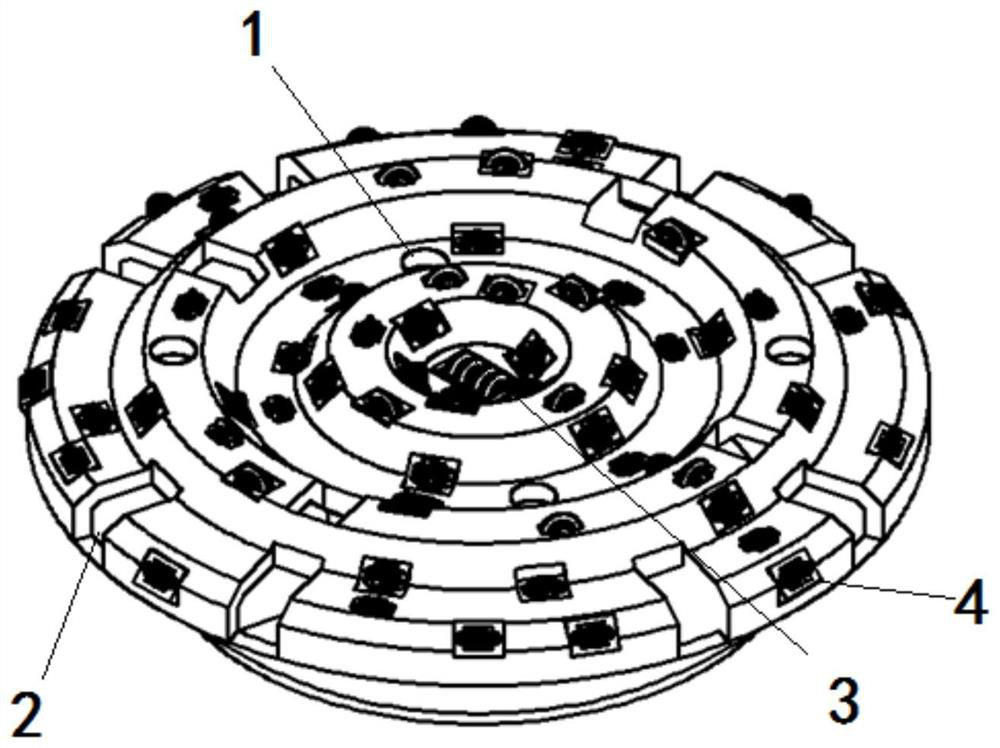

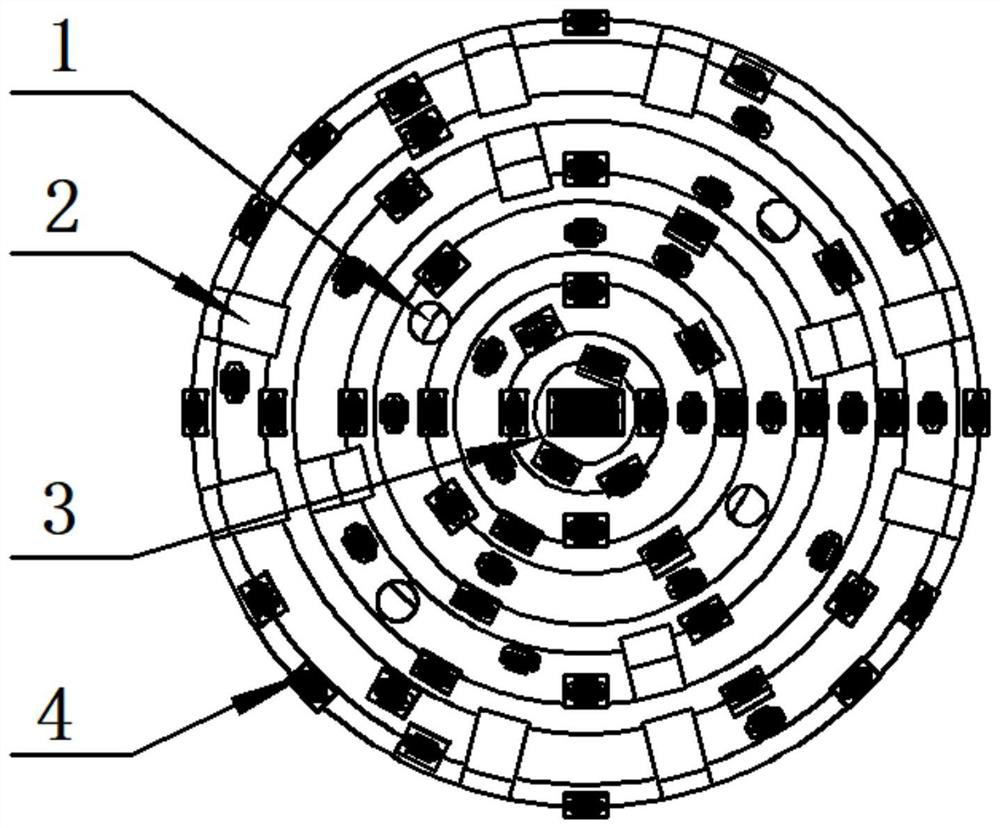

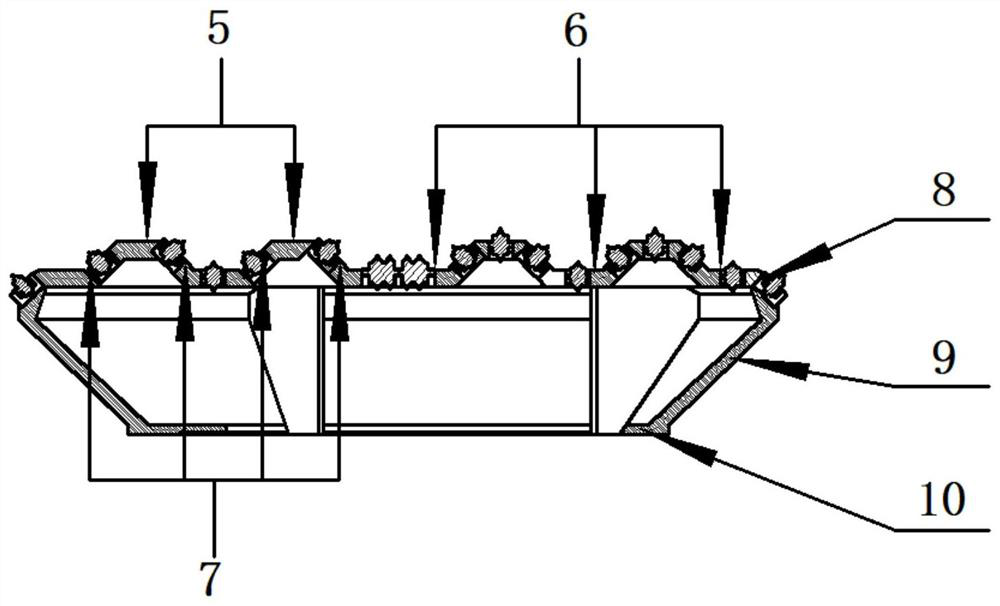

[0037] see figure 1 and figure 2 According to an embodiment of the present invention, a corrugated rock tunnel boring machine cutter head with free surface assisting rock breaking includes: a corrugated cutter head panel 8;

[0038]The corrugated cutterhead panel 8 is provided with a crest area 5, a trough area 6 and a trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com