Industrial rust-proof rapid oil brushing device for gears

An industrial and gear technology, which is applied in the field of industrial gear anti-rust quick oil brushing devices, can solve the problems of inability to automatically apply oil, waste of anti-rust oil, and inability to automatically discharge materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

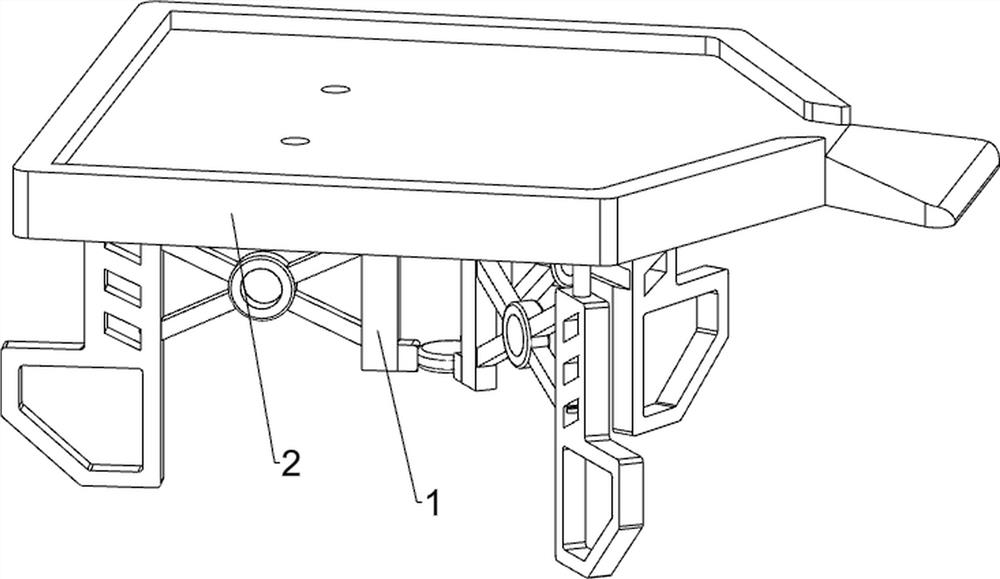

[0077] An industrial anti-rust fast oil brushing device for gears, such as figure 1 and figure 2 As shown, it includes a base 1, a placement plate 2, a clamping mechanism 3 and an oil brushing mechanism 4. The upper side of the base 1 is connected to the placement plate 2, the upper side of the placement plate 2 is connected to the clamping mechanism 3, and the right side of the placement plate 2 is connected to There is an oil brushing mechanism4.

[0078] When the device needs to be used, the user can place the gear on the clamping mechanism 3 and apply anti-rust oil on the oil brushing mechanism 4. At this time, the clamping mechanism 3 rotates inward and moves downward to achieve the gear Fastened and fixed to facilitate subsequent operations, and then the user can reverse the clamping mechanism 3 and the oil brushing mechanism 4 to achieve the purpose of applying anti-rust oil to the gears. When it is necessary to adjust the height of the anti-rust oil, the user The oi...

Embodiment 2

[0080] On the basis of Example 1, such as image 3 and Figure 4 As shown, the clamping mechanism 3 includes a guide rail 31, a slider 32, a clamping rod 33, a first spring 34, a support assembly 35, a first bearing 36 and a turntable 37, and the middle part of the upper side of the placement plate 2 is connected with the first bearing 36. , the first bearing 36 is rotatably connected with a turntable 37, the outer side of the turntable 37 is connected with a guide rail 31, the bottom side of the guide rail 31 is in contact with the upper side of the placement plate 2, and a plurality of sliders 32 are slidably connected in the guide rail 31, and the slider 32 A clamping rod 33 is rotatably connected inside, a plurality of first springs 34 are wound around the guide rail 31 , and a support assembly 35 is connected to the lower side of the clamp rod 33 , and the support assembly 35 is slidingly connected to the guide rail 31 .

[0081] When the device needs to be used, the use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com