Workbench for casting machining and using method

A workbench and casting mold technology, which is applied in the direction of manufacturing tools, casting equipment, metal processing equipment, etc., can solve the problems of easy damage to the workpiece, unfavorable use, complicated process, etc., to achieve refined structure, improved quality, and easy to turn over the box Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

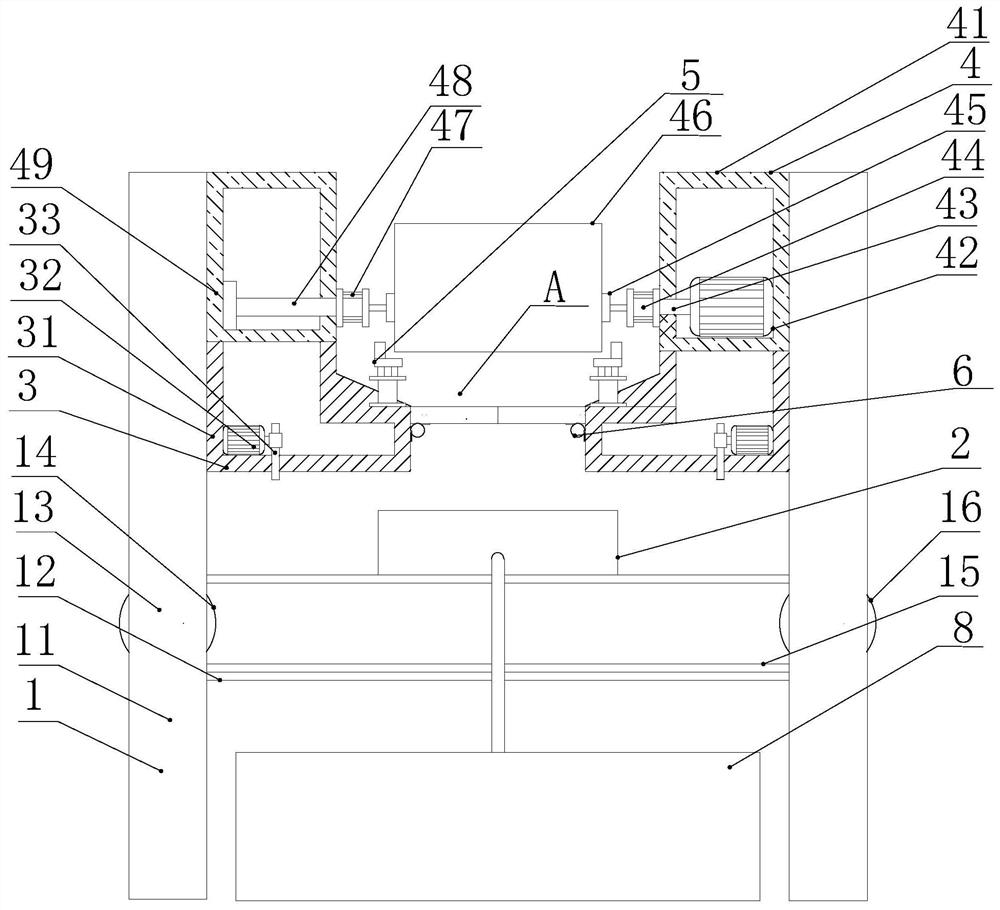

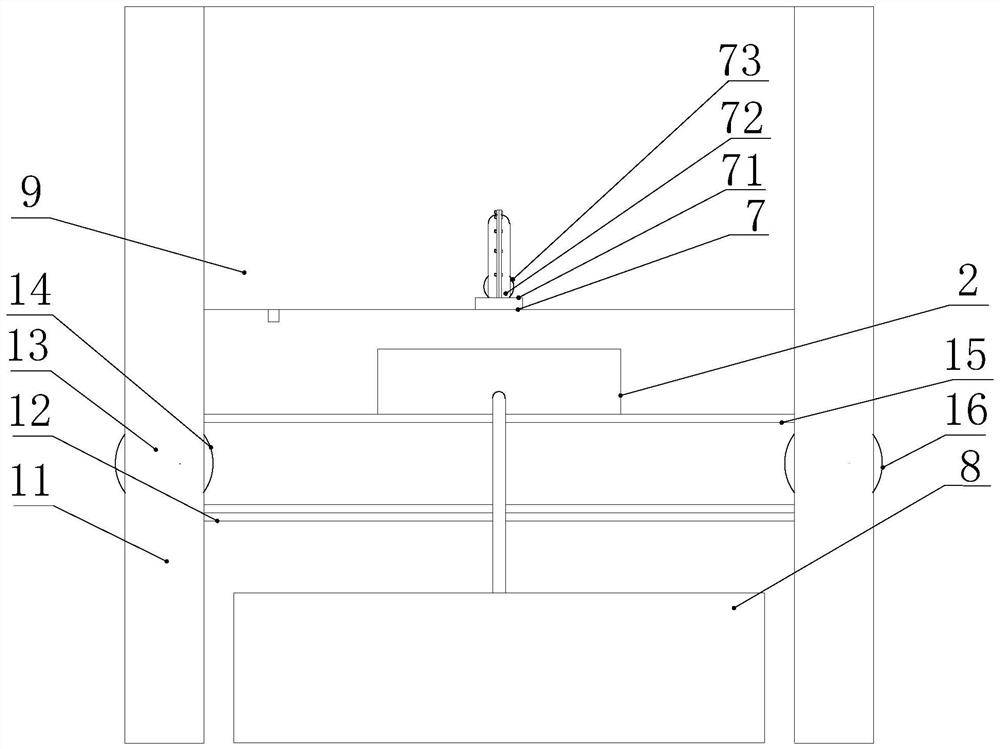

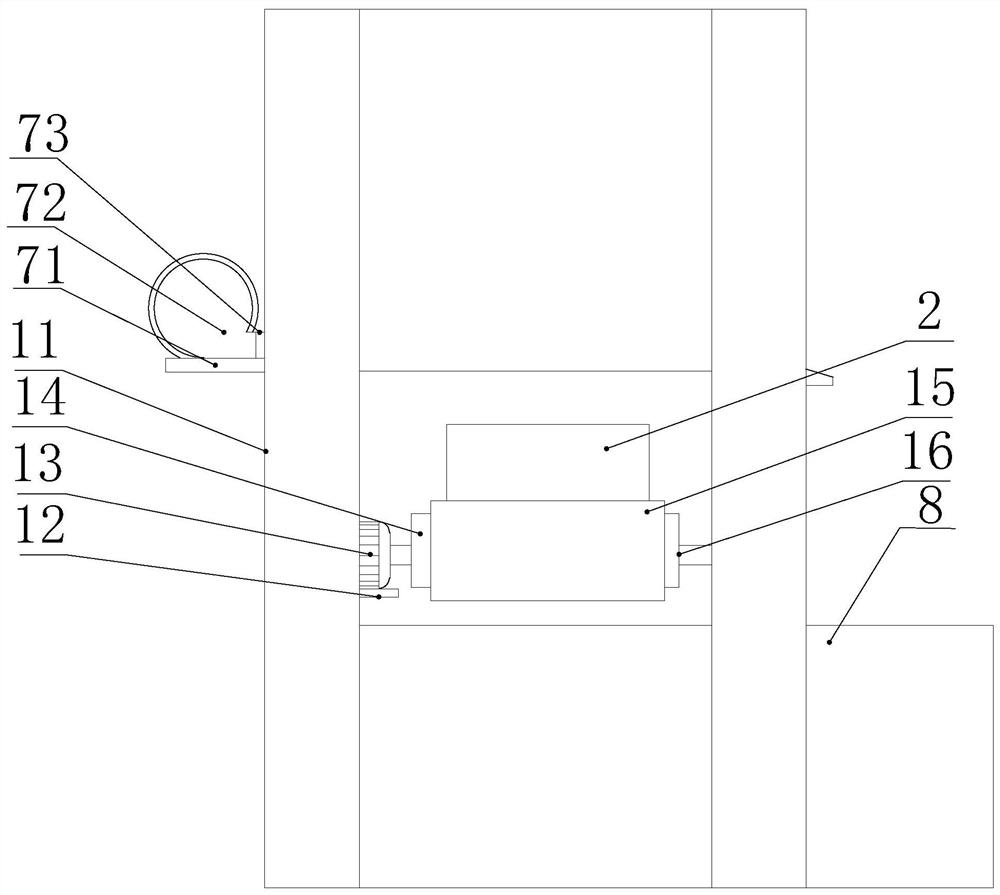

[0032] Example: such as Figure 1-6 As shown, the present invention is a workbench for casting and using method, including a moving mechanism 1, the top of the moving mechanism 1 is provided with a collecting box 2, which is convenient to drive the collecting box 2 to move through the moving mechanism 1, and one end of the moving mechanism 1 is provided with The cooling mechanism 3 facilitates the reduction of the temperature of the workpiece and prevents the temperature from being too high, causing the workpiece to burn the worker. The end of the moving mechanism 1 away from the cooling mechanism 3 is provided with a clamping mechanism 4, and the casting mold 46 is clamped by the clamping mechanism 4. The cooling mechanism 3 and The clamping mechanism 4 is provided with an electric telescopic rod 5, which drives the casting mold 46 to move up and down through the cooling mechanism 3 and the clamping mechanism 4, and a discharge mechanism 6 is arranged between the cooling mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com