Ferrite magnetic material and manufacturing method thereof

A technology of magnetic material and ferrite, applied in the field of ferrite, can solve the problems of high magnetic permeability and low magnetic loss, and achieve the effect of improving magnetic properties, increasing magnetic permeability and reducing lattice strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

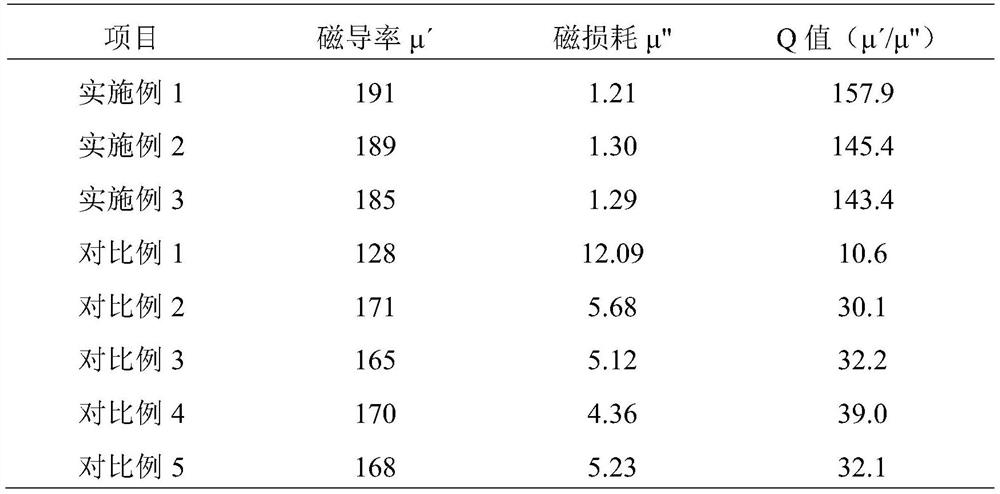

Examples

Embodiment 1

[0025] A ferrite magnetic material comprising a main component, an auxiliary component and an additive, the main component including Fe 2 o 3 、Mo 2 o 3 , Yb 2 o 3 , NiO and ZnO, the auxiliary components include WO 3 and Nd 2 o 3 ; Taking the amount of the main component as a benchmark, Fe in the main component 2 o 3 The content is 50mol%, Mo 2 o 3 The content is 20mol%, Yb 2 o 3 The content of NiO is 14mol%, the content of NiO is 10mol%, and the content of ZnO is 6mol%. Based on the weight of the main component, the WO in the auxiliary component 3 The content is 0.52wt%, Nd 2 o 3 The content of is 0.48wt%; The additive consists of V 2 o 5 , SiO 2 and CuO in a weight ratio of 1:2.5:1.5, and the additive accounts for 0.32wt% of the total weight percentage of the entire material.

[0026] The preparation method of above-mentioned ferrite magnetic material, comprises the steps:

[0027] S1. Mix, weigh Fe by molar percentage 2 o 3 、Mo2 o 3 , Yb 2 o 3 , NiO a...

Embodiment 2

[0039] A ferrite magnetic material comprising a main component, an auxiliary component and an additive, the main component including Fe 2 o 3 、Mo 2 o 3 , Yb 2 o 3 , NiO and ZnO, the auxiliary components include WO 3 and Nd 2 o 3 ; Taking the amount of the main component as a benchmark, Fe in the main component 2 o 3 The content is 52mol%, Mo 2 o 3 The content is 16mol%, Yb 2 o 3 The content of NiO is 12mol%, the content of NiO is 12.5mol%, and the content of ZnO is 7.5mol%. Based on the weight of the main component, WO 3 The content is 0.26wt%, Nd 2 o 3 The content is 0.15wt%; the additive consists of V 2 o 5 , SiO 2 and CuO in a weight ratio of 1:3:1, and the additive accounts for 0.5wt% of the total weight percentage of the entire material.

[0040] The preparation method of above-mentioned ferrite magnetic material, comprises the steps:

[0041] S1. Mix, weigh Fe by molar percentage 2 o 3 、Mo 2 o 3 , Yb 2 o 3 , NiO and ZnO, put them into a vibration...

Embodiment 3

[0053] A ferrite magnetic material comprising a main component, an auxiliary component and an additive, the main component including Fe 2 o 3 、Mo 2 o 3 , Yb 2 o 3 , NiO and ZnO, the auxiliary components include WO 3 and Nd 2 o 3 ; Taking the amount of the main component as a benchmark, Fe in the main component 2 o 3 The content is 48mol%, Mo 2 o 3 The content is 24mol%, Yb 2 o 3 The content of NiO is 12mol%, the content of NiO is 9mol%, and the content of ZnO is 7mol%. Based on the weight of the main component, the WO in the auxiliary component 3 The content is 0.62wt%, Nd 2 o 3 The content of is 0.12wt%; The additive consists of V 2 o 5 , SiO 2 and CuO in a weight ratio of 1:2:2, and the additive accounts for 0.25wt% of the total weight percentage of the entire material.

[0054] The preparation method of above-mentioned ferrite magnetic material, comprises the steps:

[0055] S1. Mix, weigh Fe by molar percentage 2 o 3 、Mo 2 o 3 , Yb 2 o 3 , NiO and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com