A Convenient Ultrasonic Automatic Cleaner

An automatic cleaning and easy-to-operate technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning methods using liquids, etc. Quick, easy to place and collect, to avoid the effect of rusting again

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

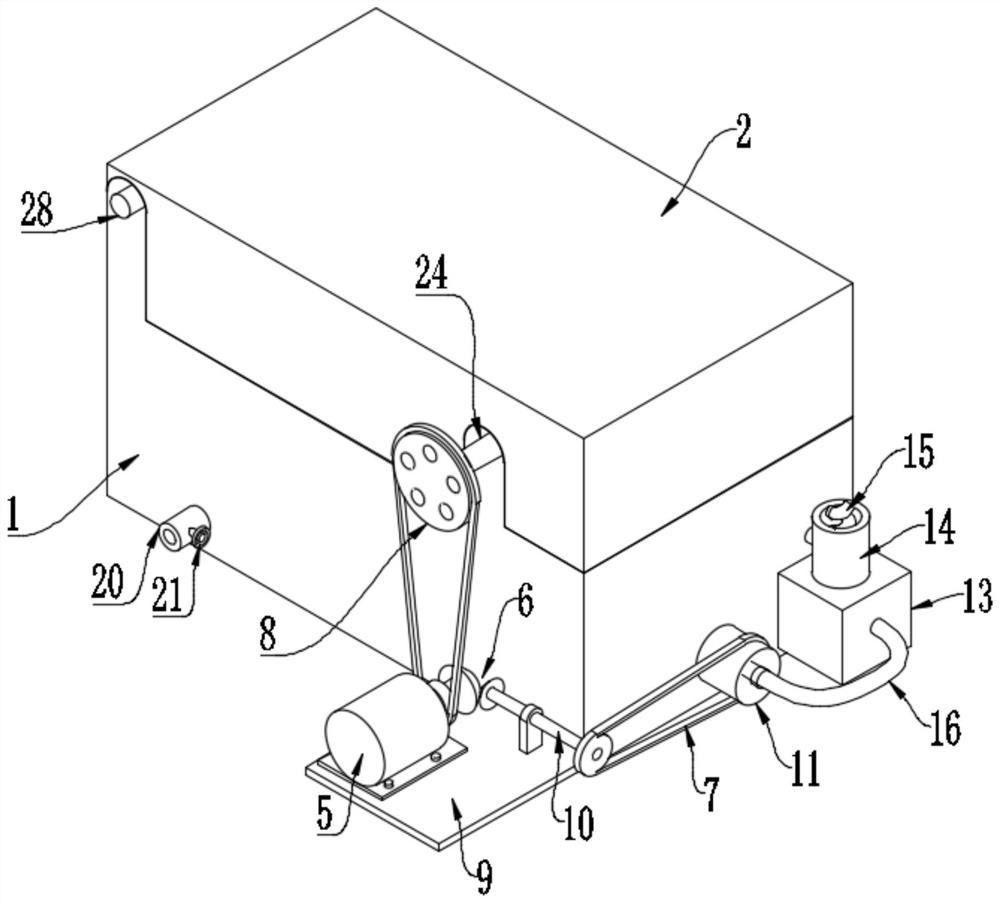

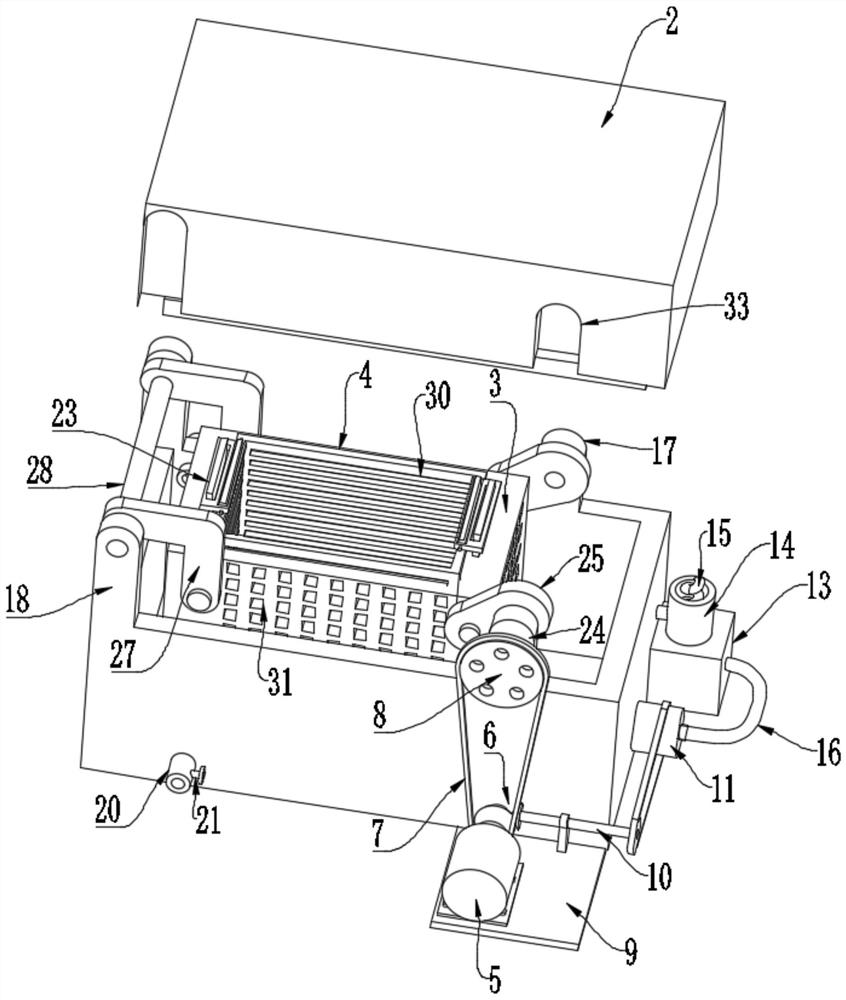

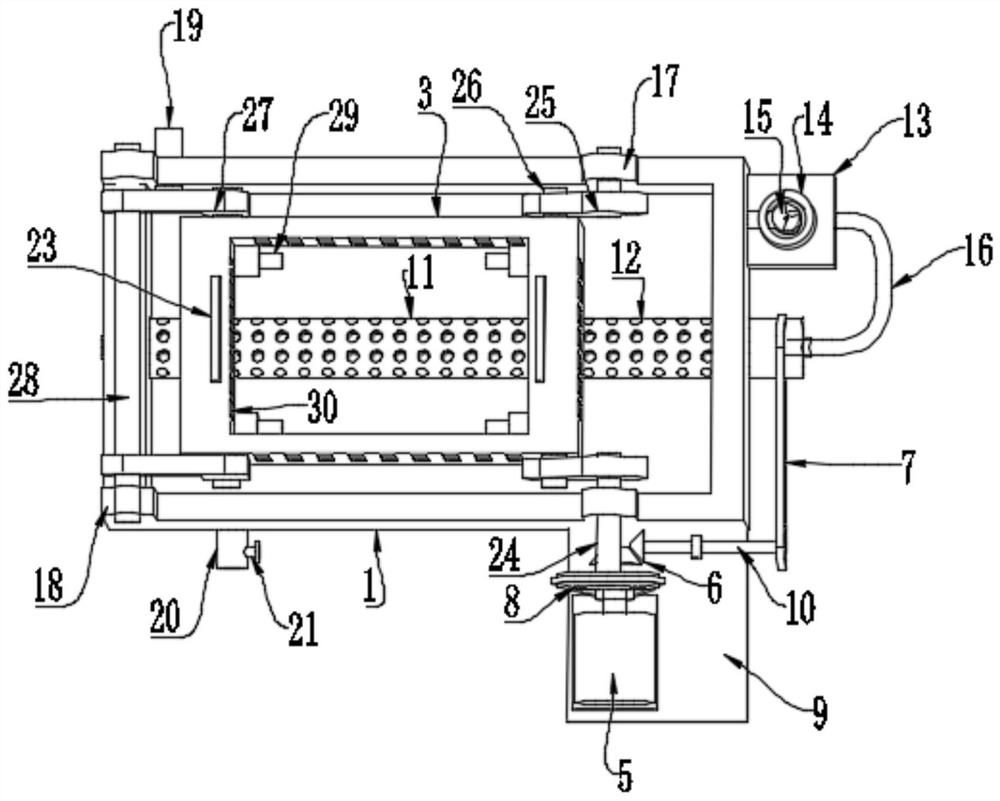

[0025] see Figure 1-7 , in an embodiment of the present invention, a conveniently operated ultrasonic automatic cleaner includes a cleaning tank 1, and also includes a tank cover 2 sealingly matched with the cleaning tank 1, and the cleaning tank 1 is provided with a receiving frame 3, an ultrasonic transducer 29 and the shaft cylinder 11, the receiving frame 3 is connected with the cleaning tank 1, the receiving frame 3 has no bottom, and the receiving frame 3 is provided with a cleaning frame 4, and the cleaning frame 4 is used to hold the parts to be cleaned. put, the cleaning frame 4 and the receiving frame 3 follow the movement, the side wall and the bottom of the cleaning frame 4 are evenly arranged with a plurality of first penetration holes 30, and the outer wall of the cleaning tank 1 is equipped with a motor 5 through a support plate 9 , the output end of the motor 5 is connected to the pulley 8 through the belt 7, the pulley 8 is installed on one end of the first m...

Embodiment 2

[0034] This embodiment is optimized on the basis of Embodiment 1.

[0035] The part of the moisture discharge pipe located in the air intake pipe of the fan is in a spiral shape.

[0036] The working principle of drying in the present invention: open the valve 21 to discharge the cleaning medium, cover the tank cover 02, and the corresponding positioning groove 33 is provided on the tank cover 02, which is convenient for installation and positioning, and a sealing ring is provided at the junction of the tank cover 02 and the receiving frame 3 22 ensures the airtightness of the interior during drying, start the motor 5 and the hot air blower 13, the motor 5 drives the second main shaft 10 to rotate through the bevel gear pair 6, the second main shaft 10 drives the shaft cylinder 11 to rotate through the belt 7, and the air passes through the heat The fan 13 is heated and enters the shaft cylinder 11 through the air pipe 16, and escapes into the closed cleaning tank 1 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com