Roller carrier for wind power tower drum machining

A technology of wind power towers and roller frames, which is applied in the field of roller frames, and can solve the problems of single function of roller frames, deviation of symmetrical centers, and poor versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

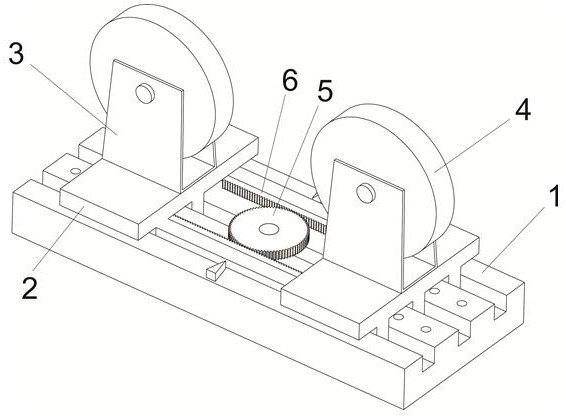

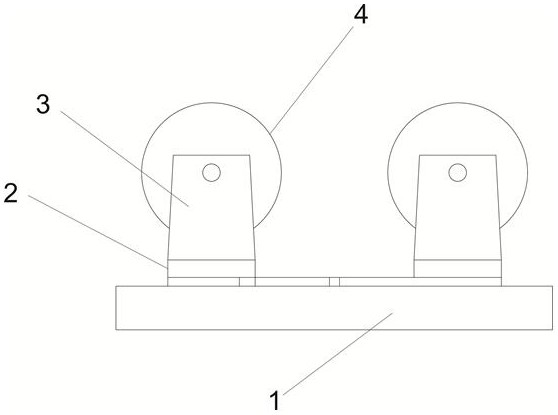

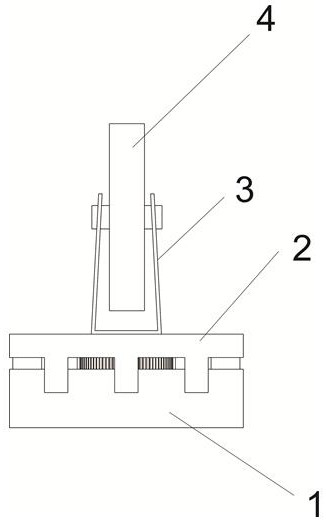

[0023] Such as Figure 1-4 As shown, this embodiment is a roller frame for processing wind power towers, including a base 1, a mobile skateboard 2, a roller support seat 3 and a roller 4, the base 1 is provided with a chute 11, and the mobile skateboard 2 is arranged on the base 1, and move along the direction of the chute 11; the mobile slide 2 is provided with a roller support seat 3, and the roller 4 is arranged on the roller support seat 3. The roller frame of this embodiment also includes a gear 5 and a rack 6, and the rack 6 Installed on the mobile slide 11, the gear 5 is installed on the base 1, and the rack 6 cooperates with the gear 5 to realize the linkage between the mobile slide 11 and the gear 5.

[0024] The mobile slide 11 is divided into two left and right sides. The racks 6 on the two mobile slides 2 are arranged in parallel, and the gear 5 is clamped in the middle. When the gear 5 rotates, the two racks 6 are driven to move in opposite directions, and the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com